- Home

- »

- Paints, Coatings & Printing Inks

- »

-

High Temperature Coatings Market Size & Share Report 2030GVR Report cover

![High Temperature Coatings Market Size, Share & Trends Report]()

High Temperature Coatings Market (2023 - 2030) Size, Share & Trends Analysis Report By Resin (Epoxy, Silicone, Polyethersulfone, Polyester, Acrylic, Alkyd, Others), By Technology, By Application, By Region, And Segment Forecasts

- Report ID: GVR-1-68038-007-1

- Number of Report Pages: 115

- Format: PDF

- Historical Range: 2018 - 2021

- Forecast Period: 2023 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

High Temperature Coatings Market Trends

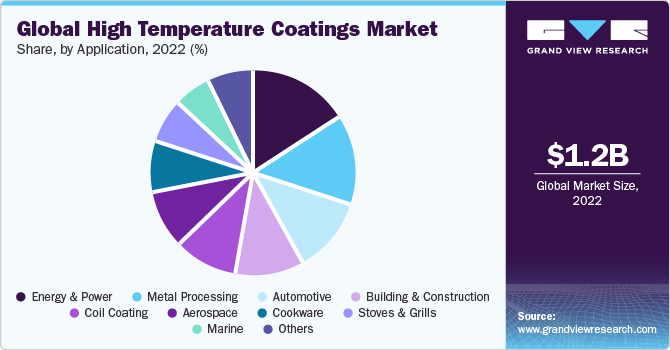

The global high temperature coatings market size was valued at USD 1,243.3 million in 2022 and is anticipated to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. The industry is anticipated to witness moderate growth over the next few years on account of increasing product demand across various technology industries such as metal processing, cookware and bakeware, and building and construction. A major benefit associated with these products is protection against corrosion due to prolonged equipment usage in fire and high-temperature environments. Fireproofing plays an essential part in the construction sector as it offers protection to structured steel and other parts of the building.

However, the lack of synergy among building codes in different countries is expected to hamper market penetration in the construction sector. Consistency in regulatory norms enables coating manufacturers to enhance their investments in R&D projects. Underwriters Laboratories (UL) is a major regulatory agency that has issued guidelines and standards for conducting application testing of coatings.

Other government and regulatory agencies such as ASTM, ANSI, ISO, and NFPA govern the testing and formulation of ingredients used in the coatings. Incidents of building collapse and occupational injuries due to fire have led to numerous

revisions in the safety norms to integrate flame-retardant inorganic agents in coating materials. Silicone, phosphorus, and halogen-based products have gained significance owing to their enhanced resilience to high-temperature environments.

Application Insights

The energy & power segment accounted for the largest revenue share of around 16.3% in 2022. Equipment such as furnaces, heaters, towers, and ducts used in refinery and chemical plants are exposed to heat and high temperature environments. Growing concerns over equipment durability and downtime are expected to drive the demand for heat resistant coatings with enhanced color stability and corrosion resilience.

The metal processing segment is expected to register a CAGR of 4.8% over the forecast period. Increased adoption of the product can be attributed to surging demand for metal equipment in the industrial and commercial sectors that can withstand rusting due to external weather. Metal piping, heavy equipment, and industrial machinery find usage in various applications such as forestry, agriculture, manufacturing, and waste treatment facilities. Growing concerns over equipment corrosion and degradation are expected to drive the segment over the forecast period.

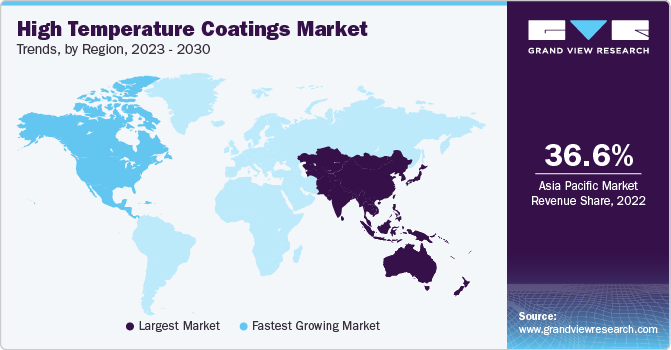

Regional Insights

Asia Pacific dominated the high temperature coatings market and accounted for the largest revenue share of 36.6% in 2022. Significant growth in the construction and automotive sectors, particularly in China, India, and Japan, is expected to drive product demand in the region. Moreover, rapid industrialization, increasing infrastructure development, and rising energy demand contribute to market growth in the region.

