- Home

- »

- Paints, Coatings & Printing Inks

- »

-

Global Antifouling Coating Market Size, Share, Industry Report, 2022GVR Report cover

![Antifouling Coating Market Size, Share & Trends Report]()

Antifouling Coating Market Size, Share & Trends Analysis Report By Application (Shipping Vessels, Drilling Rigs & Production Platforms), By Region, And Segment Forecasts, 2016 - 2022

- Report ID: 978-1-68038-727-8

- Number of Pages: 160

- Format: Electronic (PDF)

- Historical Range: 2012 - 2014

- Industry: Bulk Chemicals

Industry Insights

The global antifouling coating market size was USD 1.63 billion in 2015 and is expected to witness considerable growth during the forecast period. Increasing demand in hulls and underwater surfaces of shipping vessels as it provides smoothness and the superior polishing effect is anticipated to drive the growth.

Antifouling coatings are specialized paints, applied to the hull of a ship to prevent the growth of sub-aquatic organisms to improve vessel performance and durability. Increasing consumption in commercial vessels, passenger ships, yachts, cargo, Floating Production Storage, and Offloading (FPSO), and conventional offshore drilling rigs is expected to further augment market growth.

Rising popularity of condition-based monitoring over breakdown maintenance in the shipping sector is expected to play a crucial role in increasing importance of the product. Also, its superior properties including protection against fouling, corrosion, and external contamination is anticipated to propel growth.

Rising demand for FPSO vessels in the upstream oil and gas industry in light of the increasing application of integrated compact systems in deepwater offshore reserves during extreme weather conditions will stimulate market growth. Moreover, rising production of alternative sources, including shale gas and tight oil in the U.S. is expected to increase the application of FPSO, which in turn will spur antifouling coating market expansion in the near future.

The high penetration of coatings manufacturers in the marine sector is expected to hinder the entry of new players. However, high manufacturing cost associated with the incorporation of coating technology is expected to restrain growth over the forecast period.

The emergence of e-commerce platforms has forced antifouling manufacturers and distributors to supply their products through web portals. As a result, companies such as Alibaba and Made-In-China are expected to play a crucial role in providing access to antifouling coating products to buyers.

Buyers located in shipping and offshore oil and gas sectors are likely to procure antifouling coatings through annual supply agreements to get products at discounted prices. Moreover, the rising importance of material management in the manufacturing sector is expected to force buyers to use antifouling coatings in corrosion protection, which will reduce their inventory cost.

High demand from emerging economies such as Vietnam, Philippines, India, South Korea, Saudi Arabia, and Mexico among a few other countries is expected to augment the growth of the antifouling coatings market. Growing shipbuilding activities are anticipated to further drive the product demand from these countries.

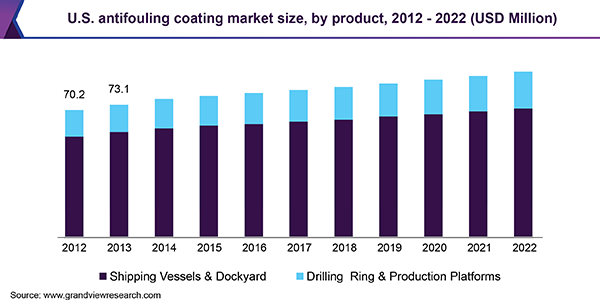

Application Insights

Antifouling coatings were majorly used in shipping vessels, accounting for over 80% of global volume in 2015. The use of these paints induces extension of the dry-docking interval and provides direct fuel saving by keeping hulls free from fouling organisms.

Drilling rigs and production platforms are expected to witness a CAGR of 8.0% in terms of revenue, from 2016 to 2022. Rising capital expenditure for FPSO vessels by companies operating in the upstream oil and gas sector is expected to fuel the demand for antifouling coatings in the near future.

Regional Insights

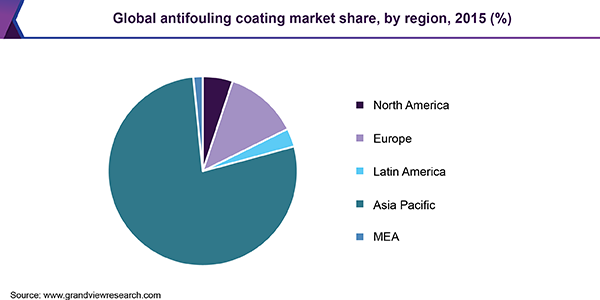

Asia-Pacific was the largest antifouling coatings market, accounting for over 85% of the global volume in 2015. Shipbuilding activities are robust in South Korea, China, Japan, Taiwan, and Philippines. This is expected to result in the dominance of Asia Pacific within the shipbuilding sector, thereby driving demand for antifouling paints. Moreover, increasing expenditure on exploration and production of crude oil and natural gas in China, India, and Thailand are expected to further fuel demand for these paints in drilling rigs and production platforms.

China, South Korea, Taiwan, and Philippines are expected to witness significant growth owing to the presence of a large number of shipbuilding manufacturers. Also, the emergence of Australasia and India as manufacturing destinations of shipping vessels owing to regulatory support for promoting new investments at the domestic level is expected to increase industry size. The presence of stringent regulations by the Environment Protection Agency (EPA) and the European Commission monitoring the use of biocides in personal care, marine, agriculture, and water treatment applications is expected to reduce the demand for antifouling coatings over the forecast period.

The Government of India proposed the Draft National Chemical Policy in September 2013, to elevate the country’s domestic output in the global chemical industry from 3% in 2015 to 6% by 2020. Favorable government policies along with positive outlook towards the shipping sector in India is expected to open new opportunities over the forecast period. In Europe, the market exceeded 197.8 kilotons in 2015. High penetration of yachts manufacturers in Italy and U.K. is expected to have a positive impact on regional growth.

Middle East and Africa market was valued at USD 23.4 million in 2015. Rising capital expenditure for the development of offshore vessels in Saudi Arabia, Nigeria, and Angola is expected to increase the regional use of the product over the forecast period.

Antifouling Coating Market Share Insights

Key players include AkzoNobel, PPG Industries, Sherwin-Williams, Advance Marine Coating, Jotun, Hempel, Kansai Paint, and Nippon Paint. In August 2015, Jotun opened a new production facility for marine coatings at Rio de Janeiro, Brazil with an investment of USD 24.4 million. The manufacturing unit will produce 10 million liters of marine coating products, including antifouling products.

In December 2014, Hempel launched two products under the brand name, GLOBIC, and DYNAMIC, for dry dockings and new shipyard buildings in order to deliver fuel savings of up to 3%. New product development is expected to remain a critical success factor for the market in the near future.

Ongoing R&D to develop coatings from natural materials including palm oil is expected to create immense market potential in the near future. In July 2011, Biomimetics-Innovation-Centre (B-I-C) developed a new non-toxic antifouling coating based on palm seed.

Report Scope

Attribute

Details

Base year for estimation

2015

Actual estimates/Historical data

2012 - 2014

Forecast period

2016 - 2022

Market representation

Revenue in USD Million & CAGR from 2016 to 2022

Regional scope

North America, Europe, Asia Pacific, Central & South America, Middle East & Africa

Report coverage

Revenue forecast, competitive landscape, growth factors and trends

Country Scope

U.S., Germany, China, Brazil

15% free customization scope (equivalent to 5 analyst working days)

If you need specific information, which is not currently within the scope of the report, we will provide it to you as a part of customization

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."