Ballistic Protective Equipment Market - Protecting The Ones Who Protect Us!

Modern world has witnessed a rise in geo-political tension and terrorism, which are some of the gravest threat to humankind. This has resulted into several armed conflicts around the world, such as, Indo-Pak conflict over Kashmir, the Syrian civil war, Yemen crisis, ISIS conflict, and the Lebanon conflict. All these threats are also driving the countries to deploy greater number of armed forces personnel, to gain control over these problems and help maintain law & order situation in these areas. With rise in deployment of armed forces, equipment that are necessary to save their lives have also gone through a series of change, for the better.

Among all the defense kits and gizmos, protective kits, and in them, ballistic protective equipment have higher level of integrity and importance, when it comes to saving lives. Contrary to general belief, ballistic protective equipment is in use since a long time. In ancient times, the materials used for ballistic protection were made from metals and were heavy. Such heavyweight armor also tends to restrain the free body mobility of soldiers during warfare. However, the recent advancements in textiles have enabled manufacturing ballistic PPE with better or equivalent performance than their metallic predecessors. These developments have led the Ballistic Protective Equipment Market to flourish and it is anticipated to reach USD 5.75 billion by 2025, according to a new report by Grand View Research, Inc.

The use of textile materials has numerous benefits such as improved comfort, lower weight, ease of manufacturing for different body sizes, and flexibility of body movement. Ballistic protective clothing is designed based on the level and type of threat to be resisted. Clothing used for ballistic protection can be a heavy and limit body movement to some extent. However, while designing body armor, the finest balance between mobility and stability needs to be maintained.

Microscopic view on armors

Protective armor has undergone a remarkable change from the metals, furs, and skins used in early times to new advanced equipment with improved performance levels. The woven fabrics prepared from silk were used in previous times for designing textiles with ballistic protection features, and those have been lately replaced by advanced fibers such as nylon 6,6 and aramids. These fibers have low elongation and high tensile strength essential for soft body armor.

The modern body armor is classified into hard body armor and soft body armor, depending on the type of material used. The hard armor is heavier to wear, and the protection level of hard armor is more than soft armor. However, it provides lesser flexibility in body movement than soft armor. Military personnel and law enforcement officers might wear hard body armor while encountering high levels of threat to body protection. Soft body armor is chosen as it normally provides adequate protection and mobility.

-

Hard body armor – It is made from rigid materials such as reinforced plastics, composites, ceramics, and metal plates. Standard hard armor is made with multiple layers, commonly including ceramic plates and laminated composite panels. Hard body armor might also add an anti-trauma layer, which will help in reducing the potential injury caused by dynamic deformation of the shield into the wearer’s body.

-

Soft body armor – It has several layers of high-performance materials that are made from ballistic fibers. The most important properties of soft armor are its high strength and low extension, i.e. high modulus. The fibers are formed into advanced woven or other fabrics, which can be sewn to make vests or soft clothing materials.

The rising technological trends have changed the types of threats on the battlefield and other combat environments. With increasing weapon penetration capability, there is a need for innovative body protection devices to be developed in the future. The future ballistic PPE needs to be designed with lightweight, minimized bulk, and also improved thermo-physiological comfort while allowing tactical mobility.

Other factors to be considered while manufacturing body armor are the integration of functionality to achieve multi-role protection with a minimum of layers, survival in extreme conditions, use of environment-friendly chemicals & processes, and minimization of life cycle cost. Recycling and easy disposal of body armor without affecting the environment are also important at the end of its life cycle.

Market Development Areas….

Ballistic protection market has witnessed significant technological innovations, which offers armor wear developed from new advanced materials for law-enforcement professionals. Companies have achieved important improvements with the development of various materials that are used for the production of ballistic protection materials.

-

High-performance fibers - The most recent materials for ballistic protection use yarns of stronger high-performance fibers, such as ultra-high molecular weight polyethylene (UHMWPE), aromatic polyamides, poly-para-phenylene benzobisoxazole, and ballistic nylon, which scatter energy and shift it from the point of impact of a shot across the fabric layers by breaking and stretching.

-

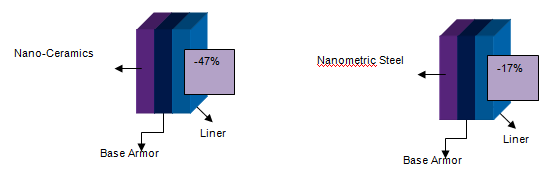

Reducing Weight - The improvement in technologies is aiding the development activities on nanometric steel and nanoceramics, which will reduce the weight of protection kits for developing advanced modular armor protection (AMAP) products. For example, IBD NANOTech company has introduced a protection kit related to STANAG 4569 Level 3 by a weight of 32 kg/m², which is an improvement as associated to a standard kit having a weight of 60 kg/m² with conventional technologies.

Ballistic Protective Equipment Market

Recent developments were focused toward the use of composites consisting of carbon nanotubes, graphene, and other nanomaterials for providing armor having lightweight with enhanced safety from high-velocity projectiles. Also, the technology trends are increasing to integrate additional functions, such as power source and communication tool.

Ballistic Competition

Increasing innovation is the driving force of competition in this market. Major companies like DuPont Company, Honeywell International, Inc., Toyobo Co., and Teijin Twaron, provide raw materials to body armor industries. After procuring raw materials, body armor manufacturers commence production of bulletproof helmets, soft, and hard armors. MKU, 3M Company, BAE Systems Plc, EnGarde, PSP, Inc., and Tencate form the group of major vendors of this industry.

Recent Developments

Innovation in the market churns out several developments that highlights the vitality of the market. Also, along with technological enhancements; mergers and acquisition have potential to mark the path of growth.

-

The U.S. Army is currently working to ensure that all Soldiers have cutting edge equipment and armor that fit comfortably and retains high-level protection under the Soldier Protection System (SPS) program.

-

3M Company has completed the sale of the company’s advanced-ballistic protection business to Avon Rubber p.l.c. for $91 million. The business consists of ballistic helmets, body armor, flat armor, and related helmet-attachment products serving government and law enforcement.

In-depth report on global ballistic protective equipment market by Grand View Research:

In-depth report on global ballistic protective equipment market by Grand View Research:

http://www.grandviewresearch.com/industry-analysis/ballistic-protective-equipment-market

To schedule a free market intelligence database demo, please complete the form below:

Service Guarantee

-

Insured Buying

This report has a service guarantee. We stand by our report quality.

-

Confidentiality

Your transaction & personal information is safe and secure.

-

Custom research service

Design an exclusive study to serve your research needs.

-

24/5 Research support

Get your queries resolved from an industry expert.