- Home

- »

- Advanced Interior Materials

- »

-

Magnetic Separator Market Size, Industry Report, 2033GVR Report cover

![Magnetic Separator Market Size, Share & Trends Report]()

Magnetic Separator Market (2025 - 2033) Size, Share & Trends Analysis Report By Product (Magnetic Drum Separator, Overband/Cross Belt Separator), By End Use (Waste Management, Processing Industry), By Material Type (Wet, Dry), By Magnet Type (Electromagnets, Permanent Magnet), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-790-3

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2021 - 2023

- Forecast Period: 2025 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Magnetic Separator Market Summary

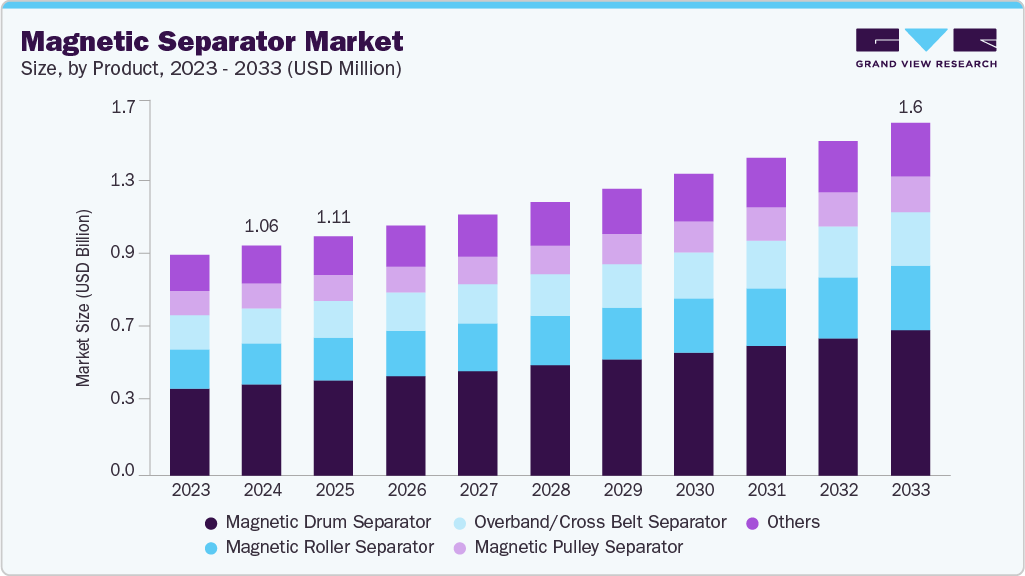

The global magnetic separator market size was estimated at USD 1,067.6 million in 2024 and is projected to reach USD 1,642.5 million by 2033, growing at a CAGR of 5.0% from 2025 to 2033. The global magnetic separator market is primarily driven by the growing demand for efficient mineral processing solutions.

Key Market Trends & Insights

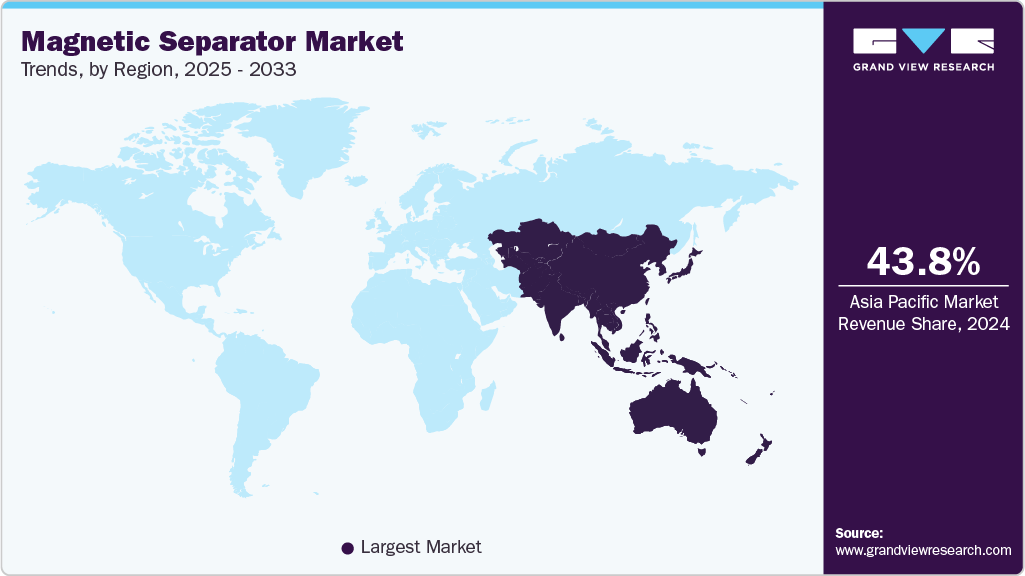

- Asia Pacific dominated magnetic separator market with the largest revenue share of 43.8% in 2024.

