- Home

- »

- Organic Chemicals

- »

-

Leather Chemicals Market Size Report, 2022 - 2030GVR Report cover

![Leather Chemicals Market Size, Share & Trends Report]()

Leather Chemicals Market (2022 - 2030) Size, Share & Trends Analysis Report By Product (Biocides, Surfactants), By Process (Tanning & Dyeing, Beamhouse), By Application (Footwear, Upholstery), By Region, And Segment Forecasts

- Report ID: GVR-2-68038-816-9

- Number of Report Pages: 118

- Format: PDF

- Historical Range: 2017 - 2020

- Forecast Period: 2022 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Report Overview

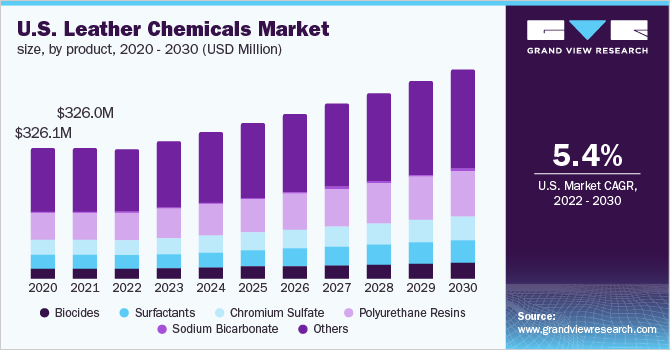

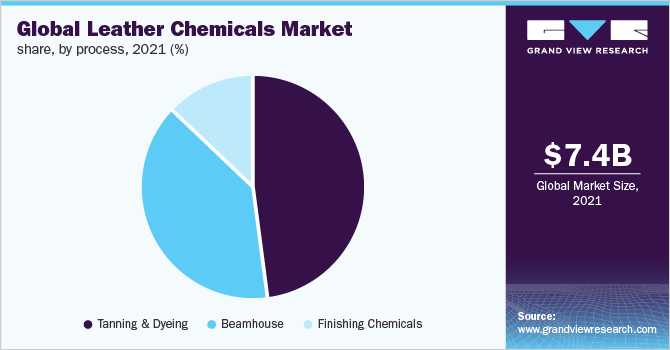

The global leather chemicals market size was valued at USD 7.4 billion in 2021 and is anticipated to expand at a compound annual growth rate (CAGR) of 6.6% from 2022 to 2030. The demand for the product is anticipated to be driven by increased demand for premium products. Increasing disposable income along with the rising population in developing economies is expected to boost demand for consumer products, driving the product industry. The fast-developing upholstery sector, which finds application in airplanes, furniture, and automobiles, has been a major driver of leather demand in the past and will continue to be in the future. It can be found in abundance in high-end furniture and automobiles. Upholstery is easy to maintain, long-lasting, and opulent. It is already available in small vehicle models from premium brands.

Another developing area for upholstery is airplane interiors in which high performance leather makes it a suitable choice for engineers, designers as well as cost controllers. High performance product are enhanced by processing the product with the product and additives. The above-mentioned factors are expected to increase the consumption of the product in automotive industry, thus propelling the growth of the market for leather chemicals over the forecast period. The demand for footwear is increasing as the world's population grows and consumer spending power grows in developing countries. Individuals now want diverse as well as different styles of footwear, changing the dynamics of the footwear sector.

The product is used to give footwear dimensional strength, endurance to high temperatures, and mechanical action, making it more durable. Integration across the value chain is expected to be a key factor in the market, as most manufacturers strive to reduce costs, necessitating both backward and forward integration. As a result of solid tie-ups at different distribution levels, relationships between manufacturers and suppliers are becoming stronger. Over the projected period, this is expected to be a significant factor for businesses to obtain a competitive advantage.

Leather undergoes various processes involving the use of the product in order to make it long-lasting and give it a rich appeal. The demand for the product is expected to witness growth on account of their increasing use to improve the aesthetic value, texture, and color of leather along with the use of nanoparticles and microparticles for imparting greater water and abrasion resistance as well as better finish adhesion. Rising demand for a wide variety of products such as footwear, apparels, automotive and furniture upholstery, and garments is expected to be the major driving factor for the growth of the market for leather chemicals.

