- Home

- »

- Advanced Interior Materials

- »

-

U.S. Industrial Boiler Market Size, Industry Report, 2030GVR Report cover

![U.S. Industrial Boiler Market Size, Share & Trends Report]()

U.S. Industrial Boiler Market (2025 - 2030) Size, Share & Trends Analysis Report By Fuel (Fossil, Oil & Gas, Biomass), By Capacity, By Application (Chemicals & Petrochemicals, Metals & Mining), And Segment Forecasts

- Report ID: GVR-4-68039-048-0

- Number of Report Pages: 80

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

U.S. Industrial Boiler Market Size & Trends

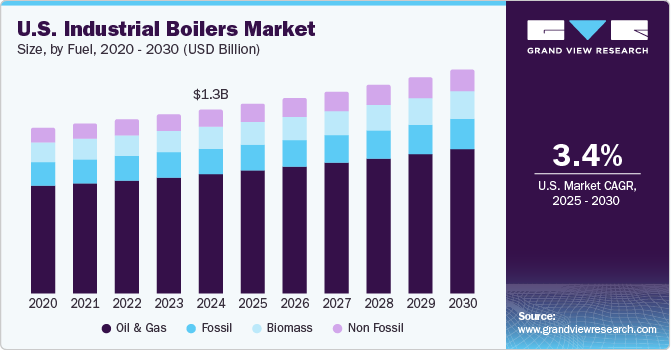

The U.S. industrial boiler market size was valued at USD 1.30 billion in 2024 and is expected to grow at a CAGR of 3.4% from 2025 to 2030. This growth is attributed to the increasing industrialization and substantial investments in manufacturing facilities are significantly boosting demand. In addition, the push for energy efficiency and stringent environmental regulations are prompting industries to replace outdated boilers with modern, efficient systems. Furthermore, the rising focus on reducing carbon emissions further supports this trend. Moreover, the food and beverage sector's expansion, alongside advancements in boiler technology, is enhancing the overall market landscape.

An industrial boiler is a closed vessel designed to heat water or produce steam under pressure, serving various industrial applications. These boilers utilize fuels such as oil, coal, or natural gas to generate heat, which is transferred to water, resulting in steam or hot water for heating, power generation, and other uses. They are essential in manufacturing and food processing industries, as they power turbines for electricity, provide heat for processes, and ensure sanitation through sterilization.

The demand for industrial boilers is surging due to rapid industrialization in developing countries such as the U.S. This growth is driven by increased manufacturing activities that require efficient heating solutions. Furthermore, there is a rising focus on energy efficiency and emission reduction, with stringent environmental regulations pushing industries to adopt modern boiler systems that enhance energy efficiency and lower carbon footprints.

Moreover, the food and beverage sector significantly contributes to the industrial boiler market. As global food production needs to expand to meet population demands, more food processing facilities are emerging, relying heavily on industrial boilers for various operations. These boilers are crucial for cooking, sterilizing, and processing food products, thereby playing a vital role in ensuring food safety and quality while supporting the industry's growth.

Fuel Insights

The oil and gas segment held the dominant position in the market and accounted for the largest revenue share of 64.9% in 2024. This growth is attributed to natural gas's high availability and competitive pricing, making it the preferred fuel for many industrial applications, leading to increased adoption of gas-fired boilers. Furthermore, stringent environmental regulations encourage industries to transition from coal and oil to cleaner-burning natural gas, producing lower emissions. This shift meets regulatory requirements and enhances operational efficiency, further propelling market growth.

The non-fossil fuel segment is expected to grow at a CAGR of 4.3% over the forecast period, owing to rising environmental concerns and a strong push for sustainability. Industries are increasingly adopting biomass and other renewable energy sources as alternatives to traditional fossil fuels. Government incentives and policies promoting renewable energy usage are also driving this trend. Furthermore, advancements in boiler technology that allow for efficient use of non-fossil fuels contribute to the segment's growth as businesses seek to reduce their carbon footprints and comply with stricter emissions standards.

Capacity Insights

The small capacity segment led the market and accounted for the largest revenue share of 38.2% in 2024. This growth is attributed to the increasing demand for efficient and flexible heating solutions in various industries. Small boilers are particularly favored in sectors such as food and beverage, where they provide essential steam for processes during off-peak seasons. In addition, their compact size makes them ideal for facilities with limited space, allowing for easy installation and operation. Furthermore, the growing trend toward automation and energy efficiency encourages manufacturers to invest in small boilers that can effectively meet fluctuating steam requirements while minimizing energy consumption.

The large capacity segment is expected to grow at a CAGR of 3.7% from 2025 to 2030, driven by its critical role in heavy industries such as petrochemicals, pulp and paper, and energy production. These sectors require substantial steam output for various processes, including heating, fractionation, and pressure control. In addition, the increasing focus on operational efficiency and sustainability drives industries to upgrade to larger, more efficient boilers that comply with stringent environmental regulations. Furthermore, ongoing investments in infrastructure and industrial expansion contribute to the rising demand for large-capacity boilers as companies seek reliable solutions to support their extensive production needs.