- The magnetic separator market in the U.S. is expected to grow at a substantial CAGR of 5.5% from 2025 to 2033.

- By product, magnetic drum separator segment is expected to grow at a considerable CAGR of 5.5% from 2025 to 2033 in terms of revenue.

- By material type, wet segment is expected to grow at a considerable CAGR of 5.3% from 2025 to 2033 in terms of revenue.

- By end use, waste management segment is expected to grow at a considerable CAGR of 5.4% from 2025 to 2033 in terms of revenue.

Market Size & Forecast

- 2024 Market Size: USD 1,067.6 Million

- 2033 Projected Market Size: USD 1,642.5 Million

- CAGR (2025-2033): 5.0%

- Asia Pacific: Largest market in 2024

Magnetic separators help in separating valuable metals from ores, enhancing recovery rates, and reducing operational costs. The rise in mining activities, especially in emerging economies, has further fueled the need for advanced separation technologies.

Another key factor propelling the market is the advancement in technology and automation of magnetic separators. Modern separators offer higher precision, energy efficiency, and ease of maintenance, attracting a wide range of industrial applications. The demand for high-quality raw materials in steel, ceramics, and electronics further boosts adoption. Environmental regulations and the focus on reducing waste have also contributed to the market’s steady growth globally.

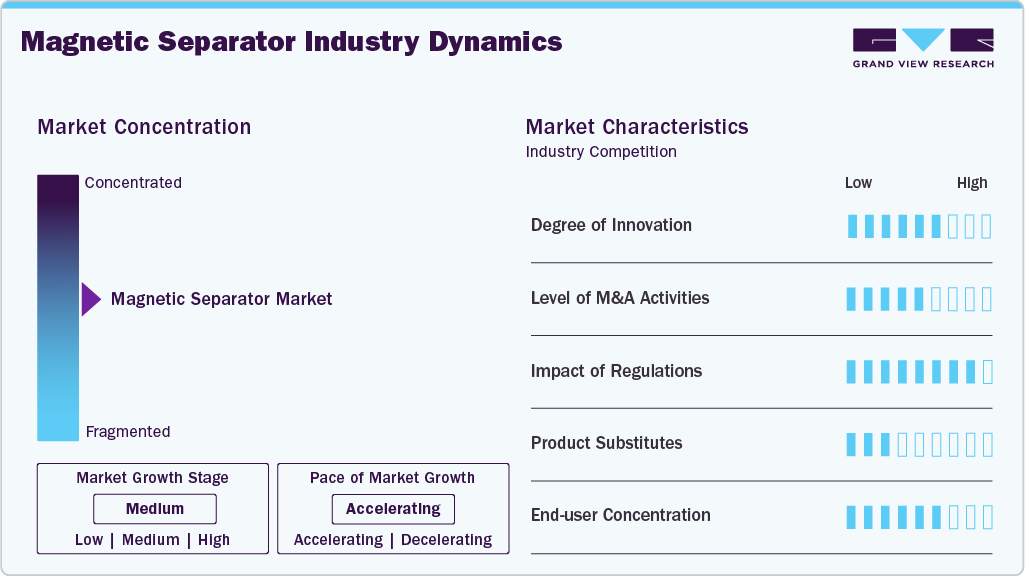

Market Concentration & Characteristics

The global magnetic separator industry is moderately concentrated, with a few key players holding significant market share while numerous smaller manufacturers operate regionally. Leading companies focus on innovation, customized solutions, and strategic partnerships to strengthen their presence. Despite the dominance of major players, the entry of new technology-driven firms has increased competition in niche applications. This balance of established brands and emerging players creates a dynamic market landscape with opportunities for growth and specialization.

The magnetic separator industry experiences moderate to high innovation, driven by the need for improved efficiency and precision in material separation. Companies invest in research and development to enhance automation, energy efficiency, and recovery rates. Innovations such as high-intensity magnetic separators and sensor-based sorting systems are becoming increasingly common. This focus on technological advancement helps manufacturers meet the evolving demands of mining, recycling, and industrial sectors.

