- Home

- »

- Advanced Interior Materials

- »

-

Tandem Piston Compressor Market Size, Share Report, 2030GVR Report cover

![Tandem Piston Compressor Market Size, Share & Trends Report]()

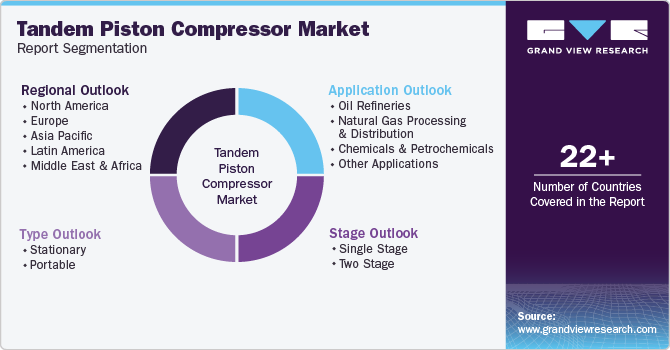

Tandem Piston Compressor Market (2025 - 2030) Size, Share & Trends Analysis Report By Type (Stationary, Portable), By Stage (Single Stage, Two Stage), By Application, By Region, And Segment Forecasts

- Report ID: GVR-4-68040-471-5

- Number of Report Pages: 152

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Tandem Piston Compressor Market Trends

The global tandem piston compressor market size was estimated at USD 6,025.5 million in 2024 and is anticipated to grow at a CAGR of 4.6% from 2025 to 2030. Increasing industrialization and the rising demand for compressed air across various sectors, such as Oil Refineries and construction, are significant contributors. As industries strive for energy efficiency, tandem piston compressors are favored for their ability to deliver high efficiency and reliability, making them ideal for heavy-duty applications.

Moreover, technological advancements are enhancing the performance and functionality of tandem piston compressors, enabling them to meet stringent regulatory standards and customer requirements. The shift towards automation and the increasing use of pneumatic tools in industrial settings further drive demand, as these compressors are essential for operating such equipment effectively.

Drivers, Opportunities & Restraints

The rising focus on preventive maintenance and operational reliability within various industries is driving market growth. Companies are increasingly investing in equipment that not only maximizes performance but also minimizes downtime. Tandem piston compressors, known for their durability and lower maintenance needs, are becoming a preferred choice for businesses aiming to enhance productivity.

Restraints include the high initial investment required for advanced tandem piston compressor systems, which can deter small and medium-sized enterprises from adopting this technology. In addition, the maintenance and operational costs associated with these compressors can be significant, especially for businesses with tight budgets.

The increasing demand for energy-efficient and environmentally friendly solutions presents a significant opportunity, as tandem piston compressors are designed to reduce energy consumption and emissions.

Type Insights

“The portable segment is expected to grow at a significant CAGR of 4.9% from 2024 to 2030 in terms of revenue.”

They benefit from the growing trend toward mobility in construction and maintenance applications. Their lightweight and compact design allows for easy transportation, making them ideal for on-site work where space and accessibility are limited. The rise in construction activities, infrastructure projects, and outdoor events drives the demand for portable compressors, as these units provide flexibility and immediate access to compressed air wherever needed.

The stationary segment dominated the market in 2023, accounting for 57.1% of the global revenue share. Stationary compressors are experiencing increased demand due to their robustness and suitability for fixed installations in industrial settings. As industries such as Oil Refineries and construction expand, stationary compressors are favored for their efficiency and ability to deliver consistent performance over long periods. Furthermore, technological advancements, including enhanced energy efficiency and reduced emissions, make stationary systems more attractive to companies seeking to optimize their operations while adhering to regulatory standards.

Application Insights

“The oil refineries segment is expected to grow at a significant CAGR of 4.7% from 2024 to 2030 in terms of revenue.”

In the oil refineries sector, the need for reliable and high-performance equipment drives the demand for tandem piston compressors. These compressors are essential for various processes, including gas compression and vapor recovery, where consistent operation and efficiency are critical. The ongoing investments in refinery expansions and modernization projects further fuel the demand for robust compressor solutions that can meet the stringent operational requirements of this industry.

