- Home

- »

- Advanced Interior Materials

- »

-

Wet Process Equipment Market Size, Industry Report, 2033GVR Report cover

![Wet Process Equipment Market Size, Share & Trends Report]()

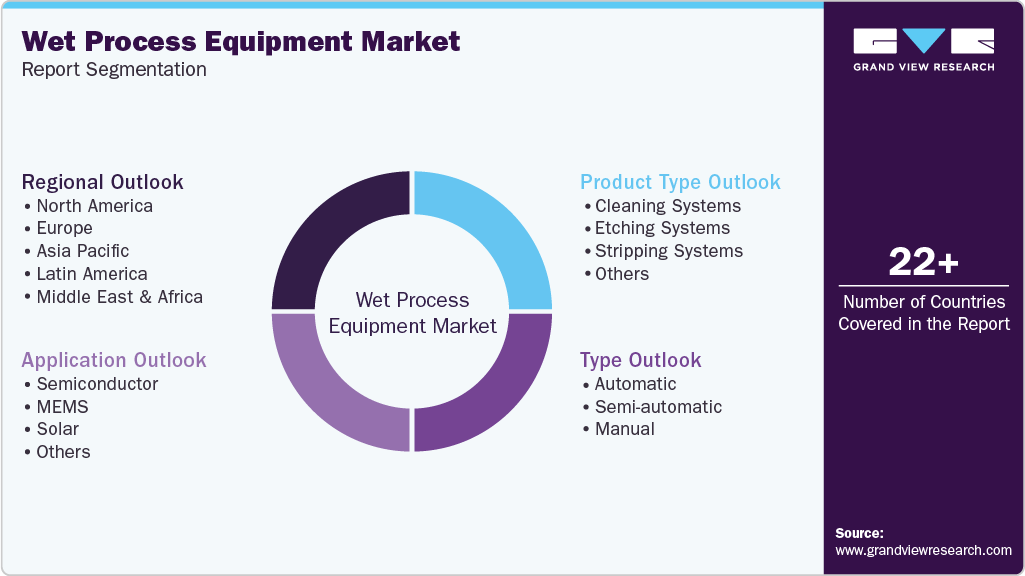

Wet Process Equipment Market (2025 - 2033) Size, Share & Trends Analysis Report By Product Type (Cleaning Systems, Etching Systems, Stripping Systems), By Type (Automatic, Semi-automatic, Manual), By Application (Semiconductor, MEMS, Solar), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-681-4

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2021 - 2023

- Forecast Period: 2025 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Wet Process Equipment Market Summary

