- Home

- »

- Specialty Glass, Ceramic & Fiber

- »

-

Sputtering Equipment Cathode Market Size, Industry Report, 2019-2025GVR Report cover

![Sputtering Equipment Cathode Market Size, Share & Trends Report]()

Sputtering Equipment Cathode Market (2019 - 2025) Size, Share & Trends Analysis Report By Product (Linear, Circular), By Region (North America, Europe, Central & South America, Middle East & Africa, Asia Pacific), And Segment Forecasts

- Report ID: GVR-2-68038-736-0

- Number of Report Pages: 70

- Format: PDF

- Historical Range: 2014 - 2016

- Forecast Period: 2018 - 2025

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Sputtering Equipment Cathode Market Summary

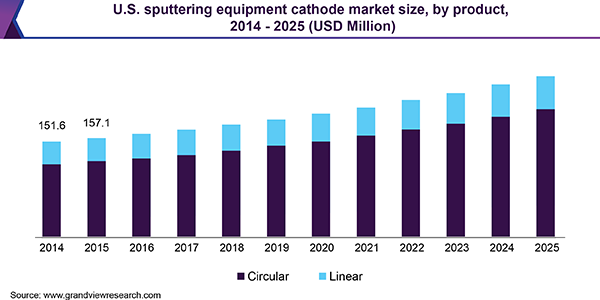

The global sputtering equipment cathode market size was estimated at USD 840.3 million in 2017 and is projected to reach USD 1.23 billion by 2025, growing at a CAGR of 4.9% from 2018 to 2025. Increasing the application of sputter coatings in the growing semiconductor industry is expected to be one of the primary factors driving the demand in the forthcoming years.

Key Market Trends & Insights

- The Asia Pacific leads the global market.

- China is expected to exhibit the highest automotive production during the forecast period.

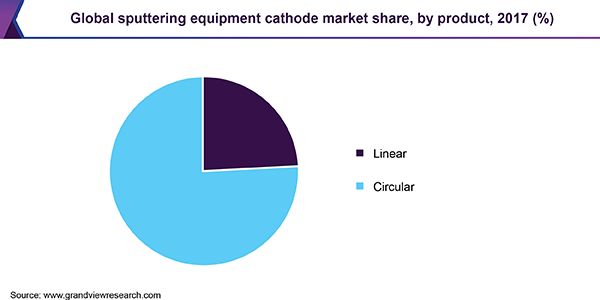

- Based on product, circular cathode segment accounted for USD 636.9 billion in 2017.

Market Size & Forecast

- 2017 Market Size: USD 840.3 Million

- 2025 Projected Market Size: USD 13.3 Billion

- CAGR (2018-2025): 10.9%

- Asia Pacific: Largest market in 2017

The advent of Artificial Intelligence (AI) across a wide range of industries, such as electronics and aerospace is likely to spur the demand for semiconductors, resulting in the growth of the market. Increasing the use of semiconductors to implement virtual reality in gaming is expected to further drive the growth. Strong commercial demand for fuel cells in the U.S., primarily driven by the public transport sector coupled with an enhanced production capacity of fuel cell manufacturers has led to a rise in fuel cell coating leading to market growth. Preference for magnetron sputtering for thin-film coating of fuel cells in automotive applications is likely to spur the demand for magnetron cathode in near future.

The introduction of confocal sputtering arrangement in magnetron sputtering technology is anticipated to boost the efficiency of the equipment. Moreover, it enables the incorporation of multiple magnetrons with different cathode materials. These factors are expected to boost the production output of the sputtering equipment, thereby driving the growth of the market. High requirement for industry-specific knowledge and technical know-how for the companies operating in the sputtering equipment cathode market results in a high entry cost which reduces the threat of new entrants. Also, the fragmented presence of localized manufacturers across the regions with high production capability lead high competitive environment in the industry.

Increased number of initiatives by key industry participants such as continuous investments in R&D to develop novel manufacturing processes is expected to enhance the volume throughput of the process. Moreover, new product development and technological advancements in the sputtering process are expected to further boost the growth soon.

The companies are implementing several innovative strategies such as development proprietary cathode technologies and materials to differentiate their products from the competitors and to gain competitive advantage. Also, the key players are investing in the development of products to resolve changes, such as uniformity, homogeneity, and purity.

The market does not exhibit the presence of any substitute as the cathode is an integral part of sputtering equipment. However, the presence of alternative technologies, such as thermal evaporation is expected to result in restrained market growth. As the industry does not exhibit any direct substitutes, the threat of substituting the product remains low.

Product Insights

Circular cathode accounts for the majority share of the industry as they can be used for coating substrates with intricate designs through the surface of the rotating target tube. This segmented accounted for USD 636.9 billion in 2017 and is expected to witness notable growth as the product provides enhanced arc rates, high power density, and has a low initial cost.

