- Home

- »

- Paints, Coatings & Printing Inks

- »

-

Coil Coatings Market Size & Share, Industry Report, 2033GVR Report cover

![Coil Coatings Market Size, Share & Trends Report]()

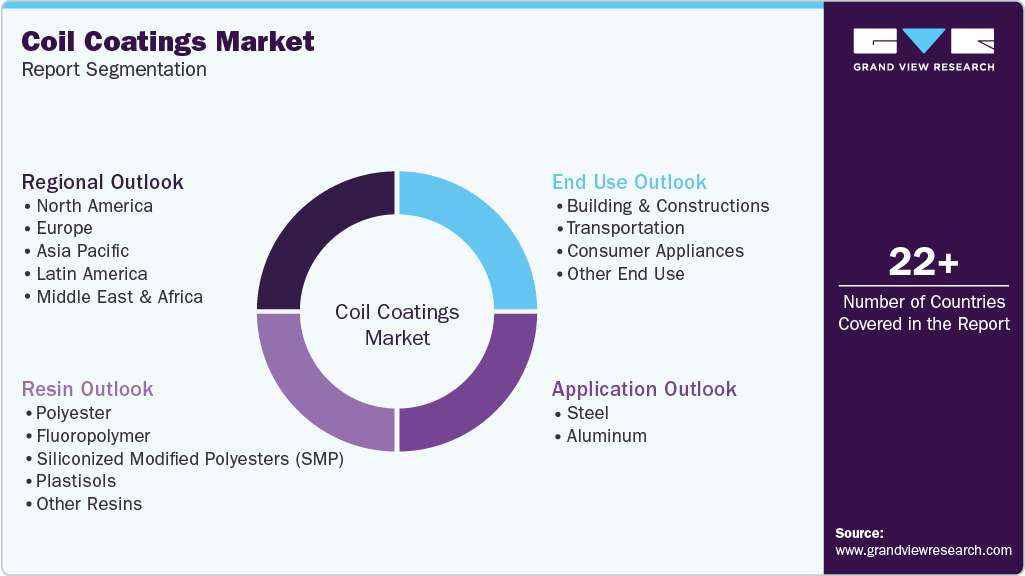

Coil Coatings Market (2026 - 2033) Size, Share & Trends Analysis Report By Resin (Polyester, Fluoropolymer, Siliconized Modified Polyesters (SMP)), By Application (Steel, Aluminum, Capsules), By End Use (Building & Constructions), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-326-7

- Number of Report Pages: 80

- Format: PDF

- Historical Range: 2018 - 2024

- Forecast Period: 2026 - 2033

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Coil Coatings Market Summary

