- Home

- »

- Advanced Interior Materials

- »

-

Global 3D Printing Metal Market Size & Trends Report, 2030GVR Report cover

![3D Printing Metal Market Size, Share & Trends Report]()

3D Printing Metal Market Size, Share & Trends Analysis Report By Product (Titanium, Nickel), By Form (Filament, Powder), By Application (Aerospace & Defense, Medical & Dental), By Region, And Segment Forecasts, 2023 - 2030

- Report ID: GVR-1-68038-848-0

- Number of Pages: 120

- Format: Electronic (PDF)

- Historical Range: 2018 - 2021

- Industry: Advanced Materials

Report Overview

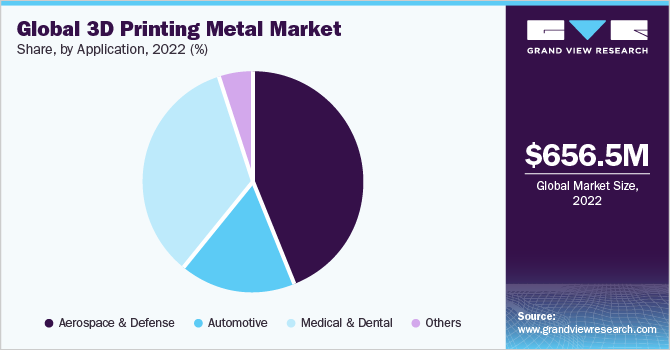

The global 3D printing metal market size was valued at USD 656.5 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 21.1% from 2023 to 2030. Rising investments in 3D printing companies are projected to support market growth over the coming years. For instance, Mantle Inc. has raised USD 25 million in funding for the installation of commercial 3D printing systems in 2022. Mantle, Inc. is a 3D component manufacturer and has already produced over 1 million parts for applications, such as medical devices, deodorant packaging, and dishwasher components. As per the company, its TrueShape 3D printing technology has improved leas times and achieved cost reductions by around 65% during production.

3D printing technology also known as Additive Manufacturing (AM) is used to produce patient-suitable dental products, such as partial dentures, crowns, and bridges in the dental industry. Most of the time, the traditional method of manufacturing is not suitable for low-volume manufacturing as the equipment varies in size, which is now addressed by AM technology, and this is expected to drive the market growth in the U.S.

Manufacturers generally adopt AM to produce scalpel handles, clamps, forceps, hemostats, and prosthetic limbs. Several companies are adopting AM processes for healthcare applications. For instance, 3D Systems Healthcare is expected to collaborate with the medical industry to drive the growth of additive manufacturing in the medical and dental industry.

The shift from rapid prototyping to production using 3D printing is projected to offer new opportunities for market players. As per the recent survey of 3D hubs, over 50% of companies revealed the use of 3D printing for the manufacturing of functional end-use parts. Industries, such as automotive, transportation, and biotechnology, have witnessed increasing usage of 3D printing in the recent past.

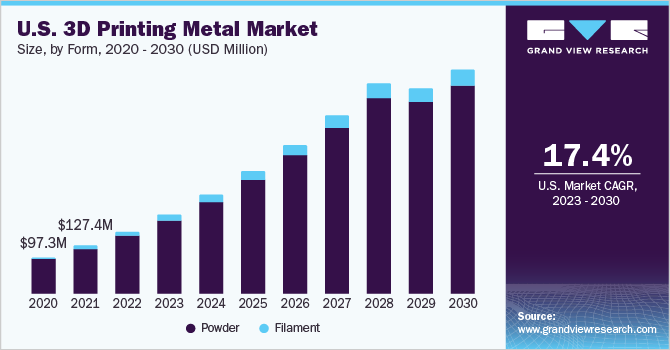

Form Insights

The powder form segment accounted for the largest revenue share of more than 94.0% in 2022 of the global market. Metal powder particles have a number of prominent parameters that not only impact the additive build process but also affect the properties of the finished component. This includes the physical as well as chemical properties of the raw material, which have to be properly known and characterized. This is likely to push the demand for metal powder over the coming years. The spherical metal particles that are used in the 3D printing process must be small, typically in the range of up to 15 to 75 microns, to get a fine print of the finished product.