Regulatory frameworks significantly influence the magnetic separator market, particularly environmental and safety standards. Companies must comply with regulations related to waste management, emissions, and workplace safety, which affects product design and operations. Adherence to such standards encourages the adoption of eco-friendly and energy-efficient technologies. Consequently, regulation acts as both a challenge and a driver for market innovation and sustainability.

The market sees a varied concentration of end users, with mining, steel, and recycling industries being the primary consumers. Large mining companies and industrial players often engage in long-term contracts, providing stability to manufacturers. At the same time, smaller enterprises rely on cost-effective and versatile magnetic separation solutions. This mix of high-volume industrial clients and diverse smaller users shapes market dynamics and product development strategies.

Drivers, Opportunities & Restraints

The global magnetic separator market is driven by the increasing demand for efficient mineral processing and metal recovery solutions. Rising mining activities and growth in the recycling sector further boost adoption. Technological advancements in high-intensity and automated separators enhance operational efficiency. In addition, industries such as steel, ceramics, and electronics are increasingly relying on magnetic separation to meet quality and sustainability standards.

There are significant growth opportunities in emerging economies where industrialization and mining activities are expanding rapidly. Development of advanced, energy-efficient, and sensor-based separators opens new application areas. Increasing focus on sustainable waste management and resource recovery presents potential market expansion. Strategic collaborations and customized solutions for niche applications also offer avenues for revenue growth.

High initial investment and maintenance costs of advanced magnetic separators limit adoption among small and medium enterprises. Fluctuations in raw material prices and mining output can affect market stability. Technical challenges in handling complex ore compositions and contamination risks pose operational constraints. In addition, strict environmental and safety regulations can increase compliance costs, restricting market growth in some regions.

Product Insights

“Magnetic roller separator segment is expected to grow at a significant CAGR of 5.2% from 2025 to 2033 in terms of revenue.”

The magnetic drum separator segment dominates the global market and accounted for a share of 39.5% in 2024 due to its versatility and efficiency in separating ferrous materials from bulk solids. It is widely used in mining, recycling, and industrial processes for high-volume operations. Its robust design, ease of maintenance, and reliable performance make it a preferred choice for large-scale applications. In addition, consistent technological improvements have enhanced its magnetic strength and separation precision, reinforcing its market leadership.

The magnetic roller separator segment is experiencing significant growth, driven by increasing demand for precise separation in industries such as food, chemicals, and electronics. Its ability to handle fine particles and delicate materials efficiently makes it suitable for specialized applications. Rising awareness about resource recovery and waste reduction further boosts adoption. Continuous innovation in design and automation is also contributing to the rapid expansion of this segment globally.

Material Type Insights

“Dry segment is expected to grow at a significant CAGR of 4.6% from 2025 to 2033 in terms of revenue.”

Wet magnetic separators dominate the market and accounted for a share of 58.2% in 2024 due to their efficiency in handling fine and sticky materials in mineral processing and mining applications. They provide higher recovery rates and better separation performance compared to dry systems. Industries such as mining, ceramics, and chemicals rely heavily on wet separation for consistent output quality. Continuous improvements in magnetic strength and slurry handling capabilities further reinforce their widespread adoption.

Dry magnetic separators are growing significantly as industries seek low-maintenance and energy-efficient solutions for powder and bulk material separation. They are increasingly used in recycling, food processing, and non-metallic mineral applications. The rising demand for environmentally friendly and dust-free operations drives their adoption. Advancements in design, such as high-intensity and roll-based separators, are expanding their applicability across diverse sectors.

Magnet Type Insights

“Permanent magnet segment is expected to grow at a significant CAGR of 4.4% from 2025 to 2033 in terms of revenue”

Electromagnets dominate the magnetic separator market and accounted for a share of 58.7% in 2024 due to their adjustable magnetic strength and suitability for large-scale industrial applications. They are widely used in mining, steel, and recycling industries where precise control over separation is required. The ability to handle high volumes and recover valuable metals efficiently reinforces their preference. Continuous technological enhancements, including energy-efficient designs, further strengthen their market position.

Permanent magnets are experiencing significant growth owing to their low operational costs and compact design, making them ideal for small to medium-scale applications. Industries such as food processing, plastics, and specialty chemicals increasingly adopt permanent magnet separators for efficient ferrous removal. Rising demand for energy-saving and maintenance-free solutions drives this segment. Advancements in high-strength magnetic materials further expand their application potential globally.