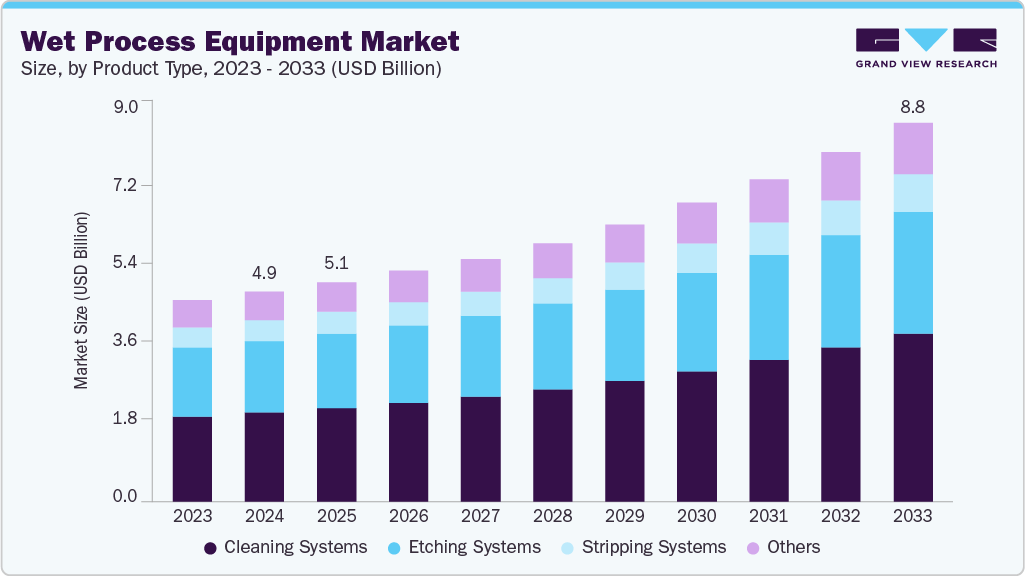

The global wet process equipment market size was estimated at USD 4,900.0 million in 2024 and is anticipated to reach USD 8,843.0 million by 2033, growing at a CAGR of 7.1% from 2025 to 2033. This growth is primarily driven by rising demand in semiconductor manufacturing, fueled by advanced technologies such as 5G, AI, and IoT.

Key Market Trends & Insights

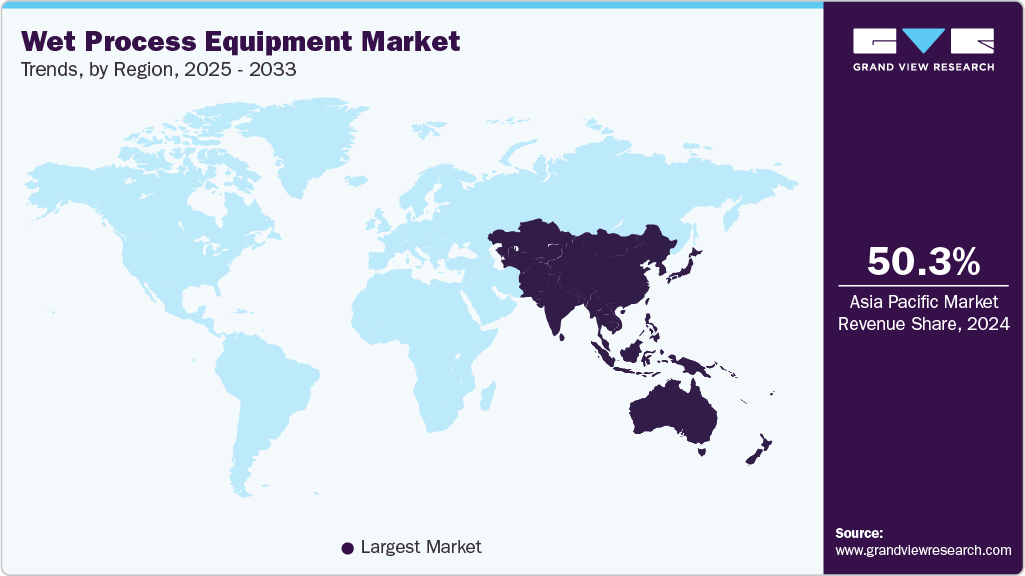

- Asia Pacific dominated the wet process equipment market with the largest revenue share of 50.3% in 2024.

- The wet process equipment market in the U.S. is expected to grow at a substantial CAGR of 8.3% from 2025 to 2033.

- By product type, cleaning systems segment is expected to grow at a considerable CAGR of 7.6% from 2025 to 2033 in terms of revenue.

- By type, the automatic segment is expected to grow at a considerable CAGR of 7.4% from 2025 to 2033 in terms of revenue.

- By application, semiconductor segment is expected to grow at a considerable CAGR of 7.5% from 2025 to 2033 in terms of revenue.

Market Size & Forecast

- 2024 Market Size: USD 4,900.0 Million

- 2033 Projected Market Size: USD 8,843.0 Million

- CAGR (2025-2033): 7.1%

- Asia Pacific: Largest market in 2024

Increased investment in chip fabrication facilities and the push for miniaturized, high-performance devices further support market expansion, especially in the Asia-Pacific and North America regions. In addition, growing consumer electronics usage, data center expansion, and national semiconductor policies are accelerating investments in fabrication facilities, further boosting market demand. The shift toward smaller process nodes and increased wafer sizes also necessitate advanced wet process solutions, positioning the market for strong and sustained growth.

