- Home

- »

- Plastics, Polymers & Resins

- »

-

Vinyl Acetate Monomer Market Size & Share Report, 2020GVR Report cover

![Vinyl Acetate Monomer Market Size, Share & Trends Report]()

Vinyl Acetate Monomer Market Size, Share & Trends Analysis Report By Application (Polyvinyl Acetate, Polyvinyl Alcohol, Ethylene Vinyl Acetate, Ethylene Vinyl Alcohol), By Region, And Segment Forecasts, 2015 - 2020

- Report ID: 978-1-68038-302-7

- Number of Pages: 80

- Format: Electronic (PDF)

- Historical Data: 2010-2012

- Industry: Bulk Chemicals

Report Overview

The global vinyl acetate monomer market size was valued at USD 6,719.1 million in 2014. It is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2015 to 2020, in terms of revenue. The growth of the global adhesives industry on account of increasing demand from major end-use industries such as furniture automobiles and construction is expected to remain a key driving factor for the global vinyl acetate monomer (VAM) market over the next six years.

Vinyl acetate is one of the most important monomers widely used for manufacturing adhesives owing to the enhanced adhesive, fiber-forming, optical and electrical properties. It is a significant chemical building material that is used for manufacturing industrial and consumer products.

VAM is a precursor used in polymer and copolymer manufacturing for consumer and industrial products including PVA/PVAc (polyvinyl acetate/polyvinyl acetals), PVOH (polyvinyl alcohol), EVA (ethylene vinyl acetate), and EVOH (ethylene vinyl alcohol).

Growing demand for paints & coatings on account of an increase in infrastructure spending particularly in emerging economies of Asia Pacific and Latin America is expected to have a positive influence on the global vinyl acetate monomer market growth over the forecast period. Vinyl acetate ethylene (VAE) copolymers are ideal for architectural coating owing to low environmental impact. Other benefits include low solvent demand, low monomer residue, and developed without alkylphenol ethoxylate (APEO) raw materials & formaldehyde feedstock.

Increasing shale gas exploration & production (E&P) activities, particularly in the U.S. is expected to ensure a continuous supply of key raw materials for manufacturing VAM. Crude oil is a major feedstock for ethylene production which in turn is feedstock for VAM. Natural gas derived from shale gas has a high percentage of ethane in comparison to crude oil for VAM production. This factor is expected to increase VAM production in the U.S. and further meet the export and domestic demand.

Stringent regulations owing to growing environmental concerns and volatile prices of key raw materials are expected to remain key challenges for market participants. Increasing demand for photovoltaic (PV) cells and the growth of the global food packaging industry are expected to provide future opportunities to VAM market participants.

EVA copolymer resins are used for PV cells for providing a protective, adhesive layer between the glass and electronic components. EVA also provides structural support and helps in insulating PV cells from harmful elements such as rain, dirt, and wind.

Application Insights

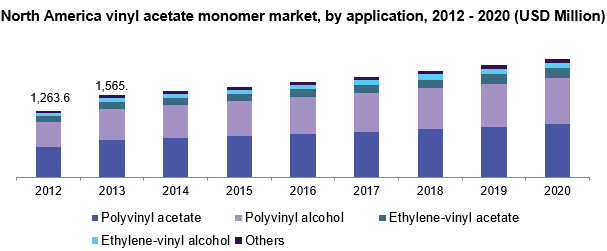

In 2013, polyvinyl acetate emerged as the largest application segment which occupied the market share of 45.4%, in terms of value. About 80% of VAM produced is used for PVA and PVOH production. PVA and PVOH dominated the application segment of the vinyl acetate monomer market. PVA is the largest derivative of VAM and is majorly used in adhesive applications owing to good adhesion properties to various substrates such as wood, paper, metals, and plastic films. Other major use of PVA includes paints & coatings. PVOH is the second-largest VAM consumer derived from PVA. PVOH is used in applications such as coatings, adhesives, and water-soluble packaging.

