- Home

- »

- Paints, Coatings & Printing Inks

- »

-

Coating Equipment Market Size And Analysis Report, 2030GVR Report cover

![Coating Equipment Market Size, Share & Trends Report]()

Coating Equipment Market (2023 - 2030) Size, Share & Trends Analysis Report By Product (Specialty Coating Equipment, Powder Coating Equipment, Liquid Coating Equipment), By Application, By Region, And Segment Forecasts

- Report ID: GVR-1-68038-980-7

- Number of Report Pages: 152

- Format: PDF

- Historical Range: 2017 - 2020

- Forecast Period: 2022 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Report Overview

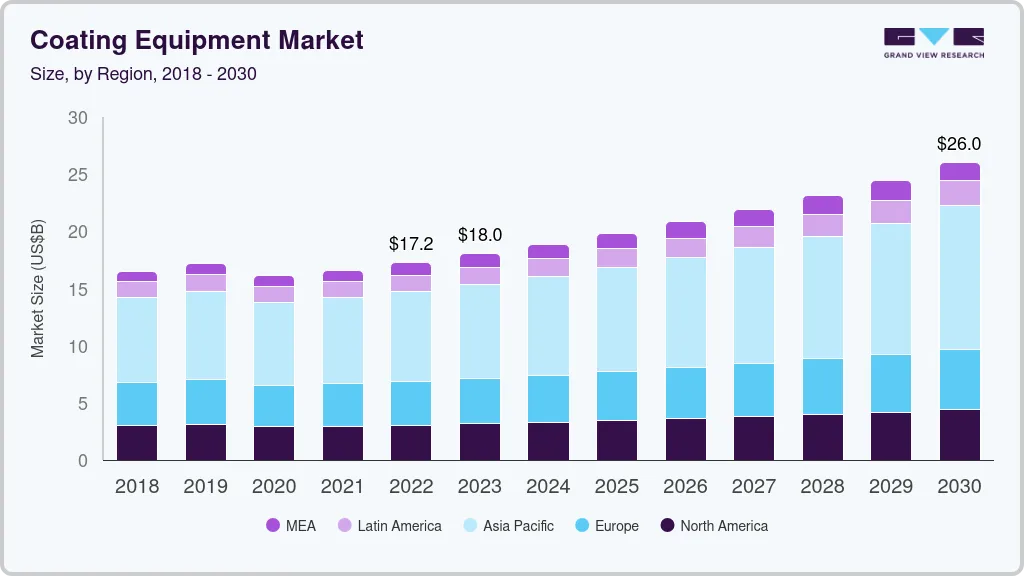

The global coating equipment market size was estimated at USD 17,248.9 million in 2022 and is expected to expand at a compounded annual growth rate (CAGR) of 5.3% from 2023 to 2030. The growing product demand in various applications such as aerospace, automotive, and construction is expected to drive the industry’s growth. The coatings industry endured a serious slump as a result of the impact of the shutdown imposed to stop the spread of the coronavirus. As a result, demand for coatings nearly dropped in many places and was unlikely to be revived until governments relaxed their stringent stay-at-home regulations, allowing their respective economies to return to some sort of stability.

The global coating equipment market is one of the primary industries that would experience supply chain delays and industrial interruptions as a result of COVID-19 regulations. The shutdown of various facilities and industries in key locations is affecting global supply chains and significantly harming production, delivery schedules, and product sales.

One of the primary reasons driving the market is the significant growth in global demand for electric cars. The coating is crucial to avoid rust damage to the surface of electric cars and their goods, as well as contributing to their appearance and quality. As a result, the rising demand for coated electronic devices in electric cars is likely to boost market growth.

Governments are taking numerous initiatives, in accordance with technological advancements, to sell electric-powered vehicles through various subsidies such as incentives for installing charging stations and budget allotment for the improvement of electrical battery generation regarding weather extrude concerns.

The use of high-end coating equipment is not an economical option due to low capacity and less specific applications. The cost of the equipment is a vital factor in choosing both the coating methods and materials. Therefore, the availability of low-cost alternatives such as brushes, and rollers limits the market in some applications and is expected to hamper the market growth during the forecast period.