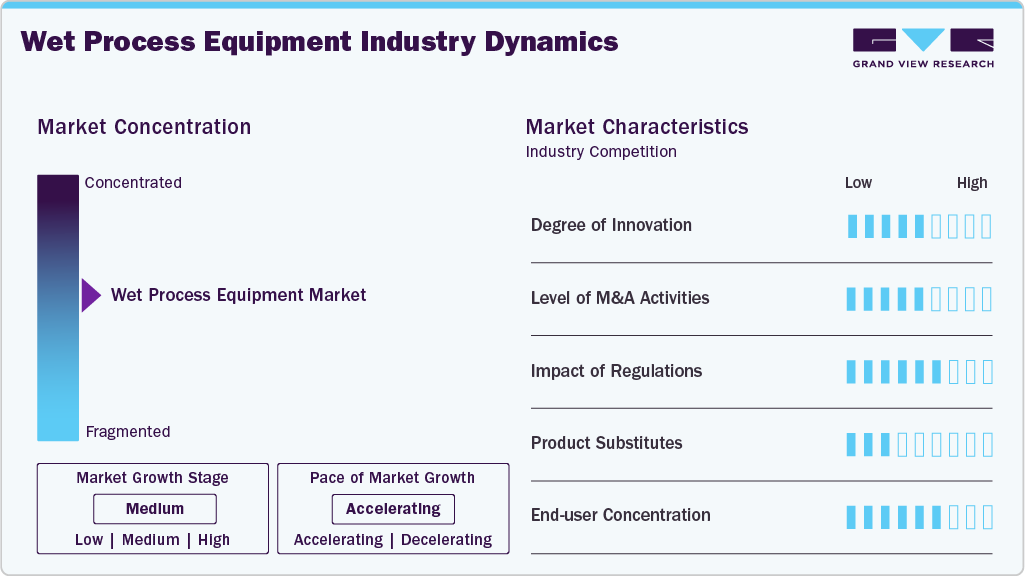

Market Concentration & Characteristics

The global wet process equipment market is moderately concentrated, with a few key players dominating a significant market share. Leading companies such as SCREEN Holdings, Tokyo Electron, Lam Research, and Applied Materials possess advanced technologies, strong R&D capabilities, and long-standing relationships with major semiconductor foundries and IDMs (Integrated Device Manufacturers).

The wet process equipment market exhibits a high degree of innovation, driven by rapid advancements in semiconductor technology. Continuous R&D focuses on improving precision, contamination control, and chemical usage efficiency. Innovations include advanced wafer cleaning, single-wafer processing, and eco-friendly solutions. As chip architecture evolves, equipment manufacturers must constantly adapt to meet the demanding requirements of next-generation semiconductor nodes.

Merger and acquisition activities in the wet process equipment market are strategic, aiming to enhance technological capabilities, expand product portfolios, and strengthen global presence. For instance, in November 2022 Lam Research acquired SEMSYSCO GmbH, a global provider of wet process equipment, to strengthen its capabilities in advanced semiconductor manufacturing. The acquisition enhances Lam’s portfolio with SEMSYSCO’s expertise in single-wafer wet processing, supporting next-generation chip production and reinforcing its position in the growing market for precision semiconductor fabrication technologies.

Regulations significantly influence the wet process equipment market by enforcing strict environmental and safety standards. Compliance with wastewater treatment, chemical handling, and emissions limits drives demand for advanced, efficient equipment. Governments promote sustainable manufacturing through policies, encouraging adoption of eco-friendly technologies. This regulatory pressure accelerates innovation and investments, shaping market growth and helping companies meet global compliance requirements effectively.

