- Home

- »

- Plastics, Polymers & Resins

- »

-

Plastic Resin Market Size, Share And Trends Report, 2030GVR Report cover

![Plastic Resin Market Size, Share & Trends Report]()

Plastic Resin Market Size, Share & Trends Analysis Report By Product (Crystalline Resin, Non-crystalline Resin, Engineering Plastic), By Application (Packaging, Automotive, Construction), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-3-68038-877-0

- Number of Report Pages: 125

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Bulk Chemicals

Plastic Resin Market Size & Trends

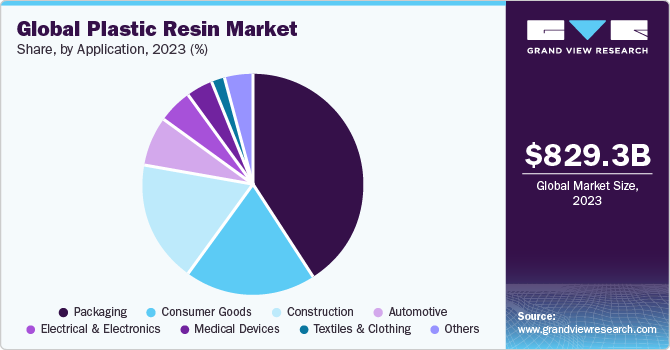

The global plastic resin market size was valued at USD 829.26 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030. Rising product demand from the construction, automotive, and electrical and electronics industries is driving market expansion. The rapidly growing global automotive sector is predicted to drive product demand in applications such as under-the-hood components, automobile exteriors, and interiors. The demand for lightweight and economical multi-utility vehicle models with high fuel efficiency and an emphasis on aesthetics and comfort is driving the increased use of resins in the automobile industry.

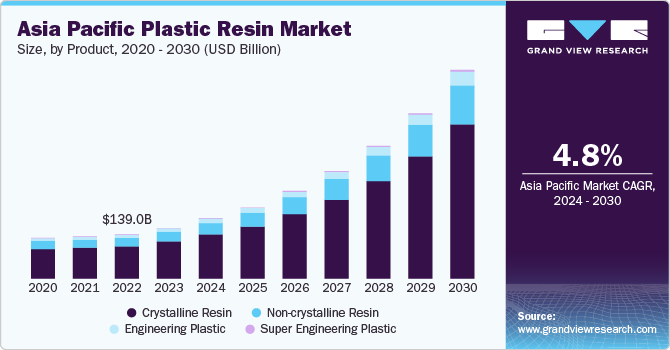

Asia Pacific plastic resins market is characterized by various manufacturing industry, as a result of the increased emphasis on research and development, combined with favorable government initiatives to attract investments, is likely to result in regional market expansion. China is self-sufficient in plastic production, with an appropriate number of factories and production capacity to meet domestic demand. Furthermore, because of its enormous manufacturing base, China exports a variety of plastics to neighboring countries.

Moreover, over the years, the market has grown rapidly, fueled by diverse industries including as packaging, automotive, construction, electronics, and consumer products. Increased income levels contribute to increased purchase of consumer products, which is predicted to raise demand for plastic resins in China.

Furthermore, China is a significant producer of electronics such as laptop computers, television sets, and smartphones. The significant shift in customer preference for electronics for daily activities is boosting the industry in this region even further. Government policies and incentives promoting the plastics industry, such as investments in infrastructure and technological development, are likely to impact market growth.

Market Concentration & Characteristics

Market growth stage is high, and pace of the market growth is accelerating. The plastic resins market is characterized by a high degree of innovation owing to the rapid technological advancements driven by factors such as advancements in the production of plastic resins, the availability of raw materials, and increasing plastic resins consumptions across several applications including packaging, building & construction, automotive, among others. Subsequently, innovative plastic resins applications are constantly emerging, disrupting existing industries and creating new ones.

The market is also characterized by a high level of merger and acquisition (M&A) activity by the leading players. This is due to several factors, including the desire to gain access to new production technologies and talent, need to consolidate in a rapidly growing market, and increasing strategic initiatives of plastic resins.

The plastic resins industry is also subject to increasing regulatory scrutiny. The global market is subject to numerous regulations, guidelines, and restrictions regarding plastic production and its applications owing to the toxic nature of raw materials such as crude oil, coupled with certain health hazards of improperly disposed products and over-exposure to chemicals contained in these resins.

There are a limited number of direct product substitutes for plastic resins. However, there are a number of technologies that can be used to achieve sustainable outcomes to polymer foam, such as Natural and Bio-based Foams, Fiberglass. These substitutes can be used certain applications, but they typically do not offer the same level of performance or flexibility as polymer foam

End-user concentration is a significant factor in the market. Since there are a number of end-user industries that are driving demand for post-consumer recycled plastics. The concentration of demand in a small number of end-user industries creates opportunities for companies that focus on developing polymer foamsolutions for the consumer electronic industry. However, it also creates challenges for companies that are trying to compete in a crowded market.

