Bisphenol A Market Summary

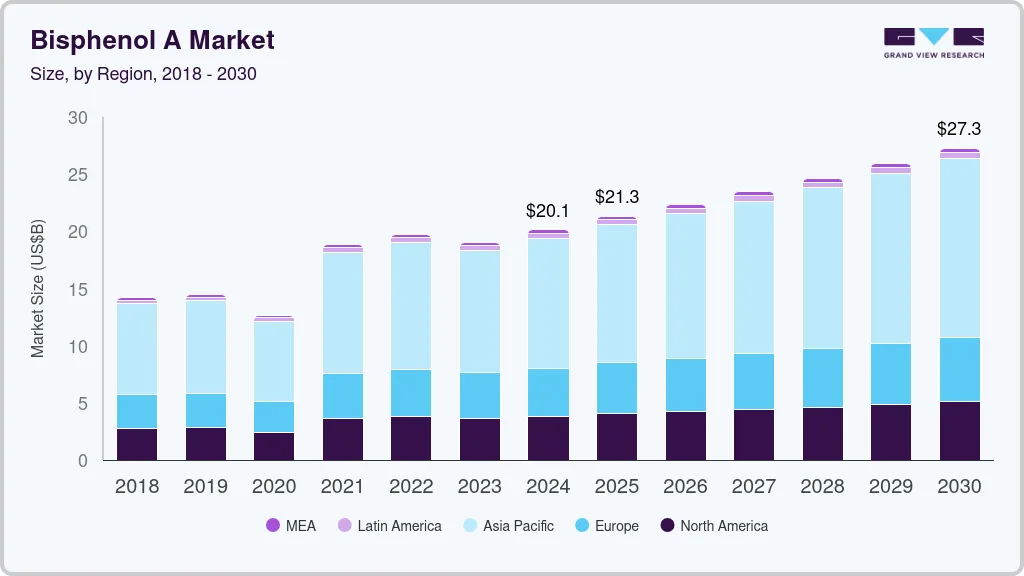

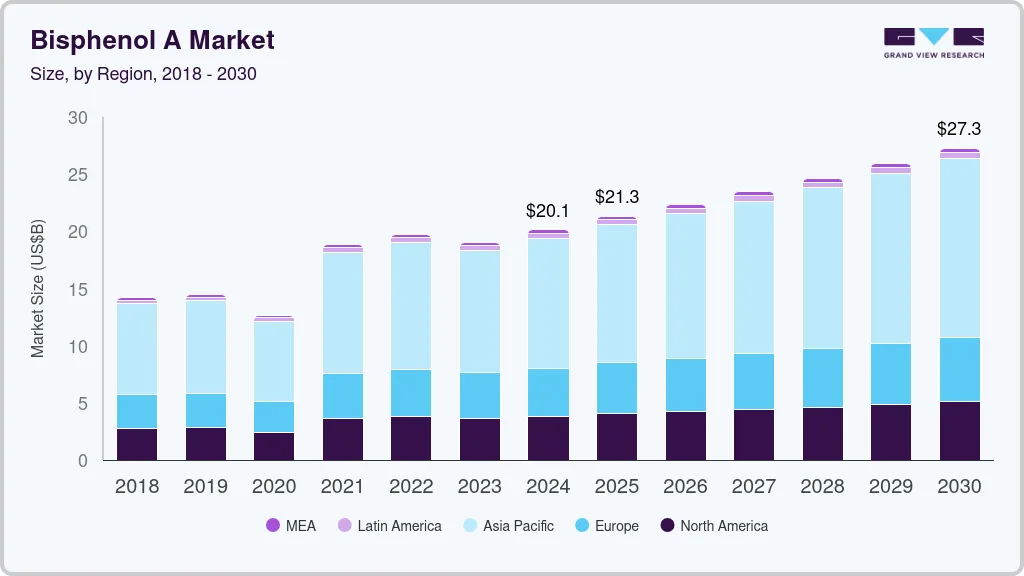

The global bisphenol A market size was estimated at USD 20,120.6 million in 2024 and is projected to reach USD 27,271.6 million by 2030, growing at a CAGR of 5.1% from 2025 to 2030. The rising need for bisphenol A in the growing electronics and automotive sectors is the key driving factor for the market.

Key Market Trends & Insights

- By region, Asia Pacific was the largest revenue generating market in 2023.

- Country-wise, China is expected to register the fastest CAGR from 2024 to 2030.

