- Home

- »

- Plastics, Polymers & Resins

- »

-

Engineering Adhesives Market Size, Share, Industry Report, 2019-2025GVR Report cover

![Engineering Adhesives Market Size, Share & Trends Report]()

Engineering Adhesives Market Size, Share & Trends Analysis Report; By Product (Epoxies, Polyurethanes, Cyanoacrylates, Methacrylates); By Application; By Region, And Segment Forecasts, 2019 - 2025

- Report ID: 978-1-68038-612-7

- Number of Pages: 185

- Format: Electronic (PDF)

- Historical Range: 2014 - 2017

- Industry: Bulk Chemicals

Industry Insights

The global engineering adhesives market was valued at USD 19.41 billion in 2018 and is expected to witness a CAGR of 7.2% from 2019 to 2025. Rising demand from end-use industries including construction, transportation, and electronics around the world is catalyzing the growth of the market.

Increased demand for engineering adhesive products has been observed in Asia Pacific. This demand is attributed to the growth of industrial output in emerging countries such as China and India. The replacement of conventional fasteners with bonding products has observed widespread applications in construction, transportation, and other sectors.

Development in fermentation and microbial processes has led to the advancement of polyurethane adhesive products. This, in turn, is projected to create new market opportunities for vendors. This factor is important in the growth of the market owing to the requirement for specialty products and market differentiation in end-use industries.

These products are gaining popularity owing to properties such as rigid bonds, high strength, and high viscosity. These can be manufactured with various processes based on natural or synthetic formulations. Natural based include sources such as dextrin or vegetable starch, natural resins, animal hides, and other materials.

Engineering adhesive plays a key role in improvising the quality and reliability of equipment & machinery. These products help to achieve more dynamic and static strength and reduce corrosion problems during assembly. Applications such as gaskets, thread locking, and sealing have witnessed an increasing demand for such products.

Structural bonding in engineering applications is anticipated to create new opportunities for market participants. Dissimilar substrates such as plastic, metal, and glass can be glued using advanced bonding products. They offer advantages such as uniform stress distribution, reduction in weight, and improved fatigue resistance.

Product Insights

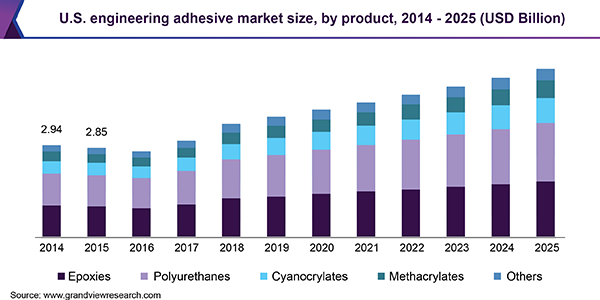

In terms of volume, epoxies accounted for the highest market share of 36.5% in 2018 and are projected to grow at a lucrative pace over the next seven years. These products provide a high degree of freedom and are an ideal choice where structural linkage is required. Applications such as potting terminals and hinges & brackets widely use these types of products.

Cyanoacrylates segment is projected to grow at a CAGR of 7.8% from 2019 to 2025 in terms of revenue. The low shearing strength of these products enables their use in temporary bonding applications. Cyanoacrylates products have wide applications in electronics, woodworking, medical, cosmetics, and marine applications.

The demand for polyurethanes is increasing on account of their ability to join a wide range of substrates. These products also provide high strength and are suitable in numerous sealing and bonding applications. Growing demand from equipment & machinery and construction industries are the key drivers for this segment.

Application Insights

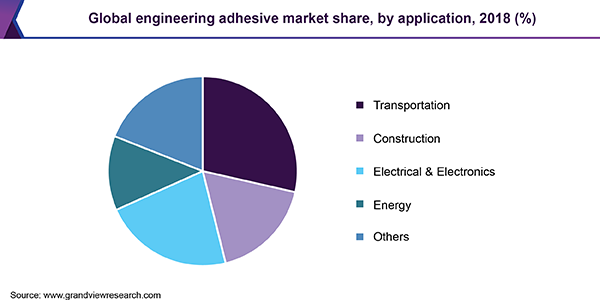

On the basis of application, the engineering adhesives market has been categorized into transportation, construction, electrical & electronics, energy, and others. Transportation was the largest segment in 2018 and accounted for a volume share of 28.7%. The application is driven by rising demand for joining vehicle components in assemblies and the replacement of fasteners with adhesive products.

