- Home

- »

- Advanced Interior Materials

- »

-

Spray Drying Equipment Market Size Industry Report, 2025GVR Report cover

![Spray Drying Equipment Market Size, Share & Trends Report]()

Spray Drying Equipment Market (2019 - 2025) Size, Share & Trends Analysis Report By Cycle (Open, Closed), By Product (Rotary, Nozzle Atomizer), By Stage (Single-Stage, Two-Stage), By Flow, By Application, And Segment Forecasts

- Report ID: GVR-3-68038-069-9

- Number of Report Pages: 101

- Format: PDF

- Historical Range: 2015 - 2017

- Forecast Period: 2019 - 2025

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Report Overview

The global spray drying equipment market size was valued at USD 4.63 billion in 2018 and is projected to expand at a CAGR of 6.8% from 2019 to 2025. Growing preference for functional and Ready-To-Eat (RTE) food products and focus of food processing companies on introducing products with enhanced shelf-life are expected to drive the market growth from 2019 to 2025. Rising product usage in the pharmaceutical and nutraceutical industries in the production of antibiotics, penicillin, enzymes, and whey proteins is also expected to drive the market over the forecast period.

Spray drying is the most common and easy drying process used for drying any liquid or semi-solid feed as compared to other industrial drying processes. It is also the most viable method to produce heat-sensitive products, such as milk powder, egg powder, and coffee powder. It helps in producing fine and granular dried powder particles, which can be used as flavoring agents in food products and juices and as fillings in bakery products.

Thus, spray dryers are being widely used in the food processing, dairy industry, pharmaceutical, nutraceuticals, and chemical industries. This is encouraging manufacturers to design and develop application-specific equipment that support different types of feedstock, such as a solution, paste, gel, slurry, suspension, and melt. All these factors bode well for the market growth. However,high installation and maintenance costs and lack of skilled engineers may restrain the market growth to some extent.

Moreover, high energy consumption and toxic gas emissions associated with these equipment are turning out to be the major concerns for manufacturers as well as consumers, particularly in the wake of the calls by various governments to ensure energy-efficient industrial operations to curb the pollution levels. Nevertheless, technological advances are allowing manufacturers to develop products that are energy-efficient and free from hazardous gases emissions, which will open significant growth opportunities for the market.

Product Insights

The nozzle atomizer segment held the largest market share of 41.2% of the global market in 2018 owing to the significant adoption of nozzle atomizer-based equipment to produce coarser and free-flowing powders. Moreover, nozzle atomizer dryers can also be used in conjunction with multiple nozzle installations to offer a wide range of flow rates. Thus, these are the ideal choice for applications that require optimum flow rates and involve the production of flexible particle sizes. On the other hand, rising need to reduce the moisture content while processing pharmaceutical products and to achieve an optimum quality and fine granular particles while processing food products are expected to trigger the adoption of fluidized dryers over the forecast period.

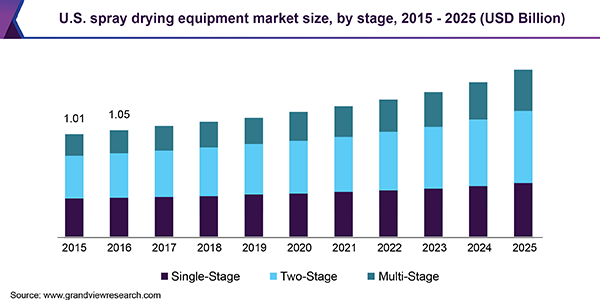

Stage Insights

The two-stage segment accounted for the largest market share of more than 40% in 2018 and is estimated to maintain the dominance in future. This can be attributed to increasing demand for these dryers across various industrial applications owing to lesser production costs without compromising the product quality. Two-stage dryers are usually used by medium- and large-scale industrial manufacturers owing to the benefits offered by these equipment, such as the ability to process varying volumes of feedstock.

However, the multi-stage product segment is expected to register the highest CAGR over the forecast period owing to their benefits, such as ability to control the drop in pressure between the first stage and final stage of the spray drying process instantaneously and to produce dust-free agglomerated products with optimum dispersibility. These benefits would particularly bolster its demand across large-scale food processing industries. Moreover, growing need to produce dried powders with high thermal efficiency in bulk quantities is also expected to drive the segment growth over the forecast period.

Cycle Insights

The open cycle segment accounted for the largest market share of more than 65% in 2018 and is likely to maintain the dominance in the years to come. It is the conventional drying equipment and is preferred for several applications owing to the numerous advantages, such as their ability to handle heat-resistive and heat-sensitive products, availability in all sizes and capacities, and low energy consumption.

However, some products, such as those dissolved or suspended in organic solvents, cannot be dried using a common open cycle dryer in the presence of atmospheric air, as such an attempt carries the risk of explosion. Hence, closed cycle spray dryers are preferred for drying specific products, such as carbide, dyestuffs, and pigments. Moreover, they leverage an inert gas, e.g. nitrogen, to annul the risk of an explosion and the subsequent fire. Due to all these factors, the closed cycle segment is estimated to expand at the maximum CAGR of 7.8% over the forecast period.

Flow Insights

The co-current segment held the largest market share of more than 55% in 2018 as the key companies launched a variety of these type of equipment for industrial, laboratory, and R&D applications. Co-current flow dryers are particularly preferred for processing heat-sensitive products owing to their ability to reduce the temperature of the drying air by vaporization of water instantaneously. Mixed flow is expected to be the fastest-growing segment over the forecast period. A mixed flow pattern offers better mixing capabilities and potentially delivers a supreme efficiency by combining the co-current and counter-current flow techniques. Hence, the application areas and subsequently the adoption of mixed flow dryers would continue to grow.