However, the distribution of the particle must not be skewed but should be evenly spread to obtain an optimal build. Filaments are typically a mix of metal and polymer, wherein the metal is coated with a layer of polymer including PLA and ABS. The producers are working on R&D to develop cost-effective technologies for printing with filament in comparison with the selective laser melting process. This is anticipated to push the demand for filaments over the forecast period.

Product Insights

The titanium product segment accounted for the highest revenue share of over 43% in 2022 and is anticipated to expand at the fastest CAGR over the forecast period. Increasing demand for titanium-based products in various industries due to their properties, such as non-corrosive and high resistance against harsh environments, is expected to fuel the segment growth. The compatibility of traditional polymer 3D printers to print semi-metal equipment when combined with polymers and in the form of filament is further expected to drive market growth.

The ability of the aerospace & defense industry to bear high initial costs and adapt to new technologies is anticipated to propel the development of titanium powder for 3D printing applications. An innovative aerospace approach aided by the necessity of complex geometric structures is expected to drive the 3D printing technology, thereby boosting the demand for titanium powder.

Stainless steel is projected to have significant demand over the coming years owing to its high potential in various industries as it has low carbon and high chromium content. Parts printed using stainless steel are lightweight, strong, and durable. Moreover, stainless steel helps in printing large objects with a high-quality surface finish.

Application Insights

Aerospace and defense accounted for the largest volume share of over 40% in 2022. The ability to manufacture complex components in less time is forcing aerospace & defense players to invest in 3D printing. For instance, in 2021, Senvol, an 3D printing data specialist received a new round of funding from the U.S. Department of Defense to optimize aerospace and defense components.

The medical and dental application segment is expected to register the fastest growth rate of 22.3% in terms of revenue, across the forecast period. 3D printing is used to produce prosthetic limbs, implants, forceps, and hemostats in the medical industry. Many medical companies are adopting 3D printing processes for various medical applications. For instance, Monogram is developing orthopedic implants through 3D printing. Similarly, Open Bionics has developed low-cost robotic prosthetics with the help of 3D printing.

Automotive is another key application segment in 3D printing metal market. The introduction of 3D printing metal technology in the automotive industry is expected to display many benefits such as producing hollow components, comparatively thinner walls, and mixing various raw materials while manufacturing a component. This is projected to create a positive impact on the development of the market growth over the coming years.

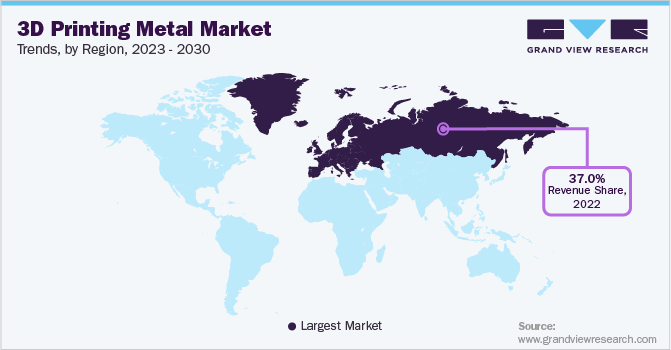

Regional Insights

Based on region, Europe is projected to register the fastest CAGR of 22.4% from 2023 to 2030, in terms of revenue. The U.K., Germany, France, the Netherlands, Spain, and Italy lead the regional market in terms of the adoption of 3D printing for end parts, particularly in the healthcare and aerospace sectors. Some of the countries have developed a national strategy for additive manufacturing as a part of their Industry 4.0 and advanced manufacturing strategies.

Major companies that currently use 3D printing in the U.K. are Attenborough Dental and Renishaw for crowns and bridges; Bowman International for bearing cages; and GKN for automotive and aerospace components. However, a vast majority of the U.K. industry has yet to fully adopt the metal additive manufacturing technology, thereby denoting significant potential for market growth.

The growing adoption of 3D printing by aerospace companies in Asia Pacific is projected to drive the regional market. In the aerospace sector, the major aircraft manufacturer in India, Hindustan Aeronautics Ltd. (HAL), is using the metal AM technology to manufacture various components for its indigenous engine program. For instance, HAL is adopting the Direct Metal Laser Sintering (DMLS) technique to produce components for its Hindustan Turbofan Engine-25 (HTFE-25).