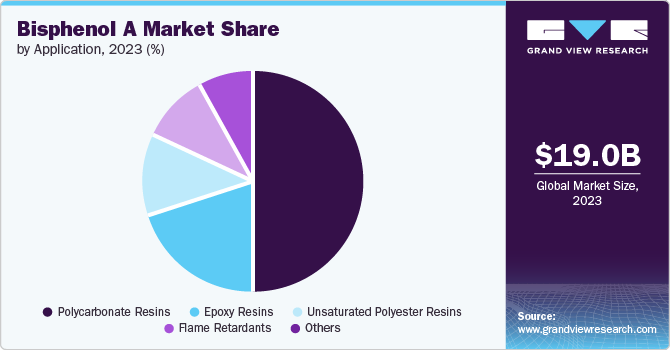

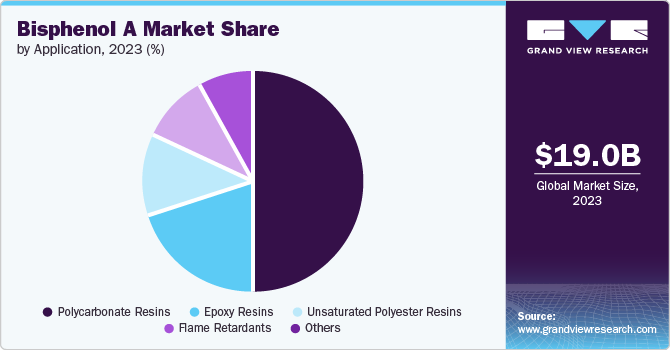

- By segment, polycarbonate resins accounted for a market share of 49.7% in 2023.

- Polycarbonate resins is the most lucrative application segment registering the fastest growth during the forecast period.

Market Size & Forecast

- 2024 Market Size: USD 20,120.6 million

- 2030 Projected Market Size: USD 27,271.6 million

- CAGR (2025-2030): 5.1%

- Asia Pacific: Largest market in 2023

Bisphenol A is commonly utilized in manufacturing polycarbonates and epoxy resins, which are subsequently applied in producing 3D printed circuit boards, LEDs, keyboards, computers, and more. The Bisphenol A market is expected to experience significant growth, driven by increasing demand in various end use industries such as automotive, construction, and electronics.

The demand for bisphenol A is increasing due to the rise in demand for polycarbonate plastics. It has been widely used in the automotive sector. Polycarbonate material is strong, lightweight, and can be mass produced. As automakers are manufacturing lighter and more fuel-efficient vehicles, they are increasingly opting for polycarbonate plastics over traditional materials such as glass and metal. Therefore, attributing to the upward market growth of the bisphenol A market.

Furthermore, the electronic sector has certainly played a significant role in the rising need for bisphenol A as it is used in manufacturing epoxy resin. The electronics industry uses epoxy resins due to their electrical insulation characteristics, strong mechanical properties, and resistance to heat and chemicals. Epoxy resins are used in various electronic applications, such as printed circuit boards, semiconductor packaging, and electronic encapsulation. Therefore, this increased demand for epoxy resins has resulted in the upward growth of this market.

Application Insights & Trends

“The epoxy resins segment to witness a growth rate of 5.1%”

Polycarbonate resins dominated the market and accounted for a market share of 49.7% in 2023, as they have a wide range of applications. These resins provide excellent impact resistance, clarity, and heat resistance. Polycarbonates are highly utilized in producing safety goggles, ballistic-resistant windows, healthcare instruments, and food packaging. Polycarbonate’s low cost and mass production capability make it a perfect alternative to materials such as glass and metals. Therefore, these factors are responsible for the upward market growth of this segment.

The epoxy resins segment accounted for a market share of 20.1% in 2023 due to its increased use in the automotive, aerospace, and electronics sectors. Epoxy resins offer durability, strength, and lightweight properties. Thus making it an ideal material for these industries. The rise of the construction industry has also resulted in the growth of this segment, as epoxy resin is used in the manufacturing of adhesives, coatings, and sealants. Furthermore, advancements in the research and development of epoxy resin products have also contributed to the market growth of this segment.

Regional Insights & Trends

North America bisphenol A market had a market share of 17.6%. This attributed to the rise in the need for polycarbonate plastics and epoxy resins in established industries such as paints and coatings, electronics, and medical sectors. Furthermore, the rise in the construction industry also attributed to the growth of this market.

U.S. bisphenol A market held a substantial share in the market due to the rise in the production of automobiles as the demand of polycarbonate resins has increased. Polycarbonate is used in the production of sunroofs, handles of doors, headlights and many more.

