- Home

- »

- Market Trend Reports

- »

-

3D And 4D Printed Dental Implants: Advancements And Market Trends

Executive Summary

The 3D and 4D-printed dental implants transform restorative dentistry by enabling patient-specific, high-precision implants with enhanced osseointegration and mechanical performance. Key drivers include the rising demand for personalized treatments, advancements in biocompatible materials, and integration with digital workflows. Emerging trends focus on stimuli-responsive 4D implants, nano-scale surface modifications, and chairside additive manufacturing for minimally invasive, adaptive dental solutions.

Technological Advancements

Market Drivers

- Increasing demand for personalized and patient-specific implants

The increasing demand for personalized and patient-specific implants drives the growth of 3D and 4D-printed dental implants because traditional implants are standardized and often require adjustments to fit individual anatomical variations. With 3D printing, dental implants can be custom designed to match a patient’s exact jawbone structure, tooth position, and occlusion, improving fit, comfort, and osseointegration.

4D printing further enhances this by enabling stimuli-responsive implants that adapt to changes in the oral environment over time, such as swelling, load distribution, or tissue growth. This level of customization reduces surgical complications, shortens recovery time, and increases treatment success, making additive manufacturing technologies highly attractive in modern dentistry. For instance, in June 2024, the National Center for Biotechnology Information conducted a study on the oral health condition of individuals undergoing 3D-printed customized dental implantation, highlighting the clinical benefits of tailored implant solutions.

3D-printed implant patient characteristics (2021-2023)

Gender

Age (Y)

Tooth Position

Etiology

Root Length (mm)

Mesiodistal Diameter (mm)

Buccolingual Diameter (mm)

1

M

31

15

Residual Crown

9.5

3.5

8.8

2

F

33

35

Tooth Split

9.7

3.5

5.5

3

F

37

45

Residual Root

10.9

3.8

5.9

4

F

29

25

Residual Crown

11.3

4.0

7.3

5

F

33

24

Residual Crown

8.0

3.7

7.4

6

F

30

15

Residual Root

8.6

3.4

7.7

7

F

50

12

Residual Root

7.9

4.4

5.7

8

F

56

25

Residual Root

8.5

3.4

7.8

9

M

39

25

Residual Root

9.5

3.8

8.5

10

F

62

45

Residual Crown

7.8

4.0

5.9

11

F

23

15

Residual Crown

12.0

6.3

13.0

12

F

51

22

Residual Crown

9.9

4.0

5.8

13

F

30

15

Residual Crown

10.6

4.2

7.9

14

M

39

35

Residual Root

10.5

4.1

6.4

15

M

38

25

Tooth Split

13.5

4.5

9.1

16

M

28

35

Residual Root

11.7

5.0

6.9

17

F

37

15

Residual Crown

9.0

4.3

8.2

Source: NCBI, Primary Interviews, Grand View Research Analysis

Comparison between conventional dental implants and 3D-printed dental implants (2021-2023)

Feature

Conventional Dental Implants

3D-Printed Implants

Cost

16,000 RMB

8,000 RMB

Surgical time

20-40 min

10-20 min

Planning time

5-10 min

60-120 min

Bone graft

Often

Less

Bone loss

Yes

No

Complication

Less

Less

Number of visits

3-4 times

2 times

Treatment steps

Normal

Simplified

Surgical technical difficulty

Normal

Simplified

Scope of application

Wide

Narrow

Source: NCBI, Primary Interviews, Grand View Research Analysis

Clinical Trial Study

Study Title

Conditions

Interventions

Sponsor

Enrollment

Completion Date

“Comparative Study of Supra-Structure Materials in Full-Arch Implant Prosthetics: a Randomized Clinical Trial”

Edentulous

Mandible

Other: dental implant prosthesis

Misr University for Science and Technology

32

8/8/2025

Source: ClinicalTrials.gov

-

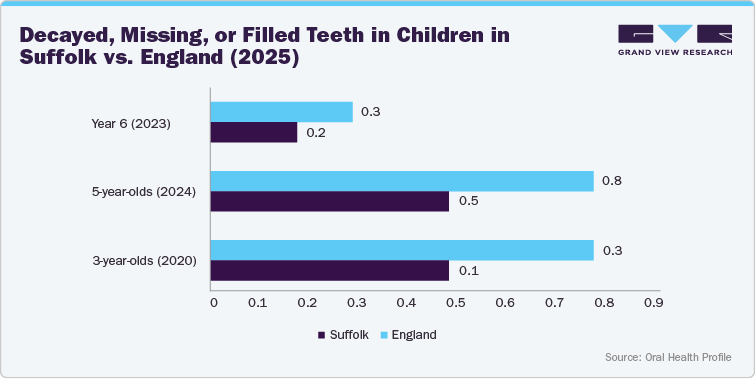

Growing prevalence of dental disorders and tooth loss

The growing prevalence of dental disorders and tooth loss drives the adoption of 3D and 4D-printed dental implants by increasing the need for effective, reliable, and personalized restorative solutions. Traditional implants may not adequately address complex cases such as severe bone loss or multiple missing teeth, whereas 3D printing allows for customized implant designs that match individual jaw anatomy. 4D printing further enhances treatment by enabling adaptive, stimuli-responsive implants that improve integration and long-term functionality, meeting the rising demand for precise and patient-specific dental care.

Competitive Scenario

Some of the key players operating in the 3D and 4D printed dental implants include:

Recent Developments

Some of the strategies undertaken by key industry players operating in the 3D and 4D printed dental implants market are mentioned below:

-

In July 2025, 3D Systems achieved a major milestone in digital dentistry with the full commercial release of its FDA-cleared NextDent Jetted Denture Solution in the U.S. market. This innovative system produces monolithic, multi-material dentures in a single printing process, offering durable, aesthetically pleasing, and patient-specific prosthetics. Powered by the NextDent 300 MultiJet 3D printer and specialized dental materials, it enables faster, cost-effective production without additional post-curing. The solution significantly enhances efficiency in denture fabrication and expands the capabilities of digital dentistry for dental professionals.

-

In May 2025, Objective3D made significant strides in dental technology by expanding the use of advanced 3D printing for customized dental implants. Their latest development enables the production of highly precise, patient-specific implants that enhance fit, comfort, and long-term outcomes. This innovation streamlines the implant fabrication process, reduces treatment time, and allows dental professionals to deliver more personalized and efficient care.

-

In September 2022, SINTX Technologies advanced its capabilities in 3D-printed medical implants by leveraging the unique properties of silicon nitride. Utilizing their FleX-SN PEEK composite, the company developed high-performance implant devices that offer exceptional biocompatibility, resulting in high rates of acceptance and long-term implant success. This innovation enables the creation of customized implants tailored to individual patient anatomies, enhancing both functionality and patient outcomes.

Share this report with your colleague or friend.

GET A FREE SAMPLE

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities.

Contact us now to get our best pricing.

![esomar icon]()

ESOMAR certified & member

![ISO]()

ISO Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

Client Testimonials

"The quality of research they have done for us has been excellent..."

ISO Certified