- Home

- »

- Next Generation Technologies

- »

-

Smart Factory Market Size, Share & Growth Report, 2030GVR Report cover

![Smart Factory Market Size, Share & Trends Report]()

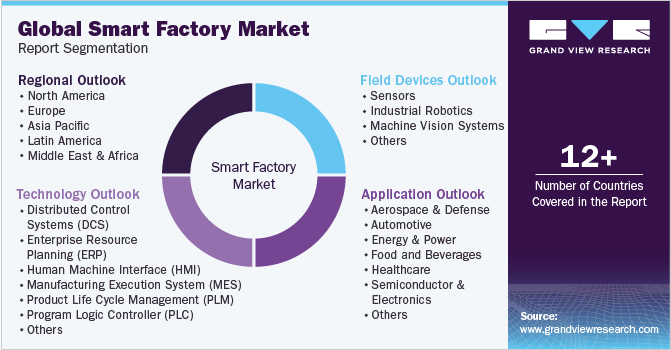

Smart Factory Market Size, Share & Trends Analysis Report By Technology (DCS, ERP, HMI, MES, PLM, PLC, SCADA), By Field Devices (Sensors, Industrial Robotics, Machine Vision Systems), By Application, By Region, And Segment Forecasts, 2023 - 2030

- Report ID: GVR-4-68040-124-7

- Number of Pages: 150

- Format: Electronic (PDF)

- Historical Range: 2018 - 2021

- Industry: Technology

Report Overview

The global smart factory market size was valued at USD 130.25 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030.The market for smart factory is expected to expand due to several key factors, including increasing emphasis on energy efficiency, improved manufacturing productivity, and the establishment of advanced manufacturing infrastructures. Additionally, there are promising prospects for the adoption of collaborative robots and ongoing advancements in 3D printing technology, which are set to create lucrative opportunities for the market during the forecast period.

Artificial intelligence (AI) and machine learning (ML) are playing a pivotal role in smart factories. These technologies enable predictive maintenance, quality control, and process optimization. AI-driven analytics can uncover valuable insights from vast datasets, helping manufacturers make data-driven decisions. As AI capabilities continue to evolve, their integration into smart factories is expected to grow.

For instance, in September 2022, Datametrex AI Ltd. announced the launch of Smart Factory AI technology based on big data, Artificial Intelligence (AI), and server automation operating system technologies. Additionally, the company claimed to receive purchase orders totaling CAD 200,000 from various multinational corporations, including Woongjin, Co. Ltd., Kolon Benit, and Lotte Data Communication Co., Ltd.

The adoption of Industry 4.0 principles is a prominent trend in smart factories. Industry 4.0 emphasizes the integration of digital technologies such as IoT, big data analytics, and automation into manufacturing processes. Smart factories are leveraging these technologies to optimize production, improve quality, and enhance overall efficiency. This trend is expected to continue as manufacturers seek to remain competitive in a globalized market.

Furthermore, the Internet of Things (IoT) is the backbone of smart factories, facilitating real-time monitoring and control of machines and processes. The growing number of connected devices, sensors, and actuators is enhancing visibility and automation within factories. The increasing deployment of 5G networks and the advancement of edge computing will further strengthen the significance of IoT in the market.

The COVID-19 pandemic had a profound impact on the smart factory industry. While it initially disrupted supply chains and manufacturing operations, it also accelerated the adoption of digital technologies in factories. The need for remote monitoring, predictive maintenance, and agile production processes became apparent during the pandemic, driving increased investment in smart factory solutions. Additionally, the emphasis on worker safety and social distancing led to a greater interest in automation and robotics. The market is anticipated to sustain its growth momentum as the global economy recovers from the pandemic. This is attributed to manufacturers placing greater emphasis on enhancing resilience, efficiency, and operational flexibility in their processes.

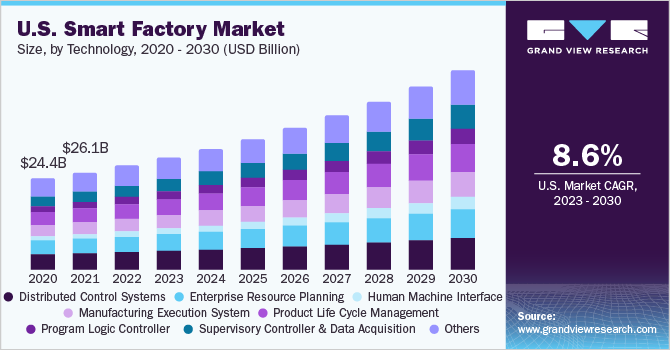

Technology Insights

The distributed control systems (DCS) technology segment accounted for a significant market share of over 17% in 2022, driven by its pivotal role in enhancing industrial automation and process optimization.DCS technology offers scalability and seamless integration with emerging technologies like IoT and Industry 4.0, and the ability to facilitate remote monitoring and control, which became increasingly important during the COVID-19 pandemic. Moreover, they contribute to safety compliance, energy efficiency, and modernization of legacy control systems, aligning with broader industry trends of efficiency, sustainability, and digital transformation in production operations.