Product Insights

The powder coating equipment product segment is expected to witness a CAGR of 5.0% from 2022 to 2030 due to its ability to effectively coat products with properties such as de-icing, abrasion, corrosion, and heat resistance which is anticipated to provide positive scope for the industry. The wastage in powder coating is comparatively less which is expected to further drive the market demand

The cost of liquid coating is less compared to other products which is anticipated to provide a positive scope for the industry’s growth over the forecast period. It is anticipated to witness demand from the construction sector due to its high utilization in the painting application.

The specialty coating equipment product segment is expected to witness a CAGR of 5.6% from 2022 to 2030 owing to the increasing utilization of technologies such as physical vapor deposition and chemical vapor deposition across various industries is likely to augment the growth.

The ability of specialty equipment to coat various products including wood, metal, and flooring is expected to propel the market growth. In addition, the product is expected to substitute powder coating equipment on account of its capability to operate on metals.

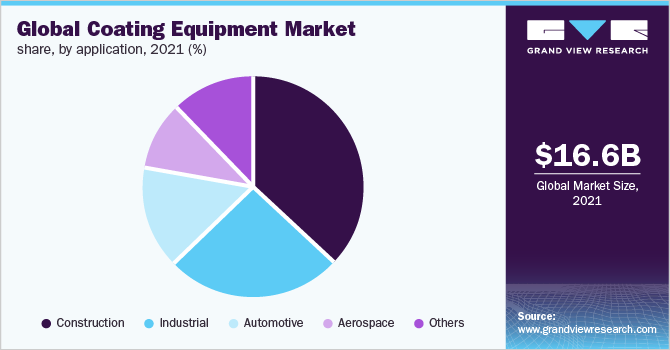

Application Insights

Automotive application is expected to witness a CAGR of 6.5% over the forecast period. Penetration of equipment in the automotive application is expected to be high over the forecast period due to the increasing utilization of technologies like vacuum deposition coating, and physical vapor deposition to obtain thin film coatings across the industry.

Increasing demand for coated electronic devices and focus on the protection of car exteriors is expected to drive the product demand in the coming years. Automated equipment is considered to lower the amount of wastage during automotive production which is likely to provide a positive scope for market growth.

Growing purchasing power, high living standards, and rapid urbanization are expected to drive the construction sector worldwide. This is likely to develop new opportunities for the coating equipment industry over the coming years. Powder coatings are being increasingly used in aluminum extrusions of windows, bathrooms, and electrical fixtures, thereby fueling the demand.

Other applications including agriculture and oil & gas industries are expected to witness considerable growth of 5.1% over the forecast period due to increasing consumption of food and energy. The oil & gas industry utilizes the product to coat the drilling equipment which is anticipated to provide a positive scope for market growth.

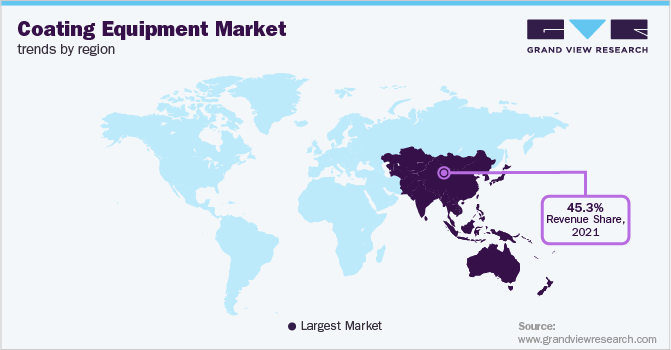

Regional Insights

The Asia Pacific region led the market in 2021, accounting for a share of 45.3% owing to the growing construction sector, industrial development, high population growth, increase in demand for automobiles, and growing demand for coatings with better efficiency in this region is anticipated to be the key factor for product demand over the forecast period.