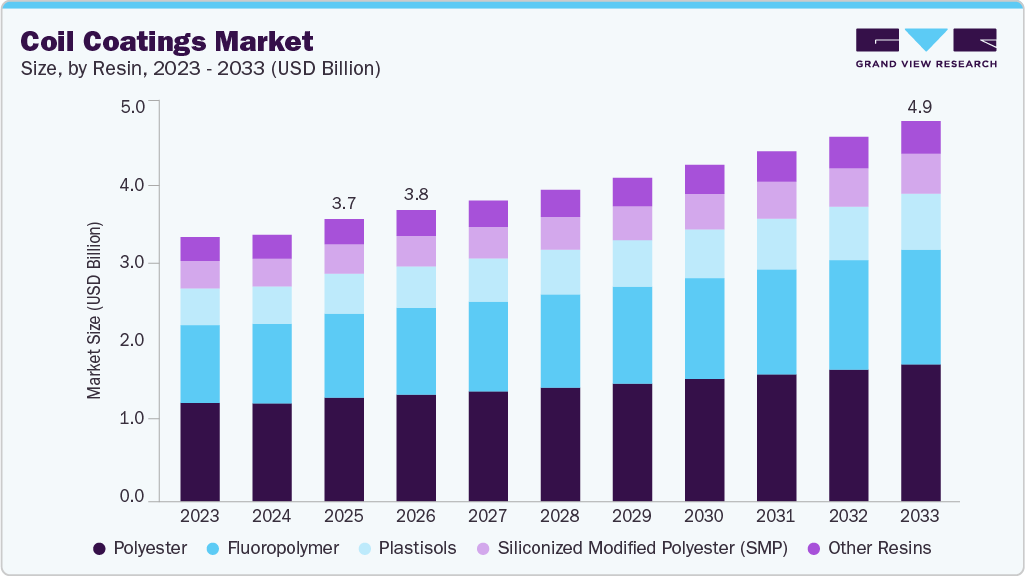

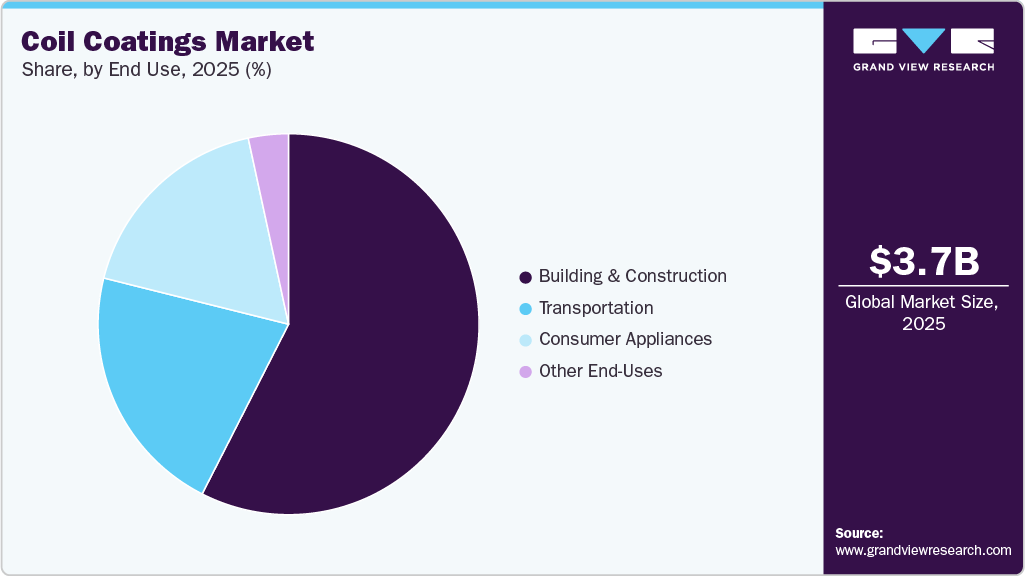

The global coil coatings market size was estimated at USD 3,681.8 million in 2025 and is projected to reach USD 4,959.3 million by 2033, growing at a CAGR of 3.9% from 2026 to 2033. This growth can be attributed to the increased demand for these coatings from the flourishing construction industry, which includes both residential and commercial sectors.