The segment is also expected to witness growth due to an increase in the use of advanced target materials such as silicon nitride, silicon dioxide, titanium dioxide, and niobium pentoxide. Also, the circular cathode is primarily used in coating temperature-sensitive materials, which in turn is expected to drive the market growth over the forecast period.

The linear cathode is primarily used in large scale sputtering systems and offers high deposition rates for physical vapor depositions coatings. It provides high production throughput on large substrates and also be seamlessly integrated into larger clusters of production tools to attain higher uniformity. This is expected to drive the product demand.

The linear cathode can withstand plasma at low gas pressure that requires special adjustments to achieve desired film properties. Also, the use of linear magnetron cathode results in higher deposition rates than the simple diode configuration cathode which results in a heightened demand.

Sputter deposition is also used in several applications, such as architectural and anti-reflective coatings, display web coatings, and automotive and decorative coating. Also, it is used for computer hard disk production and integrated circuit technology among other applications. Rising demand from these end-use applications is expected to spur the growth over the forecast period.

Variation in coating efficiency and fluctuations in price are expected to adversely affect the market. However, key companies are involved in the launch of new products, such as specialized DC power-based Physical Vapor Deposition (PVD) process used for semi-conductor and metal manufacturing processes, which in turn is expected to positively impact the market growth.

Regional Insights

The Asia Pacific leads the global market, owing to increasing semi-conductor production in China, India, South Korea, and Taiwan. Moreover, the high demand for PVD coatings from solar PV and medical equipment production industries is also anticipated to positively impact the growth shortly.

China is expected to exhibit the highest automotive production during the forecast period, which is projected to benefit the market as the industry utilizes numerous components coated using sputtering equipment. Also, growth in the production of hybrid/electric and green vehicles is expected to positively impact the regional market in the forthcoming years.

Europe is expected to witness a surge in demand over the forecast period owing to the immense demand for PVD coatings across various sectors, such as surgical tools and medical equipment. Besides, it is also replacing traditional coating methods, owing to the ban on chromium by European Commission, thereby driving the market growth.

Technological advancements in the robotics industry in Japan are predicted to bolster the demand for semi-conductor coatings. The demand for semiconductor chips is anticipated to be bolstered by the exponential demand from the robotics industry. This in turn is expected to drive the requirement for sputtering equipment, thereby driving the cathode market growth.

Key Companies & Market Share Insights

The market is competitive, owing to the presence of a large number of localized manufacturing companies. A large number of players in the industry are technology-driven and are targeting markets with long-term growth potential, where they can establish a sustainable competitive advantage.

Key players are also involved in the development of advanced manufacturing technologies, such as Vibration Cast Technology and confocal sputtering. Also, the companies invest significantly in the development of advanced technology solutions including customized alloy compositions.

Sputtering Equipment Cathode Market Report Scope

Report Attribute

Details

The market size value in 2019

USD 917.5 billion

The revenue forecast in 2025

USD 1223.7 billion

Growth Rate

CAGR of 4.9% from 2019 to 2025

The base year for estimation

2017

Historical data

2014 - 2016

Forecast period

2018 - 2025

Quantitative units

Revenue in USD billion and CAGR from 2019 to 2025

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, region

Regional scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country scope

U.S., Canada, Mexico, Germany, U.K., France, China, India, Japan, Brazil, South Africa

Key companies profiled

Kurt J. Lesker Company (KJLC), Veeco Instruments, Inc., Semicore Equipment, Inc., Impact Coatings AB.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Segments Covered in the ReportThis report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2014 to 2025. For this study, Grand View Research has segmented the global sputtering equipment cathode market report based on product and region:

-

Product Outlook (Revenue, USD Million, 2014 - 2025)

-

Linear

-

Circular

-

-

Regional Outlook (Revenue, USD Million, 2014 - 2025)

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

U.K.

-

France

-

-

Asia Pacific

-

China

-

Japan

-

India

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global sputtering equipment cathode market size was estimated at USD 917.5 million in 2019 and is expected to reach USD 961.0 million in 2020.

b. The global sputtering equipment cathode market is expected to grow at a compounded annual growth rate of 4.9% from 2019 to 2025 to reach USD 1,233.7 million in 2025.

b. Asia Pacific dominated the sputtering equipment cathode market with a share of 46.5% in 2019. This can be attributed to the increasing semi-conductor production in China, India, South Korea, and Taiwan.

b. Some key players operating in the sputtering equipment cathode market include Kurt J. Lesker Company (KJLC), Veeco Instruments, Inc., Semicore Equipment, Inc., Impact Coatings AB.

b. Key factors driving the sputtering equipment cathode market growth include increasing application of sputter coatings in the growing semi-conductor industry.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.