U.S. specialty oleochemicals - Growing demand for sustainable and biodegradable products in order to reduce reliance on petrochemicals

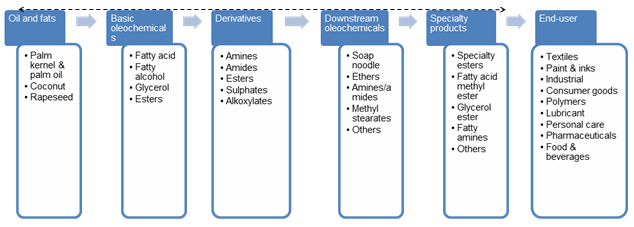

Oleochemicals have numerous commercial applications in textiles, paint & inks, industrial, consumer goods, polymers, lubricant, personal care, pharmaceuticals, food & beverages and many more, owing to its growing demand for sustainable and biodegradable products in order to reduce reliance on petrochemicals.

Large multinational corporations such as Vantage Specialty Chemicals, Emery Oleochemicals, dominate the U.S. oleochemicals market with significant presence across the value chain. The market is characterized by vertical integration across each component of the value chain. The value chain begins with the oil palm plantation, which generally involves independent farmers or plantation companies.

Palm/palm oil are the basic feedstock required to manufacture oleochemicals. Farmers or plantation companies enjoy the maximum profit margins, which lie in the range of 50% to 80% on account of increasing dependability of refiners on these plantation companies.

The cost of switching suppliers is high for refiners as plantation companies have large land dedicated to palm farming and refiners have less chance for shuffling their suppliers. Palm fruit bunches are grown and are further sent for crushing where crude palm oil and crude palm kernel oil is obtained.

Crude palm fruit oil and crude palm kernel oil are then sent to the refinery for their refinement. The refiners enjoy the minimum profit margin (<3%) in the overall value chain. The oils are chemically treated, bleached and refined to make it industrially useful. Fractionation process is undertaken and the oil is separated into olein, stearin, and oil. The liquid component of oil after fractionation is called olein and the slightly solid component is referred to as stearin.

Once through the refinery, the palm oil is then separated into specialty fats and basic oleochemicals. The basic oleochemicals include fatty acids, fatty alcohols, esters and glycerol. These basic chemicals are the building blocks for downstream or second-generation oleochemicals. Using basic specialty chemicals` as raw materials, companies produce downstream products like specialty esters, fatty acid methyl ester, glycerol ester, fatty amines and others.

The main processes for manufacturing oleochemicals include hydrolysis, hydrogenation, and transesterification. The hydrolysis of oils and fats into glycerine and fatty acids is the most basic of oleochemical processes. The vegetable oils and fats undergo a high temperature and pressure hydrolysis process to split fat and oil molecules into fatty acids and glycerine.

In-depth report on U.S. specialty oleochemicals market by Grand View Research:

In-depth report on U.S. specialty oleochemicals market by Grand View Research:

https://www.grandviewresearch.com/industry-analysis/us-specialty-oleochemicals-market

To schedule a free market intelligence database demo, please complete the form below:

Service Guarantee

-

Insured Buying

This report has a service guarantee. We stand by our report quality.

-

Confidentiality

Your transaction & personal information is safe and secure.

-

Custom research service

Design an exclusive study to serve your research needs.

-

24/5 Research support

Get your queries resolved from an industry expert.