The natural gas processing and distribution segment dominated in 2023, accounting for 30.7% of the market share. In natural gas processing and distribution, tandem piston compressors play a vital role in ensuring gas safe and efficient transportation. The increasing global focus on natural gas as a cleaner energy source and the expansion of pipeline infrastructure drive the demand for reliable compression systems. As new processing plants are developed and existing facilities upgraded, the need for high-performance compressors becomes increasingly important to handle the growing volumes of natural gas while maintaining safety and regulatory compliance.

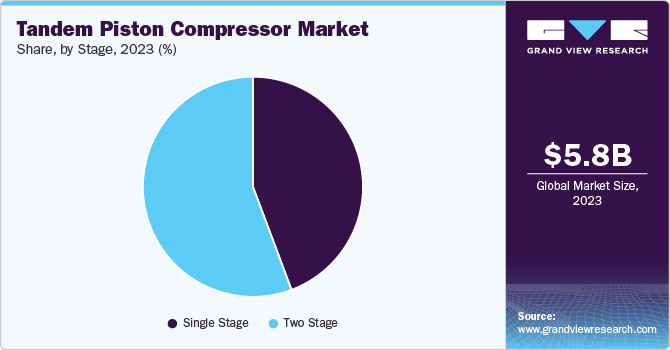

Stage Insights

"The two stage segment is expected to grow at a rapid CAGR of 4.8% from 2024 to 2030 in terms of revenue.”

Two stage compressors are favored in applications that require higher pressure and greater efficiency. Their design allows for better heat dissipation and improved performance, making them suitable for demanding industrial applications, including heavy-duty Oil Refineries. As industries increasingly focus on energy efficiency and productivity, the superior performance of two stage compressors positions them as a preferred option, particularly in sectors where high pressure is crucial.

The single stage segment accounted for 44.3% of the market share in 2023. Single stage compressors are popular for their simplicity and cost-effectiveness in applications requiring moderate pressure. They are particularly advantageous in smaller operations where the air demand is not overly high, making them an economical choice. The growing number of small to medium-sized enterprises across various industries bolstered the demand for single stage compressors, as they offer a straightforward solution without the complexity of multi-stage systems.

Regional Insights

“India to witness fastest market growth at 6.1% CAGR”

In Asia Pacific, rapid industrialization and urbanization are significant factors propelling market growth. Countries like China and India are expanding their oil refineries capabilities, increasing demand for reliable and efficient air compression solutions. Furthermore, government initiatives to boost infrastructure development and energy efficiency encourage investments in tandem piston compressors across various sectors.

The tandem piston compressor market in India is estimated to grow by 6.1% over the forecast period. In India, the market growth is driven by several key factors. The industrial sector remains a significant contributor, with Oil Refineries, oil and gas, and construction leading the demand for efficient air compression solutions. As companies prioritize energy efficiency to reduce operational costs and meet sustainability goals, there is a shift toward advanced compressor technologies that offer lower emissions and enhanced performance. Top of Form

North America Tandem Piston Compressor Market Trends

The tandem piston compressor market in North America is growing due to the robust industrial sector, particularly in Oil Refineries, oil and gas, and construction. The emphasis on energy efficiency and sustainability prompts industries to adopt advanced compressor technologies. Furthermore, ongoing investments in infrastructure and the trend towards automation in oil refinery processes further stimulate demand.

Europe Tandem Piston Compressor Market Trends

The tandem piston compressor market in Europe is largely driven by stringent environmental regulations and a strong focus on sustainability. Industries are increasingly seeking energy-efficient solutions to comply with these regulations. Moreover, the transition to renewable energy sources creates demand for compressors in various applications, such as natural gas processing and distribution. The presence of established manufacturers and ongoing technological innovations also contribute to market expansion in this region.

Key Tandem Piston Compressors Company Insights

Some key players operating in the market include Atlas Copco AB and WSP.

-

Atlas Copco AB is a manufacturer and provider of compressors, pumps, generators, power tools, and assembly systems through multiple brands such as ABAC, AGRE, AIRnet, ALUP, Balma, and American Pneumatic Tools (APT), among others. The company has a direct presence in over 70 countries and sales in more than 180.

-

Danfoss Group’s product portfolio includes compressors, district heating solutions, district cooling solutions, AC drives, valves, energy recovery devices, energy metering, pumps, sem-safe fire safety, steering, software, filter driers, sight glasses, and more. Danfoss serves customers across various sectors, including Natural Gas Processing and Distribution, energy, marine, building, industrial, mobility, and others, in regions such as Europe, North America, Asia Pacific, Latin America, Africa, and the Middle East.

