- Home

- »

- Market Trend Reports

- »

-

U.S. Metal Powder Prospective Buyer Database

Industry Overview

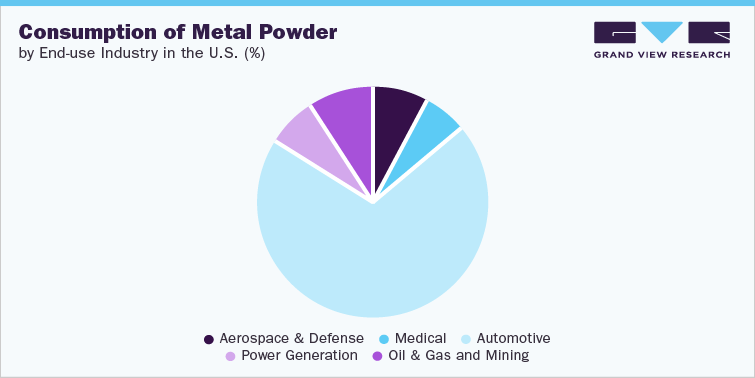

The U.S. metal powder market is growing on account of the increasing adoption of metal powder components in aerospace & defense, automotive, and medical industries. The growing significance of lightweight aircraft parts with complex geometries is propelling market growth.

The process of additive manufacturing relies on computer-aided design (CAD) to create components by building them up layer by layer. This method allows for the production of complex structures without the need for manual labor or machining. Unlike traditional casting processes, expensive molds are not required to create the final products. The high demand for additive manufacturing (AM) in R&D prototypes and new repairing tools for constantly changing parts such as propellers is expected to augment market growth.

Over the past 20 years, metal injection molding has become increasingly important in the manufacturing industry of the U.S. This process involves shaping and sintering metal particles to create complex parts with great precision and in high volumes. The MIM process involves several steps, including preparing the feedstock, injecting it into molds, removing the binder, and finally sintering the metal.

The aerospace & defense segment is an early adopter of additive manufacturing (AM). Companies such as NASA, SpaceX, and other aerospace organizations are benefitting from metal AM technology as it facilitates the production of prototypes with high geometric accuracy in less time and ensures minimal wastage of material. Owing to the aforementioned reasons, several aerospace & defense companies are ordering metal AM printers.

For instance, in September 2022, Rolls–Royce ordered two SLM500 high-volume 3D printers from SLM Solutions. These printers are likely to be utilized to 3D print complex combustor tiles for achieving significant weight and emission reductions, which will eventually help to achieve the world-class performance of the Pearl 10X engine, by increasing overall efficiency by 5%. Thus, increasing investment in metal AM is expected to propel the demand for metal powder over the forecast period.

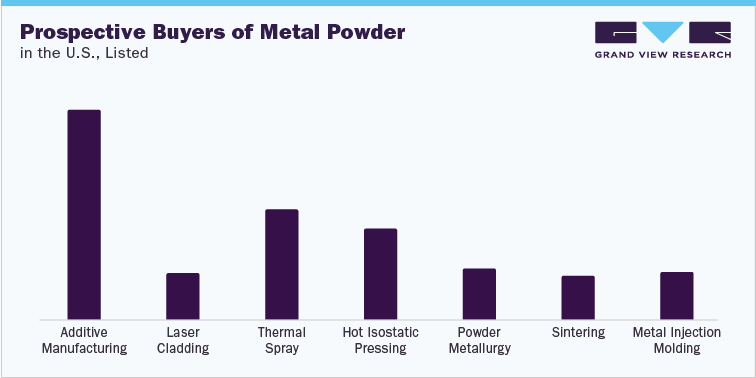

Deliverable Overview

This deliverable includes a database of over 200 potential buyers for metal powder manufacturers in the U.S. The database contains their company names, the type of metal powder they use, whether it is spherical or not, the volume they require, the size range of the powder, the process they use, their address, and their contact information. This database can be used to identify potential customers who are interested in purchasing metal powder, making it easier to target and reach out to potential clients.

Scope Details

Attribute

Details

Total Number of Tabs in the Database

1

Total Number of Companies in the Database

250

Deliverable Format

Excel

Country Scope

U.S.

Application Industries Covered

Additive Manufacturing, Hot Isostatic Pressing, Metal Injection Molding, Sintering, Powder Metallurgy, Thermal Spray, and Laser Cladding

Share this report with your colleague or friend.

GET A FREE SAMPLE

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities.

Contact us now to get our best pricing.

![esomar icon]()

ESOMAR certified & member

![ISO]()

ISO Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

Client Testimonials

"The quality of research they have done for us has been excellent..."

ISO Certified