Efficiency improvements in existing buildings and renovations in the Europe region have the highest potential to stimulate demand for coatings. Moreover, the planning of various PPP projects in the region for the construction of roads, hospitals, schools, and airports is expected to boost the market demand over the forecast period.

The U.S. dominated the North America coating equipment industry accounting for a share of 57.5% in 2021. Increased industrial budget by the U.S. government to create more jobs is expected to drive the manufacturing sector across the region thereby providing positive scope for market growth over the forecast period.

The increasing production of electric vehicles in Europe and the presence of key automotive OEMs such as Volkswagen and BMW AG are anticipated to increase demand for coating equipment. In addition, technical developments in product development to boost productivity and energy savings are anticipated to drive the market.is expected to provide positive scope for market growth over the forecast period.

Key Companies & Market Share Insights

The key players across the industry are involved with manufacturing a completely automated system as well as components such as hand sprays and trolleys to meet consumer demand. Mergers and acquisitions supported the companies to improve their technical expertise and enabled them to offer enhanced products to consumers.Some prominent players in the global coating equipment market include:

-

Nordson Corporation

-

Gema Switzerland GmbH

-

J. Wagner GmbH

-

ANEST IWATA Corporation

-

Carlise Companies Inc

-

IHI Ionbond AG

-

Statfield

-

SAMES KREMLIN

-

The Eastwood Company

-

Graco Inc

-

RED LINE INDUSTRIES LIMITED

-

Pittsburgh Spray

-

Reliant Finishing Systems

-

ANEST IWATA USA, Inc.

-

IHI HAUZE B.V.

Coating Equipment Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 18,025.1 million

Revenue forecast in 2030

USD 225,993.5 million

Growth rate

CAGR of 5.3% from 2023 to 2030

Base year for estimation

2022

Historical data

2017 - 2021

Forecast period

2023 - 2030

Quantitative units

Revenue in USD million/billion and CAGR from 2023 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America, Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; France; Italy; U.K.; China; Japan; India; South Korea; Brazil; Argentina; South Africa; Saudi Arabia

Key companies profiled

Nordson Corporation; Gema Switzerland GmbH; J. Wagner GmbH; ANEST IWATA Corporation; Carlise Companies Inc; IHI Ionbond AG; Statfield; SAMES KREMLIN; The Eastwood Company; Graco Inc; RED LINE INDUSTRIES LIMITED; Pittsburgh Spray; Reliant Finishing Systems; ANEST IWATA USA, Inc.; IHI HAUZE B.V.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Coating Equipment Market Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global coating equipment market report based on product, application, and region:

-

Product Outlook (Revenue, USD Million, 2017 - 2030)

-

Specialty Coating Equipment

-

Powder Coating Equipment

-

Liquid Coating Equipment

-

-

Application Outlook (Revenue, USD Million, 2017 - 2030)

-

Automotive

-

Aerospace

-

Construction

-

Industrial

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2017 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

U.K.

-

France

-

Italy

-

-

Asia Pacific

-

China

-

Japan

-

India

-

South Korea

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Saudi Arabia

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global coating equipment market size was estimated at USD 16.62 billion in 2021 and is expected to be USD 17.24 billion in 2022

b. The coating equipment market, in terms of revenue, is expected to grow at a compound annual growth rate of 5.3% from 2022 to 2030 to reach USD 25.99 billion by 2030

b. Asia Pacific dominated the coating equipment market with a revenue share of 45.3% in 2021. This is attributable to the growing construction sector coupled with an improved budget for infrastructure development.

b. Some of the key players operating in the coating equipment market include: Nordson Corporation; Gema Switzerland GmbH; J. Wagner GmbH; ANEST IWATA Corporation; Carlise Companies Inc; IHI Ionbond AG; Statfield; SAMES KREMLIN; The Eastwood Company; Graco Inc; RED LINE INDUSTRIES LIMITED; Pittsburgh Spray; Reliant Finishing Systems; ANEST IWATA USA, Inc.; IHI HAUZE B.V.

b. Key factors that are driving the coating equipment market growth include growing demand for coating equipment from various applications such as automotive, aerospace, construction, and industries

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.