The human-machine interface (HMI) technology segment is expected to register the highest CAGR of 12.6% over the forecast period, owing to the enhanced user experience and operational efficiency within smart factories. HMIs are evolving to offer intuitive, user-friendly interfaces, often incorporating touchscreen and gesture control, making interactions more accessible and efficient for operators. With the increasing complexity of smart factory systems, the demand for advanced HMI solutions that facilitate seamless human-machine interactions and data visualization is on the rise, driving the segment’s substantial growth.

Application Insights

The automotive segment accounted for the largest market share of over 27% in 2022. The automotive industry is increasingly adopting smart factory solutions to meet rising consumer demand for customizations, advanced safety features, and eco-friendly vehicles. Smart factories offer automation, data analytics, and real-time monitoring capabilities that are crucial for streamlining production processes, ensuring high product quality, and meeting stringent regulatory standards. Additionally, the shift towards electric and autonomous vehicles necessitates more advanced manufacturing processes, making smart factories a strategic choice for automotive manufacturers aiming to enhance productivity, reduce costs, and remain competitive in a rapidly evolving market.

The food and beverages segment is expected to expand at the fastest CAGR of over 13% during the forecast period in the global smart factory market, driven by a combination of consumer demand for food safety & quality and regulatory requirements. Smart factories in this sector are increasingly adopting automation, IoT sensors, and data analytics to ensure precise quality control, efficient production, and compliance with strict food safety standards.

Additionally, the need for traceability and real-time monitoring to address food recalls and supply chain disruptions has made smart factory solutions essential for the industry. The integration of these technologies helps manufacturers enhance product consistency, reduce waste, and respond quickly to changing market demands, thus fueling strong segment growth.

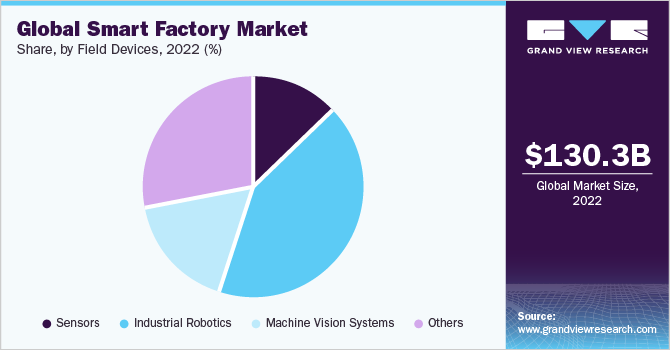

Field Devices Insights

The industrial robotics segment accounted for the largest market share of over 41% in 2022. Industrial robots are increasingly preferred by manufacturers due to their ability to enhance production efficiency, reduce human labor costs, and improve product quality. They offer precision, speed, and consistency in tasks such as assembly, welding, and material handling, making them indispensable in smart factories striving for higher productivity, quality, and competitiveness. Additionally, advancements in robotic technology, including collaborative robots (cobots) that can collaborate with human workers, have accelerated their adoption in various industries, fueling segment growth.

The sensors segment is expected to register the fastest growth rate of 11.5% over the forecast period. As smart factories increasingly rely on data-driven decision-making and automation for efficiency and competitiveness, sensors play a critical role in providing the necessary data inputs. Advancements in sensor technologies have led to smaller, more accurate, and cost-effective sensors, making it feasible to deploy them extensively within manufacturing processes. Thus, the greater connectivity and intelligence in factories drive the robust growth of sensors in the market.

Regional Insights

The Asia Pacific regional market captured the highest revenue share of over 35% in 2022. Asia Pacific has emerged as a manufacturing hub, particularly in countries like China, Japan, and South Korea, where there is a strong emphasis on industrial automation and technological advancements. Additionally, the region's growing population has led to increased consumer demand for various products, including automobiles and electronics, driving the need for efficient and high-capacity manufacturing. Moreover, government initiatives and investments in Industry 4.0 and smart factory technologies have further accelerated the adoption of the market in the region.

The Latin America region is expected to expand significantly at a CAGR of over 10% during the forecast period. Latin America is witnessing increasing industrialization and a rising focus on manufacturing efficiency. To remain competitive in the global market, businesses in this region are adopting smart factory technologies to enhance productivity, optimize resources, and improve product quality. Furthermore, there is a steadily growing investment in sectors such as automotive, electronics, and aerospace, which are increasingly incorporating smart factory practices to meet international standards and cater to both domestic and export markets. This is expected to drive the growth of the regional market.

