- Home

- »

- Plastics, Polymers & Resins

- »

-

Global Resorcinol Market Share, Trends Report, 2019-2025GVR Report cover

![Resorcinol Market Size, Share & Trends Report]()

Resorcinol Market Size, Share & Trends Analysis Report By Application (Rubber Products, Wood Adhesives, UV Stabilizers, Flame Retardants), By Region, And Segment Forecasts, 2018 - 2025

- Report ID: GVR-1-68038-969-2

- Number of Pages: 86

- Format: Electronic (PDF)

- Historical Range: 2014 - 2018

- Industry: Bulk Chemicals

Report Overview

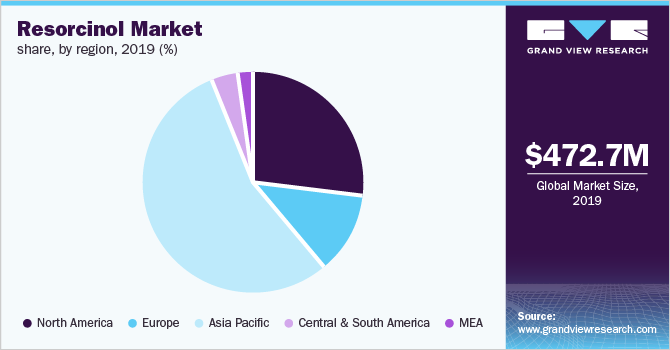

The global resorcinol market size was valued at USD 472.7 million in 2019 and is expected to expand at a compound annual growth rate (CAGR) of 3.4% from 2019 to 2025. Its growing usage in applications such as rubber, wood adhesives, and UV stabilizers coupled with the inherent advantages of the chemical is expected to propel market growth.

Resorcinol is also called as 1,3-Benzenediol. It is a chemical, specifically used for adhesion purposes. It is obtained from the crystallization of benzene and is soluble in ether, alcohol, and water. The application industries of the chemical include dyestuff, personal care, pharmaceuticals, plastic, and rubber.

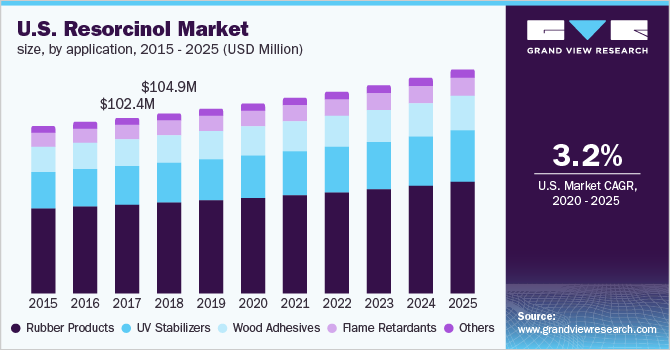

The resorcinol market worth in the U.S. was USD 107.0 million in 2019 and is forecasted to be USD 130.6 million by 2025 growing at an anticipated CAGR of 3.2% over the forecast period. The presence of a strong automotive and construction sector in the country coupled with the prevalent awareness of its usage is expected to benefit the overall demand in the country.

Resorcinol is used as a medium for adhesion between rubber and reinforcing cords. The rubber products for which it is used include belt, tire, and rubber-coated fabric. All these materials are widely utilized in the automotive industries. The increasing disposable income across the globe has catered to a rise in the demand for automotive vehicles. Such trends are expected to benefit product demand over the forecast period.

Resorcinol-formaldehyde resins are used for wood binding applications to address issues such as room temperature cure and structural integrity. The usage of the resin also imparts waterproof characteristics to the applied wood surface. Also, it serves as an intermediate for the manufacturing of light screening agents used for protecting plastics against UV lights. The chemical is also used to manufacture pharmaceutical products, flame retardants, fungicidal creams & lotions, and agriculture chemicals. The broad application portfolio of the product has benefitted the chemical demand in the recent past, and this scenario is expected to continue over the forecast period.

Resorcinol Market Trends

The global automotive industry has experienced growth across the globe in the recent past due to factors such as rising disposable income, and competitive strategies adopted by major automotive manufacturers and this trend are expected to continue over the next eight years. The rise in the automotive industry has spurred a surge in demand for rubber products such as tires, and belts. Resorcinol is widely used in these products thus the demand for the same is expected to get benefit due to the rise in automotive sales.

Rapid urbanization is a key factor that has played an important role in contributing to the automobile demand in the recent past and is presumed to continue to support the market shortly. The passenger vehicles segment is witnessing a higher growth rate as compared to commercial vehicles because of rising disposable income and growing population.

In 2018, wood adhesives emerged as the second fastest growing application segment in the global resorcinol market. This can be attributed to the increasing wood-based construction activities. Resorcinol is resistant to acids, solvents, oil, and saltwater. It has the capacity to withstand a range of temperatures after curing. In addition, it acts as a strong adhesive, which is the major factor behind the utilization of resorcinol in wood.