PVAc derived from PVA is used for producing magnetic wire insulation, safety glass interlayer, wash primers, and coating. EVA is expected to grow at steady rates over the next six years owing to an increase in demand from packaging industry segments. EVA is also used in the manufacturing of footwear and shower curtains. EVOH is expected to be the fastest-growing application owing to usage as barrier resin for plastic bottles, food packaging, engineering polymers, and gasoline tanks. VAM is also used in the manufacturing of polyvinyl butyral (PVB) and VAE. PVB is used in safety glass production used in buildings and automobiles.

Regional Insights

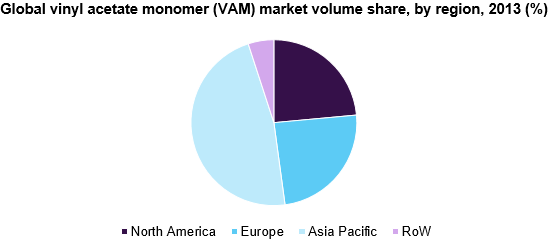

Asia Pacific emerged as the leading regional vinyl acetate monomer market and accounts for close to half of the total market volume. Asia Pacific is expected to continue leading the global market on account of the growth of major end-use industries in the region.

Emerging markets such as China and India are expected to witness higher growth rates owing to increasing adhesives and paints & coatings demand from the infrastructure industry. Increasing consumption of adhesives for food packaging along with growing demand from the automotive industry is projected to bolster the market growth over the forecast period.

In 2013, North America emerged as the fastest-growing market for vinyl acetate monomer. North America is expected to overtake Europe to become the second-largest VAM consumer by 2020. A positive outlook on the U.S.’s packaging industry coupled with the shale gas boom in the nation is expected to remain a key driving factor for the growth of the regional market.

Key Companies & Market Share Insights

The global market is moderately consolidated with the top four companies accounting for just over 50% of the total market. Increasing demand for emerging economies of Asia Pacific is projected to compel the manufacturers to increase their production capacities. Manufacturers are focused on achieving higher participation in the value chain to gain a competitive edge.

Leading manufacturers compete on the basis of price differentiation and services offered. Some major companies operating in the global VAM market include Celanese, Dairen Chemical Corporation, Sinopec, and LyondellBasell Industries. Other companies include The Dow Chemical Company, Kuraray, Sipchem, Ningxia Yinglite.

Recent Development

-

In November 2021, Celanese Corporation collaborated with Mitsubishi Chemical Advanced Materials. This collaboration allowed both companies to work together to convert waste streams into saleable and end-product formulations, so that customers could get more sustainable options to reduce carbon emissions.

Vinyl Acetate Monomer Market Report Scope

Report Attribute

Details

Market size value in 2019

USD 9.32 billion

Revenue forecast in 2020

USD 9.86 billion

Growth Rate

CAGR of 5.7% from 2015 to 2020

Base year for estimation

2014

Historical data

2013

Forecast period

2015 - 2020

Quantitative units

Revenue in USD billion and CAGR from 2015 to 2020

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Germany, China, France, India, Brazil, UAE

Key companies profiled

Celanese, Dairen Chemical Corporation, Sinopec and LyondellBasell Industries.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Frequently Asked Questions About This Report

b. The global vinyl acetate monomer market size was estimated at USD 9.32 billion in 2019 and is expected to reach USD 9.86 billion in 2020.

b. The global vinyl acetate monomer market is expected to grow at a compound annual growth rate of 5.7% from 2015 to 2020 to reach USD 9.86 billion by 2020.

b. Asia Pacific dominated the vinyl acetate monomer market with a share of 46.9% in 2019. This is attributable to growth of adhesives demand from furniture, automobiles, and construction industries.

b. Some key players operating in the vinyl acetate monomer market include Celanese, Dairen Chemical Corporation, Sinopec and LyondellBasell Industries.

b. Key factors that are driving the market growth include growth of global adhesives industry on account of increasing demand from major end-use industries such as furniture automobiles and construction.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."