Key Companies & Market Share Insights

The global market is currently in the growth stage and holds huge potential owing to its rising penetration and adoption across different industries. The market is also witnessing rising investments from small companies. With the rising competition, merger & acquisition activities in the market are likely to increase over the forecast period. For instance, in 2019, Aerojet Rocketdyne Holdings, Inc. acquired 3D Materials Technology, Inc. (3DMT), an additive manufacturing solution provider. The acquisition of 3DMT is projected to benefit the company in expanding its products & services offerings in the aerospace & defense industry. Some of the prominent players in the global 3D printing metal market include:

-

Arcam AB

-

ExOne GmbH

-

Carpenter Technology Corp.

-

Renishaw PLC

-

Materialise NV

-

3D Systems Corp.

-

Voxeljet AG

-

Sandvik AB

-

Hoganas AB

-

GKN PLC

3D Printing Metal Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 845.8 million

Revenue forecast in 2030

USD 3,037.8 million

Growth Rate

CAGR of 21.1% from 2023 to 2030

Market size volume in 2023

5,304.6 tons

Volume forecast in 2030

20,540.3 tons

Growth Rate

CAGR of 22.4 % from 2023 to 2030

Base year for estimation

2022

Historical data

2018 - 2021

Forecast period

2023 - 2030

Quantitative Units

Volume in Tons, Revenue in USD million, and CAGR from 2023 to 2030

Report coverage

Volume forecast, revenue forecast, competitive landscape, growth factors, and trends

Segments covered

Form, product, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South Africa; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; U.K.; France; Spain; Italy; China; India; Japan; Singapore; South Korea; Brazil

Key companies profiled

Arcam AB; ExOne GmbH; Carpenter Technology Corp.; Renishaw PLC; Materialise NV; 3D Systems Corp.; Voxeljet AG; Sandvik AB; Hoganas AB; GKN PLC

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

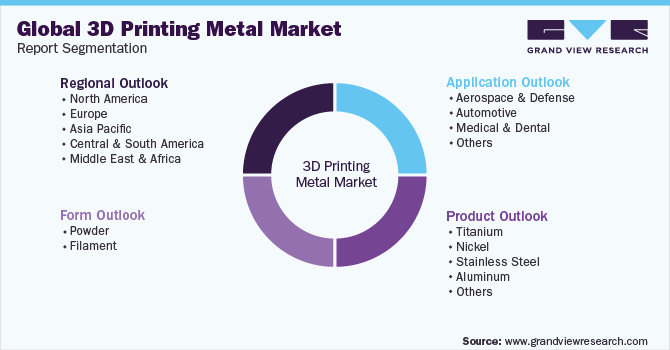

Global 3D Printing Metal Market Report Segmentation

This report forecasts revenue and volume growth at global, regional and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the global 3D printing metal market report on the basis of form, product, application, and region.

-

Form Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Powder

-

Filament

-

-

Product Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Titanium

-

Nickel

-

Stainless Steel

-

Aluminum

-

Others

-

-

Application Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Aerospace & Defense

-

Automotive

-

Medical & Dental

-

Others

-

-

Regional Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

U.K.

-

France

-

Spain

-

Italy

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Singapore

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global 3D printing metal market size was estimated at USD 656.5 million in 2022 and is expected to reach USD 845.8 million in 2023.

b. The global 3D printing metal market is expected to grow at a compound annual growth rate of 21.1% from 2023 to 2033 to reach USD 3,037.8 million by 2030.

b. Based on application segment, aerospace & defense held the largest revenue share of more than 43% in 2022 owing to rising use of 3D printing for prototyping and low volume production of complex parts in aerospace industry.

b. The key players operating in the 3D printing metal market include Arcam AB, ExOne GmbH, 3D Systems Corporation, Materialise NV, Renishaw PLC, Hoganas AB, Voxeljet AG, Carpenter Technology Corporation, Equispheres, GKN PLC, and Sandvik AB.

b. Key factors that are driving the 3D printing metal market are cost-effectiveness, reduced lead time, and ability to produce complex parts.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."