- Home

- »

- Petrochemicals

- »

-

Netherlands Metalworking Fluids Market Size Report, 2030GVR Report cover

![Netherlands Metalworking Fluids Market Size, Share & Trends Report]()

Netherlands Metalworking Fluids Market (2023 - 2030) Size, Share & Trends Analysis Report By Product (Mineral, Synthetic, Bio-based), By Application, By End-use, By Industrial End-use, And Segment Forecasts

- Report ID: GVR-4-68040-088-8

- Number of Report Pages: 118

- Format: PDF

- Historical Range: 2018 - 2021

- Forecast Period: 2023 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Market Size & Trends

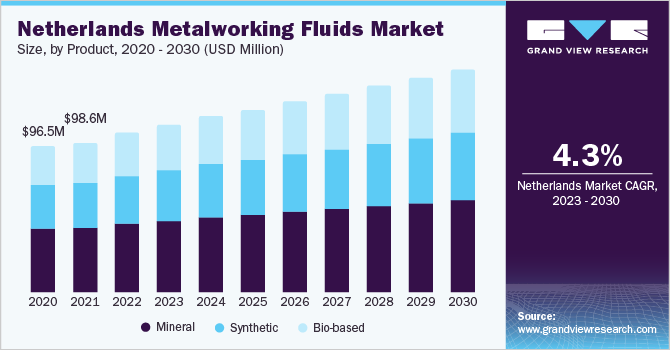

The Netherlands metalworking fluids market size was valued at USD 105.42 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. The increasing application of these products in various application industries such as metalworking, metal fabrication, industrial equipment manufacturing, and manufacturing transportation equipment is projected to have a positive impact on the growth. Key players include VALVOLINE, ExxonMobil Corporation, Perstorp, Kuwait Corporation, Matrix Specialty Lubricants, CIMCOOL EUROPE, FUCHS, Motul, and Quaker Chemical Corporation, among others. These companies are involved in rapid research & development, product portfolio enhancement, geographical expansion, partnerships, and mergers & acquisitions to gain a competitive edge in the market space.

According to the Centers for Disease Control and Prevention (CDC), metalworking fluids (MWFs) are employed in industrial machining and grinding operations to decrease heat and friction while also eliminating metal particles. Furthermore, according to Canadian Center for Occupational Health and Safety (CCOHS), these lubricants encompass various oils and liquids utilized for cooling and lubricating metal workpieces during machining, grinding, milling, and similar processes.

These oils serve to diminish heat and friction between the cutting tool and the workpiece, thereby preventing burning and smoking. In addition, MWFs aid in enhancing the equipment’s quality by effectively eliminating fines, chips, and swarfs (swarfs refer to the tiny metal pieces removed from a workpiece by a cutting tool) from both the tool and the surface of the workpiece.

They are employed in various applications, including metal fabrication and metalworking activities. According to Atradius N.V., despite contributing only around 1% to the Dutch GDP, the steel and metals sector holds significant importance as a primary provider for the construction, automotive, and machinery industries. The success of the sector relies heavily on the performance of the domestic construction sector.

In addition, there are multiple companies engaged in metalworking and fabrication activities such as HVL Metaal & Techniek, Machinefabriek Geurtsen, VDS Rotterdam B.V., GB Steel Group, and Sheet Metal Connect, among others. To sum up, the presence of such large-scale metal fabricators and companies in the Netherlands may have a positive impact on the metalworking fluids market as it paves the way for increasing penetration of the product in multiple end-use industries.

According to UNIL, metalworking fluids consist of either pure oils, water, or oil-based products, each possessing its unique properties and components. Different types of products exhibit varying characteristics and compositions. These oils encompass a range of 10 to 30 different ingredients. It is worth noting that certain formulations may include irritating substances or allergens. Broadly, the raw materials used can be classified under three sections: base oils, emulsifiers, and additives.

Product Insights

Mineral-based products dominated the market with a revenue share of 42.39% in 2022. This is attributable to the wide range of benefits offered by the product such as their lubricating, cooling, and protective properties that make them ideal for numerous application areas. In addition, one of the key advantages of mineral oil-based products is their cost efficiency. They are considered one of the most economical options in terms of production cost. This cost-effectiveness makes them particularly attractive to small- and medium-scale producers who are conscious of their budget constraints.