Key Companies & Market Share Insights

The market is classified as highly competitive, with the presence of several smart factory players. The key players operating in the industry are focusing on strategic alliances, product developments, expansions, and mergers & acquisitions to remain competitive. For instance, in March 2023, Schneider Electric SE, a digital transformation provider of energy management and industrial automation, initiated the construction of its upcoming smart factory in Dunavesce, Hungary. This state-of-the-art facility, backed by an investment of USD 42.67 million (€40 million), would cover an area of 25,000 sq. m. and will accommodate a workforce of 500 employees. Such strategies by key players are anticipated to augment market growth over the forecast period. Following are some of the major players in the global smart factory market:

-

ABB, Ltd.

-

Dassault Systemes S.E.

-

FANUC Corporation

-

General Electric Company

-

Honeywell International, Inc.

-

Johnson Controls, Inc.

-

KUKA AG

-

Mitsubishi Electric Corporation

-

Rockwell Automation, Inc.

-

Schneider Electric SE

-

Canon Inc.

-

Cisco System Inc.

-

Emerson Electric Co.

Smart Factory Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 141.59 billion

Revenue forecast in 2030

USD 271.91 billion

Growth rate

CAGR of 9.8% from 2023 to 2030

Base year for estimation

2022

Historical data

2018 - 2021

Forecast period

2023 - 2030

Quantitative units

Revenue in USD Billion and CAGR from 2023 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Technology, field devices, application, region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.; Canada; Germany; U.K.; France; Italy; Spain; China; India; Japan; South Korea; Brazil; Mexico; Saudi Arabia; UAE

Key companies profiled

ABB, Ltd.; Dassault Systemes S.E.; FANUC Corporation; General Electric Company; Honeywell International, Inc.; Johnson Controls, Inc.; KUKA AG; Mitsubishi Electric Corporation; Rockwell Automation, Inc.; Schneider Electric SE; Canon Inc.; Cisco System Inc.; Emerson Electric Co.

Customization scope

Free report customization (equivalent to up to 8 analyst working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Smart Factory Market Report Segmentation

This report forecasts revenue growth at the global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the global smart factory market report on the basis of technology, field devices, application, and region:

-

Technology Outlook (Revenue, USD Billion, 2018 - 2030)

-

Distributed Control Systems (DCS)

-

Enterprise Resource Planning (ERP)

-

Human Machine Interface (HMI)

-

Manufacturing Execution System (MES)

-

Product Life Cycle Management (PLM)

-

Program Logic Controller (PLC)

-

Supervisory Controller and Data Acquisition (SCADA)

-

Others

-

-

Field Devices Outlook (Revenue, USD Billion, 2018 - 2030)

-

Sensors

-

Industrial Robotics

-

Machine Vision Systems

-

Others

-

-

Application Outlook (Revenue, USD Billion, 2018 - 2030)

-

Aerospace & Defense

-

Automotive

-

Energy & Power

-

Food and Beverages

-

Healthcare

-

Semiconductor & Electronics

-

Oil & Gas

-

Others

-

-

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

-

Europe

-

U.K.

-

Germany

-

France

-

Italy

-

Spain

-

Rest of Europe

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Rest of Asia Pacific

-

-

Latin America

-

Brazil

-

Mexico

-

Rest of Latin America

-

-

Middle East & Africa (MEA)

-

UAE

-

Saudi Arabia

-

Rest of Middle East & Africa

-

-

Frequently Asked Questions About This Report

b. The global smart factory market size was estimated at USD 130.25 billion in 2022 and is expected to reach USD 141.59 billion in 2023.

b. The global smart factory market is expected to witness a compound annual growth rate of 9.8% from 2023 to 2030 to reach USD 271.91 billion by 2030.

b. The industrial robotics segment accounted for the largest market share of over 41% in 2022. Manufacturers increasingly prefer industrial robots due to their ability to enhance production efficiency, reduce human labor costs, and improve product quality.

b. Some key players operating in the smart factory market include ABB, Ltd., Dassault Systemes S.E., FANUC Corporation, General Electric Company, Honeywell International, Inc., Johnson Controls, Inc., KUKA AG, Mitsubishi Electric Corporation, Rockwell Automation, Inc., Schneider Electric SE, Canon Inc., Cisco System Inc., Emerson Electric Co.

b. The smart factory market is expected to grow substantially due to several key factors, including increasing emphasis on energy efficiency, improved manufacturing productivity, and the establishment of advanced manufacturing infrastructures.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."