End Use Insights

“Processing Industry segment is expected to grow at a significant CAGR of 4.9% from 2025 to 2033 in terms of revenue”

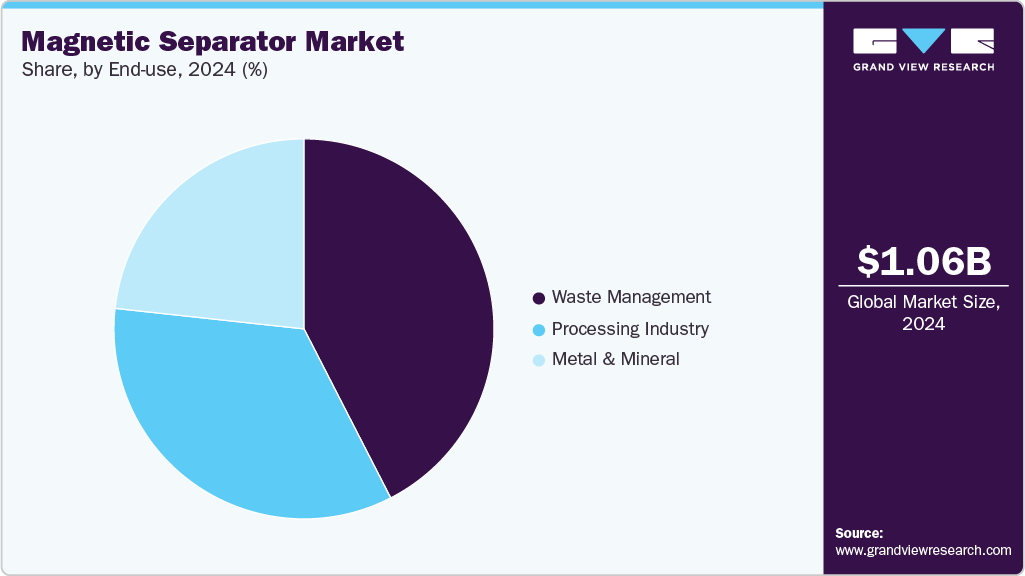

The waste management sector dominates the magnetic separator market and accounted for a share of 42.5% in 2024 as these systems are crucial for efficient ferrous material recovery from municipal solid waste and recycling streams. Magnetic separators help reduce landfill load and recover valuable metals for reuse. High adoption in recycling plants and scrap processing facilities reinforces their market leadership. Increasing environmental regulations and sustainability initiatives further drive demand in this segment.

The processing industry is witnessing significant growth in magnetic separator adoption due to the need for high-purity materials in mineral, chemical, and food processing operations. Magnetic separators enhance product quality by removing metal contaminants efficiently. Rising industrialization and the demand for advanced material handling solutions boost this segment. Continuous innovation in automated and high-precision separators supports its rapid expansion globally.

Regional Insights

North America Magnetic Separator Market Trends

North America growing at a significant CAGR of 5.2% in the magnetic separator market, driven by mining, recycling, and food processing industries increasingly adopt advanced separation technologies. Technological innovation and automation in separators enhance operational efficiency. Strong focus on environmental compliance and resource recovery boosts adoption. The presence of major market players and steady industrial demand supports regional expansion.

U.S. Magnetic Separator Market Trends

The U.S. dominates the North American magnetic separator market due to its advanced mining, recycling, and industrial sectors. High adoption of automated and high-precision separators enhances operational efficiency across industries. Strong environmental regulations drive the need for efficient metal recovery and waste management solutions. Continuous technological innovation and the presence of leading manufacturers reinforce the U.S. market leadership.

Canada is experiencing growth in the magnetic separator market, driven by expanding mining operations and mineral processing activities. Increasing focus on sustainable resource management and recycling initiatives boosts adoption. Demand for energy-efficient and high-recovery separators supports market expansion. Strategic investments and collaborations with global technology providers further strengthen regional growth.

Europe Magnetic Separator Market Trends

Europe is witnessing significant growth driven by stringent environmental regulations and high adoption of sustainable waste management practices. The recycling and metal processing industries increasingly rely on magnetic separators for efficient operations. Investments in technological upgrades and energy-efficient solutions further propel the market. Growing awareness of resource recovery and industrial automation strengthens regional demand.

Germany dominates the European magnetic separator market due to its strong industrial base, advanced recycling infrastructure, and high adoption of automated separation technologies. The country’s strict environmental regulations encourage efficient metal recovery and waste management solutions. Leading manufacturers and continuous technological innovations further strengthen its market position. High demand from the steel, automotive, and chemical industries supports sustained growth.