Asia Pacific Bisphenol A market Trends

Asia pacific dominated the bisphenol A market with a share of 59.6% in the year 2023 primarily due to the strong presence of end user industries and their requirement of bisphenol A. Increased production and sale of automobiles has also attributed to the upward market growth. Polycarbonate resins and epoxy resins are heavily used in manufacturing various parts of an automobile. The rise in construction activities in countries such as China, India, and Japan has also contributed to the market growth of bisphenol A.

China bisphenol A market is expected to grow rapidly in coming years due to significant use of polycarbonate resins and epoxy resins in the construction and automotive sectors. The increasing need for electric vehicles in the area is increasing the requirement for BPA-based plastics, which are used in manufacturing electric vehicle batteries. Furthermore, the rising paint and coatings industry is a significant driver behind the increasing demand for the market in the area.

Europe Bisphenol A market Trends

Europe bisphenol A market was identified as a lucrative region in this industry due to the strong presence of key industry players and a well-developed infrastructure. With the growth in the construction industry, the demand for epoxy resins required to manufacture adhesives, paints has increased. Many companies are using polycarbonate resins and epoxy resins as an alternative to glass and metals.

UK bisphenol A market is expected to grow rapidly in the coming years due the increased use of polycarbonate in the automotive industry. Rise in the manufacturing of medical devices made from polycarbonate material has also attributed to the market growth in this country.

Key Bisphenol A Market Company Insights

Some of the key companies operating in the bisphenol A market are Covestro AG, SABIC, Chang Chun Group, Mitsui Chemical Inc., Nan Ya Plastics Corporation, and Altivia. These companies are focusing on manufacturing various products out of polycarbonate and epoxy resins and selling them as an alternative to products made from glass and metal.

-

Covestro AG manufactures advanced polymer materials for multiple industries and offers a variety of products such as polycarbonates, isocyanates, polyols, and specialty chemicals used in construction, automotive, electronics, and sustainable solutions.

-

Nan Ya Plastics Corporation is a plastics manufacturer specialized in the manufacturing of plastic materials, electronic materials, polyester fibre, and plastics processing.

Key Bisphenol A Companies:

The following are the leading companies in the bisphenol a market. These companies collectively hold the largest market share and dictate industry trends.

- Covestro AG

- SABIC

- Chang Chun Group

- Mitsui Chemical Inc

- Nan Ya Plastics Corporation

- Altivia

- China National Bluestar (Group) Co. Ltd

- Mitsubishi Chemical Corporation

- HEXION INC

- LG Chem

Recent Developments

-

In December 2023, Nan Ya Plastics Corporation, a plastics manufacturing company unveiled a new bisphenol A production facility in Ningbo, China. According to the company, the facility was built in order to sustainably grow and respond to the market demand.

-

In February 2023, Mitsui chemicals, announced to provide biomass-derived bisphenol A to Mitsubishi chemicals company in order to manufacture biomass polycarbonate resins.

Bisphenol A Market Report Scope

|

Report Attribute

|

Details

|

|

Market size value in 2025

|

USD 21,304.4 million

|

|

Revenue forecast in 2030

|

USD 27,271.6 million

|

|

Growth Rate

|

CAGR of 5.1% from 2025 to 2030

|

|

Base year for estimation

|

2024

|

|

Historical data

|

2018 - 2023

|

|

Forecast period

|

2025 - 2030

|

|

Quantitative units

|

Revenue in USD million and CAGR from 2025 to 2030, Volume in Kilotons

|

|

Report coverage

|

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

|

|

Segments covered

|

Application, region

|

|

Regional scope

|

North America, Europe, Asia Pacific, Latin America, MEA

|

|

Country scope

|

U.S., Canada, Mexico, UK, Germany, France, Italy, Spain, Russia, Japan, China, India, Australia, South Korea, Indonesia, Thailand, Brazil, Argentina, South Africa, Saudi Arabia, UAE

|

|

Key companies profiled

|

Covestro AG, SABIC, Chang Chun Group, Mitsui Chemical Inc., Nan Ya Plastics Corporation, Altivia, China National Bluestar (Group) Co. Ltd, Mitsubishi Chemical Corporation, HEXION INC, LG Chem

|

|

Customization scope

|

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

|

|

Pricing and purchase options

|

Avail customized purchase options to meet your exact research needs. Explore purchase options

|

Global Bisphenol A Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the bisphenol A market report based on application, and region.

-

Application Outlook (Revenue, USD Million, 2018 - 2030, Volume in Kilotons)

-

Regional Outlook (Revenue, USD Million, 2018 - 2030, Volume in Kilotons)