Resorcinol-formaldehyde and resorcinol are widely used to improve the adhesion between rubbers in tire manufacturing. Increased adhesion results in the escalation of the dynamic as well as static modulus of rubber. Resorcinol does not have any effect on the vulcanization of rubber, and it improves adhesion between the steel cord and synthetic fiber or cord.

Resorcinol based flame retardants can be used in various high-quality plastics owing to enhanced processing characteristics. Regulations favoring the use of flame retardants and increasing awareness regarding the benefits associated with resorcinol-based flame retardants are anticipated to propel the market growth over the coming years.

UV stabilizers emerged as the second largest application segment in the global resorcinol market in 2018. Resorcinol is used as an intermediate chemical to produce specialty chemicals, which are further used as screening agents in plastics. Resorcinol-based UV absorbers have strong chemical stability, owing to which they are extensively used in adhesives, plastics, elastomers, and coatings.

Resorcinol is used for various purposes such as wood adhesives, for manufacturing UV light stabilizers, as well as in the production of rubber products. However, the usage of resorcinol has adverse health effects. Inhalation of vapors or dust of resorcinol may cause respiratory tract irritation. Due to the health hazards of the product, the packaging and labeling of the chemical have to be done by the prescribed rules and regulations. Additionally, the product has high disposal cost and is regulated by various rules and regulations. Such factors are expected to restrain the market growth of the product over the forecast period.

Application Insights

Rubber products dominated the application segment in 2019, and it is expected that the application will continue its dominance over the forecast period. The global market is growing on account of broadening the application portfolio of the chemical. Companies, develop the products which comply with the prevalent rules and regulations.

Resorcinol is widely used for tire manufacturing for a variety of applications such as automotive tires, bicycles, and aircraft. The usage of chemical improves the overall rubber compound processability. It also results in the increase of static as well as dynamic modulus of rubber. Also, it does not have any effect on the overall vulcanization process of rubber and enhances the steel cord adhesion. Such inherent advantages are expected to benefit the segment demand growth over the next eight years.

Resorcinol is used in wood applications due to its high chemical stability. It is resistant to solvents, salt water, acids, and oil. It acts as a strong adhesive and can withstand a wide range of temperatures after curing. Wood-based interior, as well as exterior structures, are in high demand for architectural as well as construction applications. The global growth in both of these major end-use industries is forecasted to benefit the overall demand for wood adhesive application, and the segment is anticipated to be valued at USD 82.0 million by 2025.

The chemical is widely used as a raw material for the manufacture of UV absorbers. UV absorbers are used in a variety of applications such as plastics, adhesives, coatings, as well as elastomers to protect them from the effects of UV light. The global growth in the demand for these applications particularly in Asia Pacific is expected to benefit the overall UV stabilizers segment growth.

Resorcinol based flame retardants mostly fall in the non-halogenated flame retardant category. They show high heat stability & low volatility and can tolerate high processing temperatures. Due to its better processing characteristics, the flame retardants manufactured by using resorcinol can be used in a variety of high flow plastics. The favorable regulations favoring the usage of flame retardants coupled with the advantages of resorcinol based flame retardants are expected to favor the segment growth.

Regional Insights

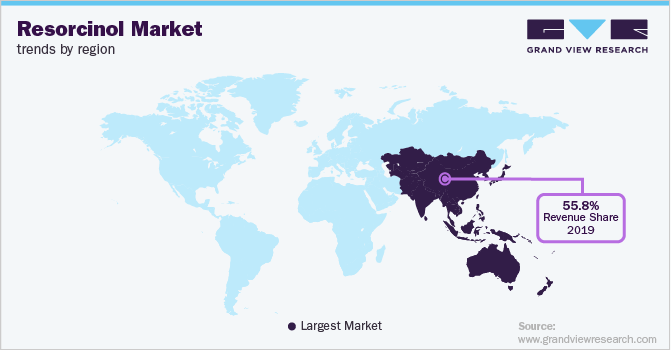

Regarding revenue, Asia Pacific held the major market share in 2019 and is expected to continue its dominance over the next eight years. The market worth in the region was USD 263.7 million in 2019. Rapid industrialization in India & China and the positive growth of the automotive sector in the region are contributing positively to the overall demand growth. The government of various countries has taken initiatives in the region to promote and revitalize the construction industry in the region. Such trends are expected to have a positive effect on market growth in the region.

Asia Pacific dominated the global market with the share of 55.5% in 2016. Asia Pacific is characterized by rapid industrialization in developing nations such as China and India. Increasing young population coupled with rising middle-class income in the region has led to growth in industrial trade and boosted the number of vehicles. Moreover, government initiatives and reforms, such as GST, are expected to propel the growth of automotive as well as the manufacturing sector. Thus, the growing automobile industry is anticipated to positively impact the overall resorcinol demand for manufacturing automobile tires in the Asia Pacific.