Key Market Trends & Insights

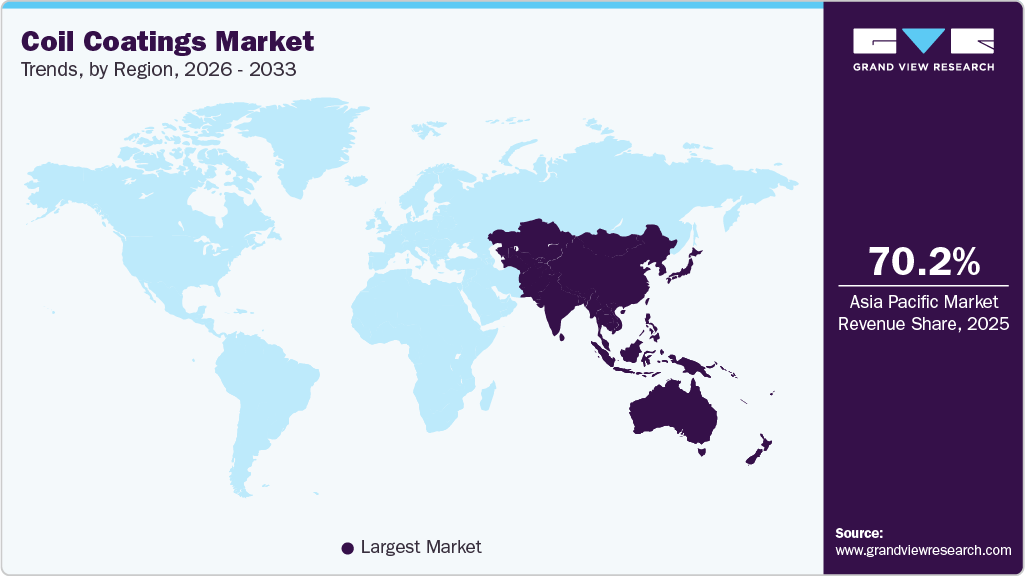

- The Asia Pacific dominated the market with largest revenue share of 70.2% in 2025.

- By resin, the polyester segment dominated the market and accounted for the largest revenue share of 36.8% in 2025.

- By application, the steel segment dominated the market and accounted for the largest revenue share of 73.8% in 2025.

- By end use, transportation segment is expected to grow fastest with a CAGR of 4.4% from 2026 to 2033.

Market Size & Forecasts

- 2025 Market Size: USD 3,681.8 Million

- 2033 Projected Market Size: USD 4,959.3 Million

- CAGR (2026-2033): 3.9%

- Asia Pacific: Largest Market in 2025

Coil coatings are extensively used in roofing, cladding, and insulation of buildings, infrastructure, and industrial facilities. One of the key advantages of coil coating is its ability to provide a consistent and controlled application of paint at high line speeds. This allows for rapid and efficient production, making it a preferred method for coating metal. The process ensures that the entire surface of the metal is cleaned and treated before the paint is applied, resulting in tightly-bonded finishes. The use of coil coating in the industry is extensive, with over 800 million tons of coil-coated metal produced and shipped annually in North America alone.The global construction industry is one of the major consumers of coil coatings in the world. It accounted for more than 40% share of the total global demand for coil coatings in 2023. Rapid urbanization and industrialization have also led to the need for construction and infrastructure development, especially in emerging countries of Asia Pacific, Central & South America, and the Middle East.

Advancements in coating technologies have revolutionized the applicability of coil coatings in recent years. These advancements have not only enhanced the performance and durability of coil coatings but have also expanded the range of their applications across industries. One such advancement is the development of high-performance polymer coatings, which provide excellent resistance to corrosion, UV radiation, and harsh weather conditions.

VOCs are subject to a variety of statutory regulations and legislation. The use of these organic compounds in coil coatings is regulated by government and federal agencies to limit human exposure to toxic substances and control VOC emissions. VOCs are regulated by international and national regulatory bodies by ensuring their legal conformity and environmental relevance, as well as assessing the raw materials used for developing them based on ecotoxicological and toxicological data. The European Chemical Industry Council (CEFIC), the German Chemical Industry Association, and many other scientific groups are constantly working to evaluate and develop coil coatings with low-VOC content for various industries.