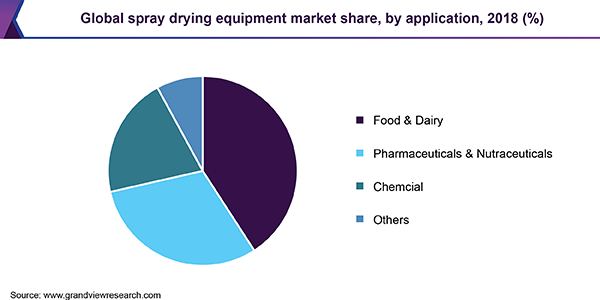

Application Insights

Food & dairy was the largest application segment in 2018 owing to a significant adoption of the equipment for producing infant products, egg powder, and coffee powder. Moreover, favourable decisions by the governments of emerging economies, such as India and China, to increase the Foreign Direct Investments (FDIs) limits for the food processing industry is encouraging companies of the dairy industry to install processing plants in these countries. This is expected to drive the segment growth.

The chemical segment is said to register the highest CAGR from 2019 to 2025 due to increasing product adoption in the chemical industry for spray drying polymers, resins, and other intermediates chemical products. Rising need to ensure compliance with the environmental and safety regulations for processing of products, such as flammable organic solvents, catalysts, and other chemical compounds, is also expected to drive the segment growth over the forecast period.

Regional Insights

North America accounted for the largest market share of more than 30% in 2018 due to quick adoption of new and emerging technologies by key companies to improve the overall efficiency and ensure optimum product quality. In addition, higher R&D capabilities across various industries, such as pharmaceutical and nutraceutical, in U.S. led to the increased adoption of these equipment. Asia Pacific is said to be the fastest-growing regional market at a CAGR of 8.1% from 2019 to 2025 on account of changing food preferences coupled with rising disposable income levels. Moreover, favorable regulations by some of the governments encouraging overseas investors to establish food & dairy production facilities in the region will propel the market.

Key Companies & Market Share Insights

Prominent players in the spray drying equipment market include GEA Group AG; G. Larsson Starch Technology AB; SPX FLOW, Inc.; Dedert Corporation; Shandong Tianli Drying Technology and Equipment Co., Ltd.; Hemraj Enterprises, New AVM Systech Pvt. Ltd.; BÜCHI Labortechnik AG; Yamato Scientific America, Inc.; Swenson Technology, Inc.; Tetra Pak International S.A.; Saka Engineering Systems Private Ltd.; Tetra Pak International S.A.; and Acmefil Engineering Systems Pvt. Ltd.

Key companies focus on expanding their geographical footprint in emerging economies. For instance, Dedert Corporation has commissioned a new food ingredient spray dryer in Indonesia. The new plant would increase the production capacity of food ingredient sweeteners required for infant formula to 4,000kg/h. The company has also installed an equipment at Archer Daniels Midland Company’s new plant in Tianjin, China. The new plant has a production capacity of 15,000 metric tons/year and would produce soluble dietary fiber.

Spray Drying Equipment Market Report Scope

Report Attribute

Details

Market size value in 2020

USD 5.12 billion

Revenue forecast in 2025

USD 7.20 billion

Growth Rate

CAGR of 6.8% from 2019 to 2025

Base year for estimation

2018

Historical data

2015 - 2017

Forecast period

2019 - 2025

Quantitative units

Revenue in USD billion and CAGR from 2019 to 2025

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, stage, cycle, flow, application, and region.

Regional scope

North America; Europe; Asia Pacific; South America; MEA

Country scope

U.S.; Canada; U.K.; Germany; France; Spain; Italy; China; India; Japan; South Korea, Australia; Brazil; and Argentina.

Key companies profiled

GEA Group AG; G. Larsson Starch Technology AB; SPX FLOW, Inc.; Dedert Corporation; Shandong Tianli Drying Technology and Equipment Co., Ltd.; Hemraj Enterprises, New AVM Systech Pvt. Ltd.; BÜCHI Labortechnik AG; Yamato Scientific America, Inc.; Swenson Technology, Inc.; Tetra Pak International S.A.; Saka Engineering Systems Private Ltd.; and Acmefil Engineering Systems Pvt. Ltd.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Segments Covered in the ReportThis report forecasts revenue and volume growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2015 to 2025. For the purpose of this study, Grand View Research has segmented the global spray drying equipment market report on the basis of product, stage, cycle, flow, application, and region:

-

Product Outlook (Revenue, USD Million, 2015 - 2025)

-

Rotary Atomizer

-

Nozzle Atomizer

-

Fluidized

-

Centrifugal

-

-

Stage Outlook (Revenue, USD Million, 2015 - 2025)

-

Single-Stage

-

Two-Stage

-

Multi-Stage

-

-

Cycle Outlook (Revenue, USD Million, 2015 - 2025)

-

Open

-

Closed

-

-

Flow Outlook (Revenue, USD Million, 2015 - 2025)

-

Co-Current

-

Counter-Current

-

Mixed Flow

-

-

Application Outlook (Revenue, USD Million, 2015 - 2025)

-

Food & Dairy

-

Pharmaceuticals & Nutraceuticals

-

Chemical

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2015 - 2025)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

U.K.

-

Germany

-

France

-

Spain

-

Italy

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

South America

-

Brazil

-

Argentina

-

-

MEA

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.