Synthetic-based products are an important category of oils used in various metalworking processes. These fluids, specially formulated from synthetic base oils, offer distinct advantages over other types of metalworking fluids. Synthetic-based metalworking fluids are known for their superior performance compared to mineral oil-based fluids. They offer excellent lubrication properties, reducing friction and wear between the cutting tool and workpiece. This results in improved tool life, better surface finish, and increased machining accuracy.

Bio-based metalworking fluids refer to fluids used in metalworking processes that are derived from renewable sources such as vegetable oils, esters, or other bio-based compounds. These fluids offer a more sustainable and environmentally friendly alternative to traditional metalworking fluids. As a result, governments and regulatory bodies worldwide are promoting the use of bio-based products including metalworking fluids.

Application Insights

Neat cutting oils application dominated the market with a revenue share of 46.82% in 2022. This is attributable to the increasing usage of such oils due to their ability to reduce friction between the cutting tool and workpiece, minimizing tool wear and extending tool life. Furthermore, these oils have excellent cooling properties, dissipating heat generated by the cutting process.

Water-based cutting fluids are primarily composed of water, with various additives and chemicals incorporated to enhance their performance. These additives can include lubricants, corrosion inhibitors, biocides, emulsifiers, and pH stabilizers. According to HAI LU JYA HE CO., as of 2023, water-based cutting oils are widely preferred as cutting fluids due to their significant role in machining and grinding processes, offering numerous advantages.

Corrosion preventive oils, also known as rust preventive oils or anti-corrosion oils, are specialized lubricants designed to protect metal surfaces from corrosion. These oils form a thin, protective film on the metal surface, acting as a barrier against moisture, oxygen, and other corrosive elements. They are commonly used in various industries, including automotive, manufacturing, and transportation, to prevent rust and corrosion on metal parts and components.

End-use Insights

Machinery end-use dominated the market with a revenue share of 39.49% in 2022. This is attributable to the rising usage of metalworking fluids in various heavy industrial machinery such as mining equipment, manufacturing machines, and industrial equipment, devices, and parts.

Metalworking fluids are extensively used in metal fabrication processes to enhance performance, improve efficiency, and prolong tool life. MWFs are designed for use in cutting, grinding, drilling, milling, and turning operations. They provide several functions that contribute to the overall metalworking process. These attributes contribute to their widespread adoption in the metalworking industry in recent years. Moreover, the increasing demand for metal fabrication is expected to be propelled by the expansion of the construction, electrical & power, and agriculture industries. Given the intricacy involved in manufacturing diverse components, the utilization of metalworking fluids becomes necessary.

Metalworking fluids (MWFs) play a crucial role in the production of transportation equipment such as automobiles, aircraft, ships, and trains. They are used in various manufacturing processes throughout the production cycle. MWFs are extensively used in machining operations like milling, turning, drilling, and grinding during the fabrication of transportation equipment components. They provide lubrication to reduce friction and heat generation, improving tool life and surface finish. MWFs also aid in chip evacuation, ensuring efficient and clean cutting.

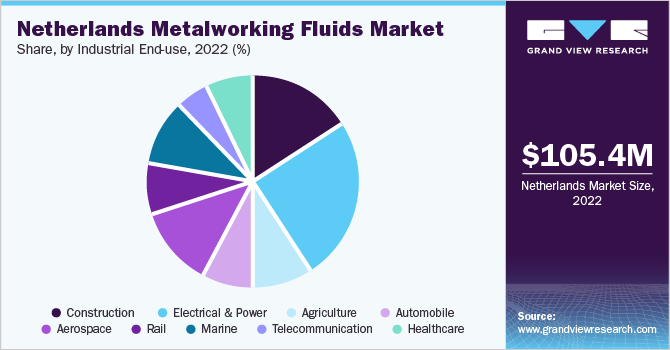

Industrial End-use Insights

Electric & power industrial end-use dominated the market with a revenue share of 25.21% in 2022. This is attributable to the rising applications of various critical metals to generate electricity. This in turn, is expected to boost the demand for metalworking fluids for the maintenance and production of such metal equipment that generates renewable as well as traditional electricity through heavy equipment like generators, alternators, and capacitors.