The UK is experiencing growth in the magnetic separator market driven by expanding recycling initiatives and industrial processing requirements. Increasing focus on sustainability and resource recovery fuels adoption across multiple sectors. Technological advancements, such as high-intensity and sensor-based separators, enhance operational efficiency. Collaboration with global suppliers and ongoing industrial investments further promote regional market expansion.

Asia Pacific Magnetic Separator Market Trends

Asia Pacific is the dominating region and accounted for the share of 43.8% in the global magnetic separator market, fueled by rapid industrialization, extensive mining activities, and growing recycling initiatives in countries such as China and India. The region benefits from a large base of manufacturers and suppliers offering advanced magnetic separation solutions. High demand from the steel, mineral processing, and electronics industries drives market growth. Favorable government policies and investments in sustainable technologies further reinforce their leading position.

China dominates the Asia Pacific magnetic separator market due to its extensive mining activities, large-scale industrial operations, and strong manufacturing base. High demand from the steel, mineral processing, and electronics sectors drives adoption of advanced magnetic separation technologies. Government initiatives promoting recycling and sustainable industrial practices further support market growth. Continuous investment in R&D and technological upgrades strengthens China’s leading position.

India is experiencing significant growth in the magnetic separator market, driven by rapid industrialization and expanding mining and recycling activities. Rising demand for high-purity materials in steel, mineral, and chemical processing boosts adoption. Focus on sustainable resource management and infrastructure development encourages investment in efficient separators. Increasing collaborations with global technology providers further accelerate regional market expansion.

Middle East & Africa Magnetic Separator Market Trends

The Middle East and Africa are experiencing gradual growth in magnetic separator adoption, primarily driven by mining, metal processing, and recycling industries. Rising investment in industrial infrastructure and resource recovery initiatives encourages market expansion. Demand for high-efficiency separators to optimize operations is increasing. Regional growth is further supported by partnerships with global suppliers and technology providers.

Saudi Arabia is witnessing growth in the magnetic separator market due to expanding mining, metal processing, and recycling industries. Investments in industrial infrastructure and modernization of mineral processing plants drive demand. The focus on resource efficiency and sustainable operations encourages adoption of advanced magnetic separation technologies. Partnerships with global suppliers and technology providers further support market expansion in the region.

Latin America Magnetic Separator Market Trends

Latin America is emerging as a growing market due to expanding mining and mineral processing activities in countries like Brazil and Chile. Increasing infrastructure development and industrialization fuel demand for magnetic separation solutions. The region is adopting modern, efficient separators to enhance metal recovery and reduce operational costs. Government initiatives to promote sustainable mining practices also support market growth.

Brazil dominates the Latin American magnetic separator market due to its extensive mining and mineral processing activities, particularly in iron ore and other metals. High demand from the steel and recycling industries drives adoption of efficient magnetic separation solutions. Government initiatives to promote sustainable mining practices further support market growth. Continuous investment in advanced technologies and industrial infrastructure reinforces Brazil’s leading position in the region.

Key Magnetic Separator Company Insights

Some of the key players operating in the market include Eriez Manufacturing Co., Nippon Magnetics Inc., LONGi Magnet Co., Ltd.

- Eriez Manufacturing Co. specializes in magnetic separation, metal detection, and material handling solutions tailored for industrial applications. The company is recognized for its high-intensity magnetic separators and innovative lifting magnets that improve efficiency in mining and recycling operations. Eriez emphasizes custom-engineered solutions to meet the specific needs of clients across diverse industries. Its products are designed for durability, ease of maintenance, and optimized recovery rates. Continuous investment in R&D ensures Eriez stays at the forefront of separation technology innovation.

- Nippon Magnetics Inc. focuses on the design and manufacture of permanent magnets, electromagnets, and magnetic assemblies for industrial use. The company’s products are widely employed in material separation, automation systems, and precision handling applications. Nippon Magnetics prioritizes high-quality engineering to enhance magnetic performance and operational reliability. Its solutions cater to sectors such as electronics, recycling, and metal processing, optimizing both efficiency and safety. Ongoing technological advancements and customization capabilities strengthen the company’s competitive position globally.

Key Magnetic Separator Companies:

The following are the leading companies in the magnetic separator market. These companies collectively hold the largest market share and dictate industry trends.

- Eriez Manufacturing Co.

- Nippon Magnetics Inc.

- LONGi Magnet Co., Ltd.

- Metso Corporation

- Outotec Oyj

- Noritake Co., Limited

- A AND A MAGNETICS, INC.