Drivers, Opportunities & Restraints

Rising demand for semiconductors due to technologies such as 5G, AI, and IoT is a key driver for the wet process equipment market. These technologies require advanced chips, increasing investment in fabrication facilities that need efficient wet process equipment, boosting market growth worldwide. This expansion boosts demand for highly efficient and precise wet process equipment, essential for cleaning, etching, and processing wafers during chip manufacturing, thereby driving the market globally.

Emerging economies, particularly in the Asia-Pacific, present significant growth opportunities for the wet process equipment market. Rapid expansion of the electronics manufacturing sector, combined with government initiatives promoting semiconductor production, is creating strong demand for advanced wet processing technologies.

High capital costs and complex maintenance requirements restrict market growth. Small manufacturers often find the expensive installation and upkeep of wet process systems prohibitive, limiting adoption despite technological benefits and regulatory demands.In addition, the technical complexity of operating and maintaining this equipment demands skilled labor, which may be limited in some regions.

Product Type Insights

The cleaning systems segment currently dominates the global wet process equipment market and accounted for 42.5% share in 2024. The growth is attributed to its essential role in removing contaminants from semiconductor wafers, ensuring high product quality. Advanced cleaning technologies improve efficiency and yield, making them vital in chip manufacturing. The growing demand for defect-free chips and stringent quality standards drives widespread adoption of cleaning systems across semiconductor manufacturing facilities globally.

Stripping systems are witnessing the fastest growth due to the increasing demand for efficient removal of photoresist and thin films in semiconductor fabrication. Advanced stripping technologies enhance precision, reduce defects, and improve manufacturing yields, driving widespread adoption across chipmakers focused on high-performance, miniaturized devices.

Type Insights

Automatic wet process equipment segment holds a 58.2% share in 2024 due to increasing demand for precision, reduced human error, and enhanced productivity in semiconductor and electronics manufacturing. Automation enables consistent, high-throughput processing, aligning with industry trends toward miniaturization and complex chip designs. This growth is further fueled by advancements in AI, robotics, and process control technologies.

Semi-automatic wet process equipment is experiencing significant growth due to its balance between manual control and automation. It offers greater flexibility and cost-efficiency compared to fully automatic systems. Manufacturers prefer it for easier integration, lower operational complexity, and improved process control, especially in mid-scale production environments and facilities gradually transitioning to full automation.