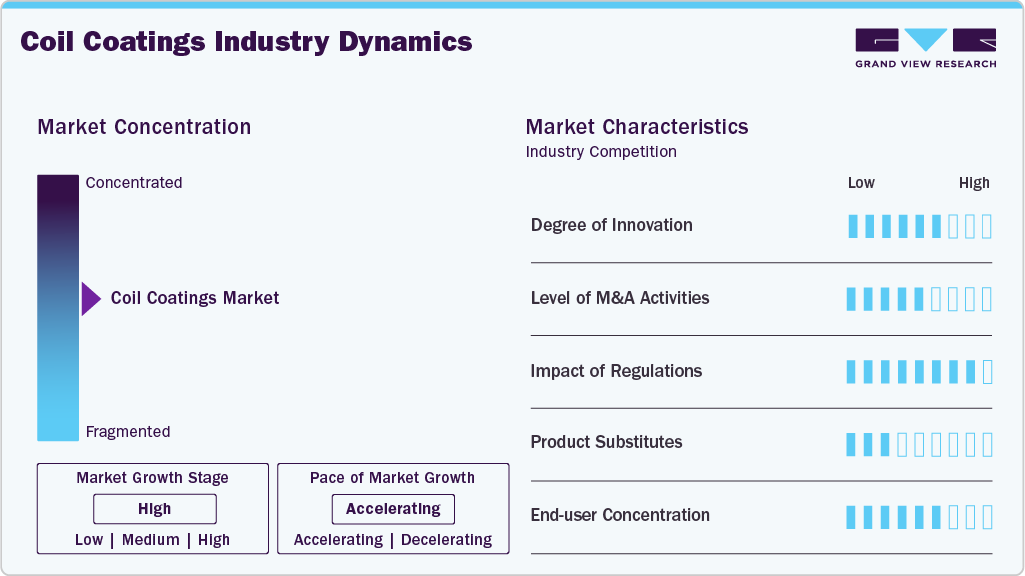

Market Concentration & Characteristics

The global market can be characterized as moderately consolidated, with a significant share of the market being held by top players in the industry. This level of consolidation is indicative of a market where a few key companies hold a substantial portion of the market share, leading to a competitive landscape with a degree of stability and influence exerted by these major players. This consolidation is driven by several factors, including the level of innovation required, research and development costs as well as strict regulatory environment.

Innovation plays a crucial role in the global coil coatings market, driving the development of new products, processes, and technologies. The industry is witnessing continuous evolution, fostering innovative formulations and solutions that cater to the diverse needs of end use industries. Notably, there is a growing emphasis on environmentally friendly solutions, with a focus on sustainable coating formulations, including low-VOC coatings, water-based formulations, and recycling programs. This emphasis on innovation aligns with the broader industry trend towards sustainability and environmental responsibility.

The global market faces the potential impact of product substitutes, particularly in the context of evolving consumer preferences and technological advancements. As the industry continues to innovate, the emergence of alternative coating technologies or materials could present competitive challenges. In addition, the market's response to the harmful environmental impact of solvent-borne coatings suggests a potential shift towards alternative products that align with stricter environmental regulations and sustainability goals.

Resin Insights

The polyester segment, dominated the source segment with a revenue share of 36.8% in 2025. Polyester resins are widely used in coil coating applications, which involve the application of a coating to a metal coil before it is formed into a final product. Polyester coatings are commonly used in industries such as construction, automotive, and aerospace. In this section, we will discuss the characteristics and applications of polyester resins used in coil coating.

The plastisols segment is the fastest-growing segment with a CAGR of 4.4% during the forecast period, driven by its expanding use in automotive underbody coatings, textile printing inks, and sealants. Its superior properties, such as excellent adhesion, flexibility, and chemical resistance-support adoption across high-performance end uses. Moreover, increasing demand for durable, corrosion-resistant coatings and advancements in low-VOC plastisol formulations are further accelerating market penetration.

Application Insights

The steel segment, dominated the application segment with a revenue share of 73.8% in 2025. The steel segment is a significant driver of the coil coatings market, owing to its applications in various industries, such as automotive, construction, and consumer appliances. Pre-painted steel is a color-coated construction material used for cladding, roofing, residential doors, and other structural purposes. The pre-painted steel products offer characteristics, such as corrosion resistance, durability, and aesthetics, which enhance product performance. The versatility and reliability of steel coated with coil coatings help in the adoption of these steel products in end use industries.