- SLon Magnetic Separator Ltd.

- KANETEC CO., LTD

- Shandong Huate Magnet Technology Co.

- Multotec (Pty) Ltd.

- STEINERT GmbH

- Sesotec GmbH

- Douglas Manufacturing Co., Inc.

- Permanent Magnets Ltd

Recent Developments

-

In October 2025, Eriez has launched BuyEriez.com, an online platform for North American customers to purchase in-stock magnetic separators and material handling equipment. The site offers magnetic tubes, plates, grates, traps, and lift magnets for industries like food processing and packaging. Customers can check inventory, view pricing, and complete secure purchases easily. This platform complements traditional sales channels while providing quick access to ready-to-ship products.

-

In August 2025, LONGi Magnet Co., Ltd. showcased advanced mining solutions at the 2025 Mining Science and Technology Conference in Wuhan. The company highlighted its LCTC wet magnetic separator, LCGJ dry separator, and LJC magnetic suspension concentrator for efficient iron ore processing. LONGi also presented X-ray-based sorting systems and an online slurry analyzer for real-time mineral detection. These innovations support cost-effective and automated mining operations.

Global Magnetic Separator Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 1,112.5 million

Revenue forecast in 2033

USD 1,642.5 million

Growth rate

CAGR of 5.0% from 2025 to 2033

Historical data

2021 - 2023

Forecast period

2025 - 2033

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2033

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, material type, magnet type, end use, and region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Spain; Italy; China; Japan; India; Australia; South Korea; Brazil; Argentina; Saudi Arabia; South Africa; UAE

Key companies profiled

Eriez Manufacturing Co.; Nippon Magnetics Inc.; LONGi Magnet Co., Ltd.; Metso Corporation; Outotec Oyj; Noritake Co.; Limited; A & A Magnetics, Inc.; SLon Magnetic Separator Ltd.; KANETEC CO., LTD; Shandong Huate Magnet Technology Co., Ltd.; Multotec (Pty) Ltd.; STEINERT GmbH; Sesotec GmbH; Douglas Manufacturing Co., Inc.; Permanent Magnets Ltd.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Magnetic Separator Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2033. For this study, Grand View Research has segmented the global magnetic separator market report based on product, material type, magnet type, end use, and region.

-

Product Outlook (Revenue, USD Million, 2021 - 2033)

-

Magnetic Drum Separator

-

Magnetic Roller Separator

-

Overband/Cross Belt Separator

-

Magnetic Pulley Separator

-

Others

-

-

Material Type Outlook (Revenue, USD Million, 2021 - 2033)

-

Wet

-

Dry

-

-

Magnet Type Outlook (Revenue, USD Million, 2021 - 2033)

-

Electromagnets

-

Permanent Magnet

-

-

End Use Outlook (Revenue, USD Million, 2021 - 2033)

-

Waste Management

-

Processing Industry

-

Metal & Mineral

-

-

Regional Outlook (Revenue, USD Million, 2021 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

France

-

Italy

-

Spain

-

UK

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East and Africa

-

Saudi Arabia

-

UAE

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global magnetic separator market size was estimated at USD 1,067.6 million in 2024 and is expected to be USD 1,112.5 million in 2025.

b. The global magnetic separator market, in terms of revenue, is expected to grow at a compound annual growth rate of 5.0% from 2025 to 2033 to reach USD 1,642.5 million by 2033.

b. Electromagnets dominate the magnetic separator market and accounted for a share of 58.7% in 2024 due to their adjustable magnetic strength and suitability for large-scale industrial applications. They are widely used in mining, steel, and recycling industries where precise control over separation is required. The ability to handle high volumes and recover valuable metals efficiently reinforces their preference.

b. Some of the key players operating in the global magnetic separator market include Eriez Manufacturing Co., Nippon Magnetics Inc., LONGi Magnet Co., Ltd., Metso Corporation, Outotec Oyj, Noritake Co., Limited, A & A Magnetics, Inc., SLon Magnetic Separator Ltd., KANETEC CO., LTD, Shandong Huate Magnet Technology Co., Ltd., Multotec (Pty) Ltd., STEINERT GmbH, Sesotec GmbH, Douglas Manufacturing Co., Inc., Permanent Magnets Ltd.

b. The global magnetic separator market is driven by the growing need for efficient mining and mineral processing, which enhances metal recovery and operational efficiency. Rising focus on recycling and sustainable waste management further boosts demand for magnetic separation solutions.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.