Product Insights

The polyurethane resins product segment dominated the market for leather chemicals and accounted for revenue share of 22.9% in 2021. The higher share is attributed to increase in consumption of polyurethane in leather processing. They're also utilized to make organic solvent-free finish formulations, as well as binders, basecoats, and topcoats. Hybrid acrylic polyurethane polymers have made significant contributions to solvent-free finish formulations. Because of their high tensile strength, outstanding elasticity, and abrasion and solvent resistance, PU resins are used to make PU-based synthetic products in addition to their application in other formulations and processing. The need for PU resins in the manufacturing industry is expected to rise, as PU-based leather is considered more environmentally friendly than vinyl-based leather. However, because of the lengthy manufacturing process involved, it is the more expensive of the two.

The surfactants segment is expected to witness a CAGR of 7.0% over the forecast period. The demand is attributed to increase in its utilization as surface-active agents in the leather-making process. They are not only used as emulsifiers or main reaction agents but also as anti-electrostatic, water repellent, and abrasion reduction agents. Moreover, such agents can be used to ease the dispersion of oils in water. Which in turn is expected to drive the growth of the market for leather chemicals.

The Chromium Sulfate segment was valued at USD 818.0 million in terms of revenue in 2021. The demand is attributed to its commonly utilization as tanning agent in leather industry, which is anticipated to drive the demand for the product. It is also used to manufacture chrome-based dyes, which are applied in the dying process. Chromium salts are used to tan a large amount of the leather produced, ranging from 80% to 90%. The major purpose of tanning chemicals like these is to stabilize leather by crosslinking collagen fibres. In tanning and retention operations, trivalent chromium agents are often used. However, the oxidation of trivalent chromium to hexavalent chromium is predicted to remain a critical challenge for leather manufacturers in certain scenarios.

Process Insights

The tanning and dyeing process segment accounted for a revenue share of more than 48.0% in 2021. It is anticipated to witness a CAGR of 6.7% over the forecast period owing to its various operations such as pickling, degreasing, tanning, swimming, shaving, retanning, dyeing, fatliquoring, and drying among others. Additional processes such as neutralization and bleaching depend on the condition of tanned hides and are implemented accordingly.

The beamhouse segment is anticipated to witness the second-largest CAGR of 6.6% over the forecast period. The growth is anticipated to be driven by its application ranging from preparation of hides and skins to preservation. It includes operations such as wetting & soaking, liming and unhairing, and deliming and bating. The chemicals used in such a process vary according to the hides and skins of different animals. The product used in such processes include enzymes, degreasers, sodium sulfide, lime, sulfuric acid, and formic acid.

Finishing process refers to stages after the drying process. It includes mechanical finishing operations and coatings. Leather can be finished in various ways through buffing, spray-coated, treatment with pigment, resins, dyes, or lacquered with urethane. Finishing coats include the base, intermediate, and topcoats. Main components and additives used in this process include surfactants and polyurethane resins. Increasing demand for premium products along with growing inclination of manufacturers toward aesthetic parameters is likely to drive the demand for leather chemicals over the forecast period.

Application Insights

The footwear application segment accounted for revenue share of more than 49.9% in 2021. The demand is attributed to increase in demand for leather used for manufacturing footwear, which, in turn, is driving demand for the product in footwear industry. Basic components of footwear include leather, rubber, plastic, textile, and metal among others. It is used in various application such as leather finishing, tanning, and dyeing among others. These chemicals are also used for strengthening the crust and filling.

The upholstery segment is expected to register the second-highest CAGR of 6.5% in the market for leather chemicals over the forecast period. The growth is anticipated to extensive coating applications. One of the major factors contributing to the growth of upholstery is increased use of soft leather in automotive and furniture industry. Upholstery includes leather for automotive and furniture sectors. Aniline, semi-aniline, and pigmented/protected leathers are extensively used in automotive and furniture upholstery, owing to which leather chemicals required for tanning, beam housing, retanning, waterproofing, and fatliquoring of such leathers are consumed on a large scale.

Wallets, belts, and other accessories are examples of leather items. In comparison to other end-use segments, the amount of leather required for such products is quite low. As a result, the leather goods segment's demand for the product is predicted to expand at a moderate rate. Tanning and dyeing chemicals, followed by finishing chemicals, are used extensively in the manufacturing of goods. Over the forecast period, rising consumer inclination toward product aesthetics, combined with rising demand for luxury leather products, is expected to increase demand for the product in leather goods.