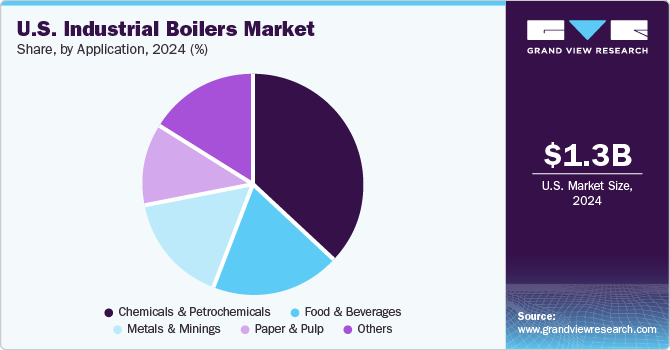

Application Insights

The chemical and petrochemicals application segment dominated the market and accounted for the largest revenue share of 36.5% in 2024. This growth is attributed to these industries' increasing demand for efficient heating solutions. As the chemical sector expands, reliable steam generation for processes such as distillation and heating becomes critical. Furthermore, stringent environmental regulations push companies to adopt modern, low-emission boilers that enhance operational efficiency while reducing their carbon footprint. This combination of industrial growth and regulatory compliance drives significant investment in industrial boiler systems.

The food and beverage application segment is expected to grow at a CAGR of 4.0% over the forecast period, owing to the rising demand for processed food and beverages, which necessitates efficient heating solutions. Industrial boilers play a vital role in various processes, including cooking, pasteurization, and sterilization, ensuring product quality and safety. In addition, the sector's expansion is further supported by consumer preferences for high-quality and safe food products, prompting manufacturers to invest in advanced boiler technologies that improve energy efficiency and comply with health regulations.

Key U.S. Industrial Boiler Company Insights

Some of the key players in the market include IHI Corporation, Forbes Marshall, Hurst Boiler & Welding Company, Inc., and others. These companies adopt various strategies, such as new product launches focused on developing advanced, energy-efficient boiler systems that meet evolving regulatory standards and customer demands. Mergers and acquisitions are utilized to expand market presence and consolidate resources, while strategic collaborations and agreements facilitate technology sharing and innovation. Furthermore, companies are exploring geographical expansion to tap into emerging markets, ensuring they remain responsive to industry trends and customer needs.

-

Mitsubishi Heavy Industries, Ltd. produces a wide range of boilers, including oil and gas-fired, grate-fired, and waste heat recovery boilers, catering to various industries such as chemical processing, steel production, and power generation. The company operates primarily in the energy and industrial sectors, providing high-performance boiler solutions that enhance efficiency and sustainability while meeting stringent environmental standards.

-

IHI Corporation designs and produces a variety of boiler systems tailored to meet diverse industrial needs, emphasizing high efficiency and reliability. The company operates mainly in the energy sector, focusing on advanced technologies that ensure compliance with global emissions standards. Their innovative approach supports industries in achieving operational excellence while addressing environmental sustainability challenges through state-of-the-art boiler solutions.

Key U.S. Industrial Boiler Companies:

- Babcock & Wilcox Enterprises, Inc.

- Mitsubishi Heavy Industries, Ltd.

- IHI Corporation

- Forbes Marshall

- Daikin Industries Ltd.

- Hurst Boiler & Welding Company, Inc.

- Powermaster

- Rentech Boilers

- Sioux Corporation

- Superior Boiler Works

- The Fulton Companies

- Unilux Advanced Manufacturing

- Vapor Power International

- Victory Energy Operations

Recent Developments

-

In May 2024, Daikin Industries, Ltd. announced a strategic partnership with Miura Co., Ltd., a leading industrial boiler manufacturer. Daikin will acquire 4.67% of Miura's shares, while Miura will take a 49% stake in Daikin Applied Systems. This collaboration aims to provide comprehensive solutions for factories, integrating air conditioning, steam boilers, and water treatment systems to enhance energy efficiency and reduce CO2 emissions. Both companies are committed to achieving carbon neutrality in industrial operations through innovative technologies and services.

-

In February 2024, Babcock Wanson Group announced its acquisition of VKK Group, a leading German company specializing in industrial boiler technology. This strategic move aims to strengthen Babcock Wanson's presence in Germany, a key market for industrial boilers. VKK Group, known for its expertise in designing and manufacturing high-power boilers, will enhance Babcock Wanson's capabilities in providing energy-efficient solutions. The acquisition is expected to facilitate the integration of VKK's advanced technologies and support ongoing decarbonization efforts within the industrial sector.

U.S. Industrial Boiler Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 1.34 billion

Revenue forecast in 2030

USD 1.59 billion

Growth Rate

CAGR of 3.4% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Revenue in USD Million, and CAGR from 2025 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Fuel, capacity, and application.

Country scope

U.S.

Key companies profiled

Babcock & Wilcox Enterprises, Inc.; Daikin Industries Ltd.; Mitsubishi Heavy Industries, Ltd.; IHI Corporation; Forbes Marshall; Hurst Boiler & Welding Company, Inc.; Powermaster; Rentech Boilers; Sioux Corporation; Superior Boiler Works; The Fulton Companies; Unilux Advanced Manufacturing; Vapor Power International; Victory Energy Operations.

Customization scope

Free report customization (equivalent to 8 analyst working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

U.S. Industrial Boiler Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and analyzes the latest industry trends in each sub-segment from 2018 to 2030. For this study, Grand View Research has segmented the U.S. industrial boiler market report based on fuel, capacity, and application.

-

Fuel Outlook (Revenue, USD Million, 2018 - 2030)

-

Oil & Gas

-

Fossil

-

Non Fossil

-

Biomass

-

-

Capacity Outlook (Revenue, USD Million, 2018 - 2030)

-

Small

-

Medium

-

Large

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Chemicals & Petrochemicals

-

Small

-

Medium

-

Large

-

-

Paper & Pulp

-

Small

-

Medium

-

Large

-

-

Food & Beverages

-

Small

-

Medium

-

Large

-

-

Metals & Minings

-

Small

-

Medium

-

Large

-

-

Others

-

Small

-

Medium

-

Large

-

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.