The demand for construction equipment is expected to showcase growth over the forecast period. This is because of the increase in spending from the government on public infrastructure through the National Growth Fund. The Netherlands construction equipment market is anticipated to receive a boost from the government's initiatives to stimulate investments in the development of public infrastructure. To sum up, the growth in the construction sector due to the rise in government investments in the sector coupled with increasing demand for construction equipment is anticipated to have a positive impact on the metalworking fluids market in the Netherlands.

The aviation industry imposes rigorous standards on components, necessitating precision, advanced technology, stability, and weight reduction. These demanding requirements extend to the production of parts, encompassing materials like aluminum, titanium, and composites, as well as the machinery and tools involved in machining processes. Maintaining a smooth manufacturing process is of utmost importance. As a result, there emerges a need for specially developed and approved metal working fluids (MWF) for the machining of aviation components.

Key Companies & Market Share Insights

The Netherlands metalworking fluids market is highly competitive. Key players focus on broadening their product portfolio, new product launches, investments in R&D, and technological developments. In addition, various partnerships and distribution agreements are undertaken by these manufacturing companies to meet the rising demand for the product in new geographical markets. For instance, in January 2023, Univar Solutions B.V. entered a distribution agreement with Graphics Services Ltd. for their products such as inks, rust preventive oils, coatings, lubricants, and metalworking fluids in Europe.

Moreover, companies are investing in R&D activities to develop new products with higher quality and purity as well as the development of new technology. This gives the manufacturers a competitive advantage over other companies. For example, in October 2019, Castrol launched SmartControl, a system that provides in-machine, automatic, real-time management and monitoring of metalworking fluids. This technology has been developed in collaboration with Tiefenbach, a German control systems expert. Some prominent players in the Netherlands metalworking fluids market include:

-

VALVOLINE

-

ExxonMobil Corporation

-

FUCHS

-

Perstorp

-

CIMCOOL EUROPE

-

Motul

-

Aimol

-

Quaker Chemical Corporation

-

Matrix Specialty Lubricants

-

Kuwait Petroleum

Netherlands Metalworking Fluids Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 110.85 million

Revenue forecast in 2030

USD 147.72 million

Growth rate

CAGR of 4.3% from 2023 to 2030

Base year for estimation

2022

Historical data

2018 - 2021

Forecast period

2023 - 2030

Quantitative units

Revenue in USD million, volume in kilotons, and CAGR from 2023 to 2030

Report coverage

Revenue forecast, volume forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, application, end-use, industrial end-use

Country scope

The Netherlands

Key companies profiled

VALVOLINE; ExxonMobil Corporation; FUCHS; Perstorp; CIMCOOL EUROPE; Motul; Aimol; Quaker Chemical Corporation; Matrix Specialty Lubricants; Kuwait Petroleum

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Netherlands Metalworking Fluids Market Report Segmentation

This report forecasts revenue and volume growth at the country level and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the Netherlands metalworking fluids market report based on product, applications, end-use, and industrial end-use:

-

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Mineral

-

Synthetic

-

Bio-based

-

-

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Neat Cutting Oils

-

Water Cutting Oils

-

Corrosion Preventive Oils

-

Other Applications

-

-

End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Metal Fabrication

-

Transportation Equipment

-

Machinery

-

Other End-uses

-

-

Industrial End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Construction

-

Electrical & Power

-

Agriculture

-

Automobile

-

Aerospace

-

Rail

-

Marine

-

Telecommunication

-

Healthcare

-

Frequently Asked Questions About This Report

b. Mineral Based Metalworking Fluids dominated the Netherlands Metalworking Fluids Market with a share of 42.39% in 2022. This is attributable to the increasing penetration of the product in numerous industrial applications owing to its advantageous such as high versatility and lower cost.

b. Some key players operating in the Netherlands Metalworking Fluids Market include Valvoline, ExxonMobil Corporation, FUCHS, CIMCOOL EUROPE, Motul, Aimol, and Quaker Chemical Corporation.

b. Key factors that are driving the market include increasing product penetration in aerospace industry, and its rising applications in railway, metal fabrication, and heavy equipment manufacturing.

b. The Netherlands Metalworking Fluids Market was estimated at USD 105.42 Million in 2022 and is expected to reach USD 110.85 Million in 2023.

b. The Netherlands Metalworking Fluids Market is expected to grow at a compound annual growth rate of 4.3% from 2023 to 2030 to reach USD 147.72 Million by 2030.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.