Key Tandem Piston Compressors Companies:

The following are the leading companies in the tandem piston compressors market. These companies collectively hold the largest market share and dictate industry trends.

- Atlas Copco AB

- BOGE

- Shanghai Xinran Compressor Company (Asia-pacific Universal Machinery Company)

- Dorin S.p.A.

- BAC Compressors.

- NU AIR

- Danfoss AS

- FIMA s.r.l.

- Nardi Compressor SRL

- Castair

- REMEZA

- ELGi

- MGF Compressors Srl

- KOBE STEEL, LTD.

- Bristol Compressors

Recent Developments

-

In April 2022,ELGi Compressors Europe, part of ELGi Equipments Limited, revealed plans to launch the 'LD Series' of lubricated direct drive reciprocating air compressors in Europe. This innovative piston air compressor technology is designed to cater to various industries needing compact, high-performance compressors that operate quietly and require minimal maintenance. The ELGi LD Series offers capacities from 2.2 to 11 kW, representing a significant piston air compressor technology advancement.

-

Atlas Copco AB acquired Kingsdown Compressed Air Systems Limited, a distributor of compressed air and related equipment. Known for its robust sales and service, Kingsdown has a strong market presence. This acquisition aligns with Atlas Copco AB’s strategy to expand its geographical reach and improve our service to current and future customers.

Tandem Piston Compressor Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 6,259.6 million

Revenue forecast in 2030

USD 7,842.7 million

Growth rate

CAGR of 4.6% from 2025 to 2030

Actual data

2019 - 2024

Forecast period

2025 - 2030

Quantitative units

Revenue in USD million/billion, and CAGR from 2025 to 2030

Report coverage

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends

Segments covered

Type, state, application, region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country Scope

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; China; India; Japan; South Korea; Australia; Brazil;

Argentina; South Africa; Saudi Arabia; UAE

Key companies profiled

Atlas Copco AB; BOGE; Shanghai Xinran Compressor Company (Asia-pacific Universal Machinery Company); Dorin S.p.A.; BAC Compressors.; NU AIR; Danfoss AS; FIMA s.r.l.; Nardi Compressor SRL; Castair; REMEZA; ELGi; MGF Compressors Srl; KOBE STEEL, LTD.; Bristol Compressors

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Tandem Piston Compressor Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global tandem piston compressor market report based on the type, stage, application, and region:

-

Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Stationary

-

Portable

-

-

Stage Outlook (Revenue, USD Million, 2018 - 2030)

-

Single Stage

-

Two Stage

-

-

Application (Revenue, USD Million, 2018 - 2030)

-

Oil Refineries

-

Natural Gas Processing and Distribution

-

Chemicals and Petrochemicals

-

Other Applications

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global tandem piston compressor market size was estimated at USD 5.81 billion in 2023 and is expected to reach USD 7.84 billion in 2030.

b. The global tandem piston compressor market's revenue is expected to grow at a compound annual growth rate of 4.5% from 2024 to 2030, reaching USD 7.84 billion by 2030.

b. The Natural Gas Processing and Distribution segment dominated the market in 2023, accounting for 30.7% of the market share. The rising emphasis on natural gas as a cleaner energy alternative, alongside the expansion of pipeline networks, is significantly boosting the demand for dependable compression systems.

b. Some of the key players operating in the Tandem Piston Compressor Market are Atlas Copco AB, BOGE, Shanghai Xinran Compressor Company (Asia-pacific Universal Machinery Company), Dorin S.p.A., BAC Compressors., NU AIR, Danfoss AS, FIMA s.r.l., Nardi Compressor SRL, Castair, REMEZA, ELGi, MGF Compressors Srl, KOBE STEEL, LTD., and Bristol Compressors.

b. The global tandem piston compressors market is driven by increasing industrialization and the demand for energy-efficient, reliable compressed air solutions in sectors like manufacturing and construction. Technological advancements and the shift towards automation further boost demand, while environmental concerns promote the adoption of greener alternatives. Additionally, urbanization and diverse product offerings support market expansion, creating a favorable growth environment.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.