Stainless Steel Forgings: Providing Lightweight And Strength

Stainless steel forgings form an important component of the machinery or application in which they are used. The forging industry majorly comprises of two components such as forging and casting. The major product types manufactured under stainless steel forgings are cold/hot forged parts, castings and sintered parts.

Cold forged products are manufactured by either by truly closed die forging or impression die forging with circular dies and lubricant at ambient temperature. The major advantage of this method is the material reduction that is achieved by obtaining accurate shapes that result in a reduction in machining costs. Stainless steel forgings provide major advantages in terms of reduced strength and high physical and chemical resistance.

The stainless steel forging industry comprises of a key link between critical manufacturing segments, i.e. metal suppliers and end-user industries. The industry faces a number of challenges and needs to adapt rapidly to match with the substitutes demand. With increasingly more competitive pressure on manufacturers in traditional markets, such as mass product and commodities markets, companies are adapting to highly advanced forging technologies to gain a competitive edge in the market.

Stainless steel castings are expected to be the high demand product in the future. Stainless steel castings are majorly used in environments where the quality requirements are high because the components are used in environments that are hostile, subjected to a large difference in temperature, or they are required to be especially light and strong. The robust properties and freedom of design of stainless steel have helped the construction sector to a large extent. The rising infrastructure investment in developing countries is expected to boost the demand of stainless steel forgings over the forecast period.

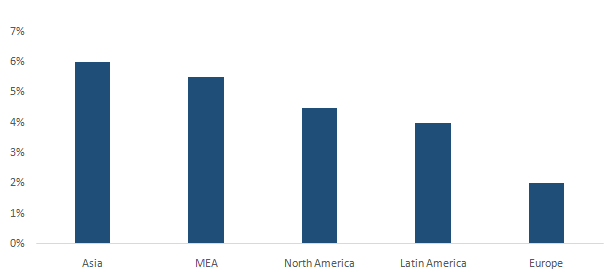

Construction Industry regional growth, 2015, (%)

Stainless steel forgings market is moderately competitive in nature. Companies such as ISGEC Heavy Engineering and Scot Forge have been operating in the stainless steel forgings market for a long period owing to which the market experience is high for these companies. The major observation for the market is the extent to which the market presence of the companies has expanded. The industry participants in the market have majorly practiced localized presence as the number of parts is large and capital requirements for the industry are a major constraint.

Companies such as Canada Forgings and Ecosteel have their operational presence in their respective countries and neighboring countries but lack inter-continental presence. The presence of a large number of local players is also increasing competition in the market. The macroeconomic factors such as oil and gas prices and political situations have a profound effect on the competitive environment of the stainless steel forgings industry.

Stainless steel forgings have yet to gain prominence in the metal forgings market. These products are expected to be the products for the future as they provide major advantages over traditional forged products. The major threat to the market is the rising popularity of aluminum forgings and plastic forgings. The low economies of scale in the manufacturing of aluminum and plastic forgings are the major factor can boost the demand for stainless steel forgings.

In-depth report on global stainless steel forgings market by Grand View Research:

In-depth report on global stainless steel forgings market by Grand View Research:

https://www.grandviewresearch.com/industry-analysis/stainless-steel-forgings-market