North America region is expected to grow at a CAGR of 4.1% during the forecast period. Wide product adoption in major technology industries including electronics, automobile, energy, and construction has contributed significantly to the industrial growth in this region. Renewal of reforms to incorporate thermally efficient materials and environment-friendly materials is expected to play a major role in steering product demand in the region.

Resin Insights

The acrylic segment accounted for the largest revenue share of 23.5% in 2022. Surging demand for heat-resistant coatings with decorative properties in building and transportation infrastructure has led to high penetration of acrylic-based products in various industries. Low volatile organic compound (VOC) content in the product formulation is another factor contributing to its increased adoption in the industries.

The epoxy segment is expected to grow at the fastest CAGR of 4.9% during the forecast period owing to its high durability and chemically resistant characteristics. Epoxy-based products find extensive usage in corrosion resistant applications including automobiles, boats, steel pipes, and transmission pipelines, which are exposed to high-temperature environments. Demand for epoxy based coatings is increasing due to their compatibility with a wide range of color formulations and solvent free ingredients.

Polyethersulfone (PES) is expected to emerge as the second fastest-growing segment. Increasing product demand can be attributed to its physical characteristics such as enhanced metal adhesion, transparency, and long-term thermal stability. These features have increased product usage in a broad range of applications including wood furniture, construction, automotive refinishes, and marine.

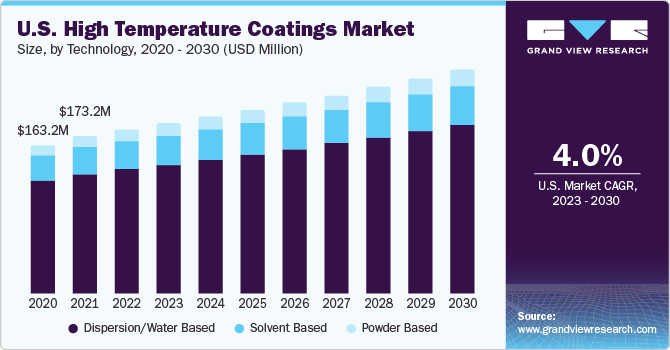

Technology Insights

The dispersion/water based segment held the largest revenue share of 75.9% in 2022. Shifting trend towards non-solvent based technologies has resulted in an increased adoption of waterborne and powder based products in various industrial sectors. In addition to low VOC content, surging demand for cost-effective products with minimal environmental impact is expected to drive the demand for waterborne applications over the next few years.

The powder based segment is expected to grow at the fastest CAGR of 5.6% over the forecast period. Stringent environmental regulations regarding solvent-based products have urged coating manufacturers to shift towards powder-based products. Major benefits associated with this application include higher utilization rates and ease of application, which are expected to drive the segment demand over the forecast period.

Key Companies & Market Share Insights

The global market is moderately fragmented due to the presence of a large number of multinational corporations such as BASF, PPG Industries, Sherwin-Williams, Axalta Coating Systems, Jotun AS, and Akzo Nobel NV. Key strategies adopted by these industry players include long-term partnerships with raw material suppliers to achieve economies of scale and subsequently offer products at a lower price than competitors.

Key High Temperature Coatings Companies:

- BASF SE

- Akzo Nobel N.V.

- The Sherwin-Williams Company

- PPG Industries, Inc.

- Valspar

- Carboline Company

- Axalta Coating Systems, LLC

- Jotun

- Aremco

- Belzona International Ltd.

- Chemco International Ltd

- Hempel A/S

- Weilburger Coatings GmbH

- GENERAL MAGNAPLATE CORPORATION

Recent Development

-

In June 2023, PPG Industries, Inc. introduced PPG ENVIRO-PRIME EPIC 200R coatings, a range of electrocoat (e-coat) products that offer lower temperature curing compared to alternative technologies. These coatings deliver sustainability advantages to customers by reducing energy consumption and minimizing CO2 emissions during the manufacturing process.

-

In June 2023,Sherwin-Williams introduced a new line of Heat-Flex CUI-mitigation coatings. The line features Heat-Flex ACE (Advanced CUI Epoxy), an ultra-high-solids epoxy novolac with a specialized chemical enhancement for effective corrosion under insulation (CUI) mitigation. The company claims that this advanced coating formulation surpasses other alternatives in mitigating CUI-related risks.