Government funding and investment in promoting the renewable energy sector. Among this sector, wind energy is projected to provide ample opportunities for adhesive producers over the forecast period. Emerging economies such as India and China are providing special attention to the sector owing to the massive energy potential. As per India’s Ministry of New and Renewable Energy, the country ranks in 5th and 4th positions for solar and wind capacities around the world respectively. It has also announced to produce around 40% of power from the renewable energy sector by 2030.

Infrastructure plays a key role in harnessing the broad development goals and economic growth of the country. As per UNCTAD’s 2018 report, between 2015 to 2030 there is an investment need of around USD 1.6 to 2.5 trillion per year. However, the current investment is around USD 870 billion per year. The rising need for infrastructure investment over the coming years is projected to remain a focus area for many governments. This is likely to benefit the engineering adhesive industry as construction is one of the key consumers of bonding products.

Regional Insights

Asia Pacific is projected to grow at the highest CAGR of 8.8% over the forecast period in terms of revenue. This growth is attributed to the massive Chinese industrial sector including construction, automotive, energy, and electronics. Wind energy is one of the fastest-growing sectors in China and around the world. Manufacturing of wind turbine blades involves wide usage of adhesive products. As per Global Energy Council, China is the leading country in terms of wind power capacity both on land and sea. Also, as per China’s 13th Energy Technology Innovation, Five Year Plan, wind energy capacity in the country is projected to reach 210 gigawatts by 2020.

In terms of volume, Europe held a 23.5% market share in 2018. Production in transportation including automotive, aerospace, and marine sector is projected to drive the market in the country. As per the Aerospace & Defense Industries Association in Europe, the aerospace & defense sector has an annual turnover of around USD 247 billion. There is a significant demand for adhesive products for the bonding of composites, metals, and plastics in this sector.

North America accounted for a volume share of 21.2% in 2018. Growing consumption in the packaging & automotive industries is a major driver of the market. The woodworking industry is projected to create many opportunities for vendors on account of the requirement of structural bonding applications.

Engineering Adhesives Market Share Insights

The global engineering adhesive industry is dominated by multinational companies with their presence across different stages of the value chain. Integration in the value chain allows these companies to reduce the operations and procurement costs and diversify their business in various end-use industries.

Major market participants include Henkel AG & Co. KGaA, H.B. Fuller Company, Permabond LLC, 3M, and Dymax Corporation among others. Advanced formulations and innovative products are anticipated to remain key strategies for market vendors.

Report Scope

Attribute

Details

Base year for estimation

2018

Actual estimates/Historic data

2014 - 2017

Forecast period

2019 - 2025

Market representation

Volume in Kilotons, Revenue in USD Million & CAGR from 2019 to 2025

Regional scope

North America, Europe, Asia Pacific, Central & South America, Middle East & Africa

Country scope

U.S., Canada, Mexico, Germany, UK, China, India, Japan, Brazil

Report coverage

Revenue forecast, company share, competitive landscape, growth factors, and trends

15% free customization scope (equivalent to 5 analyst working days)

If you need specific market information, which is not currently within the scope of the report, we will provide it to you as a part of customization

Segments Covered in the ReportThis report forecasts revenue growth at the global and regional levels and provides an analysis of the industry trends in each of the submarkets from 2014 to 2025. For the purpose of this study, Grand View Research has segmented the engineering adhesives market report based on the product, application, and region:

-

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2014 - 2025)

-

Epoxies

-

Polyurethanes

-

Cyanoacrylates

-

Methacrylates

-

Others

-

-

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2014 - 2025)

-

Transportation

-

Construction

-

Electrical & Electronics

-

Energy

-

Others

-

-

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2014 - 2025)

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

-

Asia Pacific

-

China

-

India

-

Japan

-

-

Central and South America

-

Brazil

-

-

Middle East & Africa

-

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."