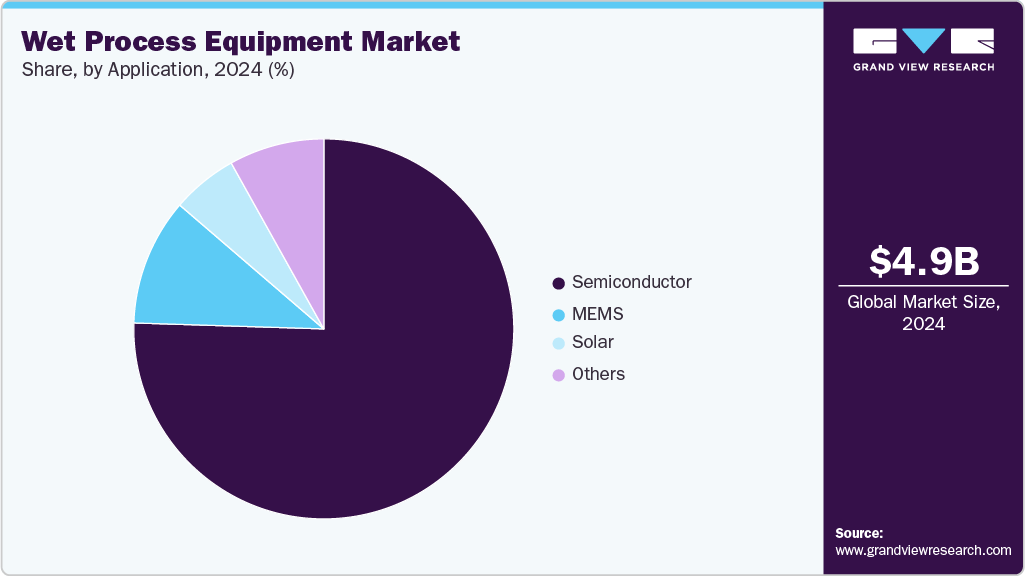

Application Insights

The semiconductor sector dominates the wet process equipment market and accounted for 75.5% share in 2024, due to rising demand for advanced chips in applications such as AI, 5G, and IoT. As chip designs become smaller and more complex, precise and contamination-free processing is critical. This fuels investment in wet process tools for cleaning, etching, and developing semiconductor wafers across global fabrication facilities.

MEMS segment is the fastest growing application in the market due to increasing use of micro-electromechanical systems in sensors, medical devices, and consumer electronics. MEMS production requires precise etching, cleaning, and surface treatment, making wet process equipment essential. As demand increases for compact, high-performance devices, manufacturers invest in specialized tools to improve MEMS fabrication efficiency and accuracy.

Regional Insights

North America wet process equipment market is growing at a significant CAGR of 7.9% over the forecast period, driven by the diversification of semiconductors and MEMS manufacturing facilities across the region. Investments in front-end manufacturing, automotive sensors, and health-tech drive demand for precise etching, cleaning, and chemical processing tools. With reshoring efforts and technological advances, U.S., Canada, and Mexico facilities adopt modern wet equipment to improve yield and support next-gen chip production.

U.S. Wet Process Equipment Market Trends

U.S. dominates the North American wet process equipment market, due to rising semiconductor fabrication and advanced packaging projects. Nationwide investments aim to increase domestic chip output, spurring demand for high-precision cleaning, etching, and wafer-surface treatment systems. This trend supports both new fab builds and upgrades in existing facilities, aligning with initiatives to strengthen technological self-reliance and supply chain resilience.

Wet process equipment market in Mexico is growing as electronics and automotive-related manufacturing expand nearshoring advantages. Local manufacturing facilities producing sensors and microelectronics increasingly integrate wet cleaning and etching systems to support precision requirements. Investments by global equipment suppliers and OEMs enhance regional production capacity.

Europe Wet Process Equipment Market Trends

Europe market is growing significantly driven by strong digital transformation and sustainability initiatives.Key industries like automotive sensors, renewable energy, and consumer electronics drive the need for precise wet processing. Countries such as Germany, UK France, Italy emphasize innovation and sustainability, shaping diverse equipment requirements in their manufacturing facilities.

Germany wet process equipment market dominates the European regionits strong automotive and semiconductor manufacturing sectors. The focus on Industry 4.0 and clean energy technologies encourages adoption of advanced chemical processing tools. Precision and automation are priorities, helping German manufacturers improve efficiency and product quality in highly competitive markets.

Wet process equipment market in UK is expected to grow steadily, driven by expanding semiconductor, photonics, and medical device manufacturing. Emphasis on advanced packaging and sensor technologies drives investment in specialized cleaning and etching systems. Innovation in sustainable manufacturing practices also influences the evolution of equipment used in UK production sites.

Asia Pacific Wet Process Equipment Market Trends

Asia Pacific is a dominant force in the market with 50.3% share, driven by advancements in semiconductor and MEMS manufacturing. Countries such as China, India, Taiwan, South Korea, and Japan are investing heavily in cutting-edge technologies, leading to increased demand for precision wet processing tools. This trend is further supported by government policies promoting technological self-sufficiency and innovation.

China wet process equipment market is witnessing strong growth fueled by substantial investments in semiconductor manufacturing. The government's initiatives, such as the "Made in China 2025" plan, aim to enhance domestic production capabilities and reduce reliance on foreign technologies. This strategic focus is accelerating the adoption of advanced wet process equipment across the country.

Wet process equipment market in India is growing rapidly bolstered by the government's support for semiconductor manufacturing. Initiatives such as the Production Linked Incentive (PLI) scheme are attracting investments in advanced manufacturing facilities. As a result, there is an increasing demand for specialized wet process equipment to meet the needs of the expanding semiconductor sector.