Product Insights

Crystalline resin sector dominated the market and accounted for a share of 54.9% in 2023. Owing to their qualities, crystalline resins are projected to see a surge in demand. They thrive in situations involving wear, bearings, and structural loads. Crystalline resins are widely utilized in packaging because to their durability and barrier qualities, owing to the increasing e-commerce sector and consumer products packaging.

Crystalline resins have a high melting point, rigid surface, and are not affected by the penetration of solvents. Their crystallinity makes them strong while reducing their impact resistance. There are broadly three type of resins: epoxy resins, polyethylene and polypropylene. Polyvinyl chloride is one of the most widely used thermoplastic polymers globally. Without the addition of plasticizers, PVC is extremely brittle. It is used in specific construction activities, clothing fibers, and healthcare industry. In construction industry, PVC is used for insulation around electrical wires and in particular flooring applications as an alternative to rubber.

Application Insights

The packaging segment dominated the market in 2023The expanding packaging business, fueled by rising demand for packaged foods and beverages, will drive category expansion. Furthermore, several government agencies have established severe criteria for the safe use of plastic materials in food and beverage applications, which is expected to promote segment expansion.

The automotive application is projected to grow at fastest CAGR over the forecast period supported by an increase in the use of plastics in automotive components, as well as an increase in the production of passenger cars and heavy-duty vehicles, particularly in Asia Pacific and Central & South America. Plastic resins provide more design flexibility, allowing for the fabrication of sophisticated parts and components that can be modified to fit specific automobile specifications.

Medical application segment is also anticipated to witness substantial upsurge in adoption of plastic resins.Resins are commonly used in the production of medical devices because they provide improved clarity, cost-effectiveness, and biocompatibility. To attain suitable qualities for application in medical devices, several polymers such as Polyethylene (PE) and Polystyrene (PS) are combined. Plastic resins are often more cost-effective than alternative materials, aiding in the production of affordable medical devices and equipment.

Regional Insights

China dominated the market and accounted for a 40.24% share in 2023. This is due to causes such as fast urbanization, increased construction activity, and rising consumer goods and packaging demand in the region. China is a global manufacturing powerhouse, fueling high demand for plastic resins in sectors such as automotive, electronics, packaging, and construction. Furthermore, demand for polyethylene terephthalate (PET) plastic bottles for the packaging of bottled water, juices, soft drinks, medications, household cleaners, and personal care goods is a major element driving the growth of the market.

Europe is anticipated to witness significant growth in the plastic resins industry. The European market is characterized by stringent environmental rules imposed by regulatory authorities such as the European Chemicals Agency (ECHA) and the European Commission. Many European countries, including Denmark, France, Germany, and Austria, have had landfill prohibitions in place for decades. High landfill tipping fees, dumping taxes, waste management, and landfill closure expenses have spurred Europeans to move to recycled products. Zero Waste Europe, a waste-reduction group working in partnership with the European Commission, aims to reduce residual waste to zero.

Key Companies & Market Share Insights

Some of the key players operating in the market include BASF SE and Arkema Group

-

BASF SE is engaged in the production of a broad range of plastic products such as performance polymers, plastic additives, and polyamides & intermediates, which find use in automotive & transportation, construction, electrical & electronics, and consumer goods industries. It offers post-consumer recycled resins through its plastics & rubber segment.

-

SABIC operates through five business segments: culture of continuous improvement, petrochemicals, specialties, agri-nutrients, and metals. The products manufactured under these segments cater to agriculture, building & construction, automotive, consumer goods, electrical & electronics, healthcare, and packaging industries.

Formosa Plastics Corporation and Evonik Industries AG are some of the emerging market participants in the plastic resins market.

-

Formosa Plastics Corporation is engaged in the manufacturing of plastic resins and intermediates for plastics. The company has segmented its products into three business divisions including plastic materials, petrochemical, and fiber. It serves the end-use industries including packaging, automotive, utility, consumer goods, construction, electrical & electronics.

-

Evonik Industries AG operates through three business segments, namely, nutrition & care, performance materials, and resource efficiency, and caters to various end-use industries including adhesives & sealants, agriculture, automotive, composites, construction, food, pharmaceuticals, energy, paints & coatings, and tire & rubber.

Key Plastic Resin Companies:

- BASF SE

- SABIC

- Dow

- DuPont

- Evonik Industries AG

- Sumitomo Chemical Co., Ltd.

- Celanese Corporation

- Eastman Chemical Company

- Chevron Phillips Chemical Co., LLC

- LOTTE Chemical Corporation

- Exxon Mobil Corporation

- Formosa Plastics Corporation

- TORAY INDUSTRIES, INC.