The aluminum segment is the fastest-growing segment with a CAGR of 4.1% during the forecast period. Growth is supported by increasing substitution of aluminum for steel in building façades, roofing, transportation panels, and appliance manufacturing due to its lightweight, corrosion resistance, and superior recyclability. In addition, rising adoption in energy-efficient and sustainable construction materials and the expansion of coated aluminum in EV body structures and HVAC applications are further driving demand.

End Use Insights

The building & construction segment, dominated the product segment with a revenue share of 57.5% in 2025. Coil coatings are applied to metal coils, such as steel and aluminum, before they are molded into various building components such as roofing, siding, windows, doors, and ceiling grids. These coatings enhance the durability, corrosion resistance, and aesthetic appeal of metal surfaces, making them suitable for use in various construction projects.

The transportation segment is expected to grow the fastest with a CAGR of 4.4%, during the forecast period. Coil coatings are widely used in the transportation industry for a range of applications in automotive, aerospace, and rail. Coil coatings are used in the automotive industry for coating metal components, such as car bodies, chassis, and engine parts. These coatings provide superior corrosion resistance, weatherability, and aesthetic appeal to vehicles. They also contribute to improving the fuel efficiency and performance of cars, trucks, and aircraft.

Regional Insights

The Asia Pacific dominated the market with largest revenue share of 70.2% in 2025. Accelerated urban development and industrial expansion across APAC countries are fueling consumption of coated metals. Coil coatings are increasingly utilized to enhance durability and aesthetics in commercial, residential, and infrastructure projects.

China Coil Coatings Market Trends

China’s expanding manufacturing sector and export-oriented metal production are key drivers for coil coatings. The coatings provide protective and decorative finishes critical for durable products in domestic and global markets.

North America Coil Coatings Market Trends

Rising investments in industrial facilities and infrastructure projects are driving demand for pre-finished metals. Coil coatings provide durable, low-maintenance solutions for construction and manufacturing applications, supporting rapid urbanization.

The U.S. coil coatings market is propelled by strong demand from automotive and appliance manufacturers. Pre-painted metals reduce production time and enhance durability, aligning with efficiency-focused manufacturing practices.

Europe Coil Coatings Market Trends

Stringent environmental regulations and a strong focus on sustainability are encouraging manufacturers to adopt low-VOC and eco-friendly coil coatings. This trend is boosting demand for high-performance, environmentally compliant solutions.

Germany’s market emphasizes precision, quality, and innovation in coil coatings, particularly for industrial and architectural applications. Advanced formulations and environmentally compliant products are preferred to meet stringent local standards.

Latin America Coil Coatings Market Trends

Ongoing modernization of commercial and industrial buildings is pushing demand for pre-finished metals. Coil coatings offer cost-effective, durable, and visually appealing solutions, supporting the region’s construction and industrial growth.

Middle East & Africa Coil Coatings Market Trends

Large-scale infrastructure and industrial projects across the Middle East & Africa are driving growth in coil-coated metal demand. The market benefits from a focus on long-lasting and corrosion-resistant solutions suitable for harsh environmental conditions.

Key Coil Coatings Company Insights

The competitive landscape of the global market is characterized by intense competition among a few key players, technological advancements, and strategic initiatives aimed at maintaining industry leadership and driving innovation. Large market incumbents such as Akzo Nobel N.V., DuPont, and BASF SE are prominent players in the industry, with established brand identities and considerable market penetration. These companies have a strong presence in the overall global coatings industry, leveraging their brand reputation to maintain market share and drive growth.

-

BASF SE is a leading player in the coil coatings market, offering a wide range of offerings such as Petrochemicals, Intermediates, Performance Resins, Monomers, Dispersion & Resins, Performance Chemicals, Catalysts, Coatings, Care Chemicals, Nutrition & Health, and Agricultural Solutions.