-

In May 2023, Akzo Nobel N.V. introduced a new bisphenol-free internal coating for beverage can end, providing coil coaters and can makers with a viable alternative as they accelerate their transition away from bisphenol-based coatings. This innovative BPA-NI (Bisphenol A non-intent) coating addresses the projected increase in demand for alternative coatings following the recent opinion of the European Food Safety Authority (EFSA) on the restrictions of BPA in metal packaging for food and beverage products. AkzoNobel's product launch aligns with the growing need for alternative coatings and supports the industry's efforts to comply with the evolving regulatory landscape.

High Temperature Coatings Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 1,294.9 million

Revenue forecast in 2030

USD 1.74 billion

Growth rate

CAGR of 4.3% from 2023 to 2030

Base year for estimation

2022

Historical data

2018 - 2021

Forecast period

2023 - 2030

Report updated

October 2023

Quantitative units

Revenue in USD million, Volume in Kilotons, and CAGR from 2023 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Resin, technology, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; MEA

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; Russia; China; Japan; India; South Korea; Brazil; Argentina; Saudi Arabia; South Africa

Key companies profiled

BASF SE; Akzo Nobel N.V.; The Sherwin-Williams Company; PPG Industries, Inc.; Valspar; Carboline Company; Axalta Coating Systems, LLC; Jotun; Aremco; Belzona International Ltd.; Chemco International Ltd; Hempel A/S; Weilburger Coatings GmbH; GENERAL MAGNAPLATE CORPORATION

Customization scope

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global High Temperature Coatings Market Report Segmentation

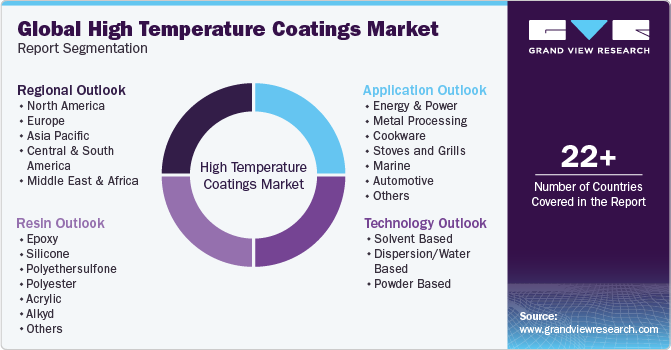

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global high temperature coatings market based on resin, technology, application, and region:

-

Resin Outlook (Revenue, USD Million; Volume, Kilotons, 2018 - 2030)

-

Epoxy

-

Silicone

-

Polyethersulfone

-

Polyester

-

Acrylic

-

Alkyd

-

Others

-

-

Technology Outlook (Revenue, USD Million; Volume, Kilotons, 2018 - 2030)

-

Solvent Based

-

Dispersion/Water Based

-

Powder Based

-

-

Application Outlook (Revenue, USD Million; Volume, Kilotons, 2018 - 2030)

-

Energy & Power

-

Metal Processing

-

Cookware

-

Stoves and Grills

-

Marine

-

Automotive

-

Coil Coating

-

Aerospace

-

Building & Construction

-

Others

-

-

Regional Outlook (Revenue, USD Million; Volume, Kilotons, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

Russia

-

-

Asia Pacific

-

China

-

Japan

-

India

-

South Korea

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East and Africa

-

Saudi Arabia

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global high temperature coatings market size was estimated at USD 1,243.3 million in 2022 and is expected to reach USD 1,294.9 million in 2023.

b. The global high temperature coatings market is expected to grow at a compound annual growth rate of 4.3% from 2023 to 2030 to reach USD 1.74 billion by 2030.

b. Asia Pacific dominated the high temperature coatings market with a share of 36.6% in 2022. This is attributable to the rising construction and automotive industries, particularly in China, India, and Japan.

b. Some key players operating in the high temperature coatings market include BASF SE; PPG Industries, Sherwin-Williams, Axalta Coating Systems, Jotun AS, and Akzo Nobel NV.

b. Key factors that are driving the market growth include increasing product demand from various applications, including metal processing, cookware and bakeware, and building and construction and growing concerns over equipment durability and life.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.