- MITSUI & CO. LTD

- TEIJIN LIMITED

- LG Chem

- Avient Corporation

Recent Developments

-

In December 2023, LyondellBasell introduced a new recycled resin derived from discarded maritime plastics. The new resin is the result of a partnership between an unnamed 'renowned' German original equipment manufacturer and a plastic mechanical recycler.The PP copolymer recyclate, known as CirculenRecover PPC TRC 2179N, can be used in injection moulding for automotive applications, a first in the industry. While some car components are already made from recycled ocean plastics in the automobile sector,

-

In September 2023, Delrin introduced a high molecular weight nucleated resin designed specifically for use in situations demanding exceptional creep resistance and fatigue durability. Delrin 51HSE expands Delrin's capacity to substitute metal, allowing customers to save money and weight while lowering noise. It also permits smart design principles that are advantageous for lowering carbon footprints.

-

In January 2023, SABIC introduced a new ULTEM resin grade that it claims will aid designers in the styling and aesthetics of consumer electronics components. In addition, the company claims that the resin saves about 25% of the cost of metal. This polyetherimide (PEI) material has surface hardness to help eliminate scratches and high modulus to help avoid PVD layer cracks, which further improves its appearance.

Plastic Resin Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 996.52 billion

Revenue forecast in 2030

USD 1.07 trillion

Growth rate

CAGR of 4.5% from 2024 to 2030

Base year for estimation

2023

Historical data

2018 - 2022

Forecast period

2024 - 2030

Report updated

January 2024

Quantitative units

Volume in kilotons, revenue in USD million, and CAGR from 2024 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, Application, and Region

Regional scope

North America, Europe, China, Asia, Pacific, Central & South America, Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; UK; France; Italy; Poland, Spain, India, Japan, Thailand, Malaysia, Indonesia, Vietnam, Singapore, Philippines, Brazil, Argentina, Saudi Arabia; UAE; Oman

Key companies profiled

BASF SE; Dow, Inc.; SABIC; Evonik Industries AG; Sumitomo Chemical; Arkema; Celanese Corp.; Eastman Chemical Company; Chevron Phillips Chemical Co., LLC; Lotte Chemical Corp.; Covestro AG; Toray Industries, Inc.; Teijin Ltd.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Plastic Resin Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global plastic resin market report based on product, application, and region:

-

Product Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Crystalline Resin

-

Epoxy

-

Polyethylene

-

Polypropylene

-

-

Non-crystalline Resin

-

Polyvinyl Chloride (PVC)

-

Polystyrene (PS)

-

Acrylonitrile Butadiene Styrene (ABS)

-

Polymethyl Methacrylate (PMMA)

-

-

Engineering Plastic

-

Nylon

-

Polybutylene Terephthalate (PBT)

-

Polycarbonate (PC)

-

Polyamide

-

-

Super Engineering Plastic

-

Polyphenylene Sulfide (PPS)

-

Polyether Ether Ketone (PEEK)

-

Liquid Crystal Polymer (LCP)

-

-

-

Application Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Packaging

-

Food

-

Beverage

-

Medical

-

Retail

-

Others

-

-

Automotive

-

Construction

-

Electrical & Electronics

-

OA Equipment & Home Appliances

-

Electronic Materials

-

Others

-

-

Logistics

-

Consumer Goods

-

Textiles & Clothing

-

Clothing

-

Industrial use

-

Others

-

-

Furniture & Bedding

-

Agriculture

-

Medical Devices

-

Others

-

-

Regional Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

U.K.

-

France

-

Italy

-

Poland

-

Spain

-

-

China

-

Asia

-

India

-

Japan

-

Thailand

-

Malaysia

-

Indonesia

-

Vietnam

-

Singapore

-

Philippines

-

-

Pacific

-

Central & South America (MEA)

-

Brazil

-

Argentina

-

-

Middle East and Africa (MEA)

-

Saudi Arabia

-

UAE

-

Oman

-

-

Frequently Asked Questions About This Report

b. The global plastic resin market size was estimated at USD 829.26 billion in 2023 and is expected to reach USD 996.52 billion in 2024.

b. The global plastic resin market is expected to grow at a compound annual growth rate of 4.5% from 2024 to 2030 to reach USD 1.07 trillion by 2030.

b. China dominated the plastic resin market with a share of 40.24% in 2023. This is attributable to the growing packaging industry supported by increasing consumer inclination toward consumption of packaged products, such as food and beverages.

b. Some key players operating in the plastic resin market include BASF SE; SABIC; Dow; DuPont; Evonik Industries AG; Sumitomo Chemical; Celanese Corporation; and Eastman Chemical Company.

b. Key factors that are driving the plastic resin market growth include increasingly utilized for manufacturing medical devices, and its application for the packaging industry.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."