In 2016, China accounted for the largest share of more than 48.6% of the resorcinol market in the Asia Pacific. Increasing population and high rate of urbanization are the major factors responsible for the rapid growth of automobile, construction, and furniture industries in the country. Over the past few years, China has emerged as the largest manufacturing hub in the Asia Pacific owing to low-cost labor and favorable government policies.

The European market worth was USD 54.8 million in 2019 and is expected to grow at an anticipated CAGR of 3.3% over the forecast period. The strong presence and substantial growth in the furniture industry in Europe is driving demand for resorcinol used in wood adhesives in the country. The region is characterized by the presence of strict laws and regulations about the usage and disposal of the chemical. Government regulatory agencies, as well as organizations, have carried out research about the health and environmental hazards of resorcinol.

North America emerged as the second largest resorcinol market across the globe in 2016. Resorcinol demand across the region has been primarily driven by the presence of developed automotive and building & construction industry. Presence of prominent automobile manufacturer such as Chrysler, Tesla, Ford, Cadillac, etc. in this region and proper infrastructure coupled with high disposable income emerged as the primary driver for resorcinol market across the North America region. The U.S. is the world’s second-biggest automobile producer and accounts for approx.

The U.S. with a market share of more than 84 % by volume emerged as the largest market for resorcinol across the North America region in 2018. The market is likely to witness higher demand over the coming years owing to the presence of developed tire and building & construction industry. In the U.S., resorcinol is mainly utilized in the production of adhesive for wood and tires. Excellent temperature and mechanical resistance of resorcinol emerged as the primary demand driver for increasing product application in wood and tires. Flame retardant property of resorcinol makes it an ideal product for diphosphate ester flame retardant.

Key Companies & Market Share Insights

Manufacturers as well as academic institutions re-trying to develop a manufacturing process that reduces the salt byproducts and also reduces the energy intensity, corrosion, and co-product liabilities. Companies maintain ISO certified manufacturing facilities to provide optimum quality yield and strive to make the production processes more environmentally safe.

The Indian government in the recent past launched an investigation about the imposing of anti-dumping duty measures against resorcinol imports in the country. The measures were taken by complaints filed with the government authorities by the local manufacturing companies. The initiative was taken by the regional government to safeguard the interests of the domestic industry.

Owing to a failure in developing its manufacturing process, Indspec Chemical closed its manufacturing plant in the U.S. Industry participants include Dynea, Sumitomo Chemical, Atul Ltd, Sigma-Aldrich, AminoChem among others.

Resorcinol Market Report Scope

Report Attribute

Details

Market size value in 2020

USD 486.8 Million

Revenue forecast in 2025

USD 580.3 Million

Growth Rate

CAGR of 3.3% from 2019 to 2025

Base year for estimation

2019

Historical data

2014 - 2019

Forecast period

2020 - 2025

Quantitative units

Revenue in USD million and CAGR from 2020 to 2025

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S., Germany, U.K., China, India, Brazil,

Key companies profiled

Kraeber & Co. GmbH, Alfa Aesar, Akrochem Corporation, Jiangsu Zhongdan Group Co., Ltd., Dynea AS, Amino-Chem Co. Ltd., Sumitomo Chemicals Co., Ltd., Atul Ltd.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Resorcinol Market SegmentationThis report forecasts volume and revenue growth at global, regional & country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2014 to 2025. For the purpose of this study, Grand View Research has segmented the global resorcinol market on the basis of application, and region.

-

Application Outlook (Revenue, USD Million; Volume Tons, 2014 - 2025)

-

Rubber products

-

Wood adhesives

-

UV stabilizers

-

Flame retardants

-

Others

-

-

Regional Outlook (Revenue, USD Million; Volume Tons, 2014 - 2025)

-

North America

-

The U.S.

-

-

Europe

-

The U.K.

-

Germany

-

-

Asia Pacific

-

China

-

India

-

Japan

-

-

Central & South America

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global resorcinol market size was estimated at USD 472.7 million in 2019 and is expected to reach USD 486.8 million in 2020.

b. The global resorcinol market is expected to grow at a compound annual growth rate of 3.4% from 2019 to 2025 to reach USD 580.3 million by 2025.

b. The Asia Pacific dominated the resorcinol market with a share of 55.7% in 2019. This is attributable to rapid industrialization in India & China and the positive growth of the automotive sector in the region.

b. Some key players operating in the resorcinol market include Kraeber & Co. GmbH, Alfa Aesar, Akrochem Corporation, Jiangsu Zhongdan Group Co., Ltd., Dynea AS, Amino-Chem Co. Ltd., Sumitomo Chemicals Co., Ltd., Atul Ltd.

b. Key factors that are driving the resorcinol market growth include increasing product demand for rubber applications and growing use of resorcinol derivatives for manufacturing UV stabilizers.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."