Regional Insights

Asia Pacific dominated the market for leather chemicals and accounted for revenue share of more than 50.0% in 2021. The demand is attributed to the abundant availability of raw materials and the high concentration of product manufacturers. One of the primary elements propelling market growth in Asia Pacific is the low-cost labor. Because of the country's substantial imports of footwear and luxury consumer goods, the product's penetration in the country's product industry is limited. However, Japan's vehicle industry is well-established, and the country consumes a considerable amount of the product. Rising demand for products from the automobile industry is expected to be a major driving force in the country's product market.

In Europe, the leather chemicals market is anticipated to witness the second-largest CAGR of 6.9% over the forecast period. The growth is anticipated as it drives the consumer appliances, automobile, and footwear, industry. The tanning business in Europe is heavily reliant on raw resources and export. The market for leather chemicals is likely to increase in the next years due to rising demand for the product in manufacturing for footwear, furniture, automobile interiors, and apparel, among other applications. The luxury market is predicted to drive the country's market expansion, therefore the product market in Italy is highly focused and robust. Vegetable tanning is becoming more popular in the region, and it is likely to mimic some of the benefits of chromium, which is expected to add to the increase of chemicals used in synthetic leather manufacturing.

In Central and South America, the market for leather chemicals is expected to be driven by the growing industry in Brazil. The Brazilian product industry is characterized by extensive production of footwear & goods, especially travel accessories, and a strong connection with the U.S. market. The aforementioned characteristics have resulted in lucrative growth opportunities in the market for leather chemicals in the region.

Key Companies & Market Share Insights

The market for leather chemicals is highly competitive with the big international brands focusing on the development of long-term relationships with the end-users. With the further increase in the footwear, upholstery, and garments sector, the competition is anticipated to increase in the coming years. Companies such as Bayer AG, Lanxess AG, Elementis plc, and Chemtan Company Inc. have a high degree of integration across the value chain as they are also engaged in the production of caprolactam. These companies have established themselves as key manufacturers and focus on research and development for novel uses of the product. Some of the prominent players in the leather chemicals market include:

-

Stahl International B.V

-

Lanxess AG

-

Bayer AG

-

Elementis plc

-

Texapel

-

Chemtan Company Inc.

-

Lawrence Industries Limited

Leather Chemicals Market Report Scope

Report Attribute

Details

Market size value in 2022

USD 7.44 billion

Revenue forecast in 2030

USD 13.2 billion

Growth Rate

CAGR of 6.6% from 2022 to 2030

Base year for estimation

2021

Historical data

2017 - 2020

Forecast period

2022 - 2030

Quantitative units

Revenue in USD million and CAGR from 2022 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, process, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Italy; Spain; France; Turkey; China; India; Japan; Brazil; Saudi Arabia

Key companies profiled

Stahl International B.V; Lanxess AG; Bayer AG; Elementis plc; Texapel; Chemtan Company Inc.; Lawrence Industries Limited

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional, and segment scope

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Segments Covered in the ReportThis report forecasts revenue growth at global, regional, and country levels and provides an analysis on the latest industry trends in each of the sub-segments from 2017 to 2030. For the purpose of this study, Grand View Research has segmented the global leather chemicals market report on the basis of product, process, application, and region:

-

Product Outlook (Revenue, USD Million, 2018 - 2030)

-

Biocides

-

Surfactants

-

Chromium Sulfate

-

Polyurethane Resins

-

Sodium Bicarbonate

-

Others

-

-

Process Outlook (Revenue, USD Million, 2018 - 2030)

-

Tanning & Dyeing

-

Beamhouse

-

Finishing Chemicals

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Footwear

-

Upholstery

-

Leather Goods

-

Garments

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Italy

-

Spain

-

France

-

Turkey

-

-

Asia Pacific

-

China

-

India

-

Japan

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Saudi Arabia

-

-

Frequently Asked Questions About This Report

b. The global leather chemicals market size was estimated at USD 7.4 billion in 2021 and is expected to reach USD 7.44 billion in 2022.

b. The global leather chemicals market is expected to grow at a compound annual growth rate of 6.6% from 2022 to 2030 to reach USD 13.2 billion by 2030.

b. Asia Pacific region dominated the market with more than 50.0% in terms of value in 2021. The demand is attributed to the abundant availability of the raw materials and high concentration of product manufacturers.

b. Some key players operating in the leather chemicals market include Stahl Holdings B.V., Lanxess AG, Elementis Plc, and Bayer AG.

b. Key factors that are driving the leather chemicals market growth include high demand from the rapidly rising apparel industry, a rise in disposable incomes along with increased penetration of the organized retail sector.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.