-

DuPont is a major player in the coil coatings industry. The company operates through its three business segments: Interconnect Solutions, Semiconductor Technologies, and Industrial Solutions, offering coil coatings under industrial solutions.

Key Coil Coatings Companies:

The following are the leading companies in the coil coatings market. These companies collectively hold the largest market share and dictate industry trends.

- PPG Industries, Inc.

- The Sherwin-Williams Company

- AkzoNobel N.V.

- DuPont

- BASF SE

- Henkel AG & Co. KGaA

- Kansai Nerolac Paints Limited

- Axalta Coating Systems

- Continental Coatings

- JSW Paints

- Nippon Paints Holdings Co., Ltd.

- Blygold

- HUEHOCO

Recent Developments

-

In June 2024, AkzoNobel invested USD 3.6 million to expand coil and extrusion coatings production at its Garcia, Mexico facility, boosting capacity and efficiency for North American customers. This investment follows earlier major upgrades in the U.S., strengthening the company’s overall manufacturing capability.

-

In July 2024, PPG launched its DURANEXT energy-curable coil coatings, enabling ultra-fast ambient-temperature curing and reduced energy use for coil coaters. The new EB and UV systems offer durable, customizable solutions designed to improve sustainability and production efficiency.

Coil Coatings Market Report Scope

Report Attribute

Details

Market size value in 2026

USD 3,797.6 million

Revenue forecast in 2033

USD 4,959.3 million

Growth rate

CAGR of 3.9% from 2026 to 2033

Base year for estimation

2025

Historical data

2018 - 2024

Forecast period

2026 - 2033

Quantitative units

Volume in kilotons, revenue in USD million/billion, and CAGR from 2026 to 2033

Report coverage

Revenue forecast, volume forecast, competitive landscape, growth factors, and trends

Segments covered

Resin, application, end use, region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; China; India; Japan; South Korea; Brazil; Argentina; Saudi Arabia; South Africa

Key companies profiled

PPG Industries, Inc.; The Sherwin-Williams Company; Akzo Nobel N.V.; DuPont; BASF SE; Henkel AG & Co. KGaA; Kansai Nerolac Paints Limited; Axalta Coating Systems; Continental Coatings; JSW Paints; Nippon Paints Holdings Co.,Ltd.; Blygold; HUEHOCO

Customization scope

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional, and segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Coil Coatings Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2033. For this study, Grand View Research has segmented the global coil coatings market report based on resin, end use, application, and region:

-

Resin Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2033)

-

Polyester

-

Fluoropolymer

-

Siliconized Modified Polyesters (SMP)

-

Plastisols

-

Other Resins

-

-

End Use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2033)

-

Building & Constructions

-

Transportation

-

Consumer Appliances

-

Other End Use

-

-

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2033)

-

Steel

-

Aluminum

-

-

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

Italy

-

Spain

-

France

-

-

Asia Pacific

-

China

-

Japan

-

South Korea

-

India

-

Singapore

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Saudi Arabia

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global coil coatings market was estimated at USD 3681.8 million in 2025 and is expected to reach USD 3797.6 million in 2026.

b. The global coil coatings market is expected to grow at CAGR of 3.9% from 2026 to 2033 to reach USD 4959.3 million by 2033.

b. The Asia-Pacific dominated the market with largest revenue share of 70.2% in 2025. Accelerated urban development and industrial expansion across APAC countries are fueling consumption of coated metals.

b. Some of the leading manufacturers of coil coatings are PPG Industries, Inc., The Sherwin-Williams Company, Akzo Nobel N.V., DuPont, BASF SE, Henkel AG & Co. KGaA, Kansai Nerolac Paints Limited, Axalta Coating Systems, Continental Coatings, and JSW Paints

b. The global coil coating market is expected to witness healthy growth over the forecast period, on account of its growing demand in construction, automotive and electrical & electronics industries, due to superior properties such as stain resistance, corrosion resistance, and flexibility compared to conventional coatings.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.