Middle East & Africa Wet Process Equipment Market Trends

The Middle East and Africa region is showing promising growth due to advancements in semiconductor and clean energy sectors. Countries like Israel and the UAE are investing in technology infrastructure, enhancing their manufacturing capabilities. This trend is fostering the adoption of precision wet processing tools, supporting the region's industrial diversification efforts.

Saudi Arabia wet process equipment market is witnessing significant growth propelled by its Vision 2030 initiative aimed at economic diversification. The establishment of industrial hubs such as Jubail and Sudair Industrial Cities is fostering the development of advanced manufacturing facilities. These developments are increasing the demand for specialized wet process equipment to support various sectors, including petrochemicals, automotive, and electronics.

Latin America Wet Process Equipment Market Trends

Latin America is a growing region in the wet process equipment market, driven by increasing investments in semiconductor manufacturing and electronics assembly. Countries like Brazil are enhancing their technological capabilities, fostering demand for advanced wet processing tools. Government incentives and international partnerships are further supporting the development of local manufacturing facilities, contributing to the region's industrial advancement.

Brazil wet process equipment market is growing steadily due to rising investments in infrastructure, energy, and industrial sectors. Investments in manufacturing facilities and research centers are promoting the adoption of advanced wet processing technologies.Additionally, increasing demand for electronics, automotive components, and renewable energy technologies is driving modernization.

Key Wet Process Equipment Company Insights

Some of the key players operating in the market include Felcon Ltd., Modutek Corporation, Plastic Design, Inc.

-

Felcon Ltd., established in 1971 and based in Newhaven, UK, specializes in manufacturing specialist equipment for cleanrooms, laboratories, and hospitals. The company offers a range of products, including wet process systems, laminar flow units, and isolators, designed to meet stringent contamination control standards. With a focus on innovation and customer satisfaction, Felcon Ltd. serves various industries, providing tailored solutions to ensure optimal performance in controlled environments.

-

Modutek Corporation is a provider of wet process equipment for the semiconductor industry. The company designs and manufactures a comprehensive range of products, including wet benches, chemical delivery systems, and precision parts cleaning systems. Modutek emphasizes customization, offering tailored solutions to meet specific customer requirements. With a focus on precision, reliability, and innovation, Modutek supports semiconductor manufacturers in achieving high-quality results and efficient production processes.

Key Wet Process Equipment Companies:

The following are the leading companies in the wet process equipment market. These companies collectively hold the largest market share and dictate industry trends.

- Felcon Ltd.

- Modutek Corporation

- Plastic Design, Inc.

- Tokyo Electron Limited

- Lam Research Corporation

- Applied Materials, Inc.

- SCREEN Holdings Co., Ltd.

- Semes Co., Ltd.

- Shibaura Mechatronics Corporation

- Rena Technologies GmbH

- Veeco Instruments Inc.

- Akrion Systems LLC

- MicroTech Systems, Inc.

- Wafer Process Systems, Inc.

- Solid State Equipment LLC

Recent Developments

-

In April 2025, Tokyo Electron Miyagi completed its new development building to support growing semiconductor demand. As digital transformation accelerates, advanced patterning technologies for complex, smaller chips are vital. This expansion positions Tokyo Electron Miyagi to meet rising market needs, especially for its cutting-edge etch systems critical to semiconductor innovation.

-

In September 2024, Tokyo Electron Ltd. Announced expansion in India by hiring and training chip engineers by 2026. This move aligns with the Indian government’s push, to boost domestic semiconductor manufacturing, supporting India’s goal to become a significant player in the global chip industry.

Wet Process Equipment Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 5,120.0 million

Revenue forecast in 2033

USD 8,843.0 million

Growth rate

CAGR of 7.1% from 2025 to 2033

Base year for estimation

2024

Historical data

2021 - 2023

Forecast period

2025 - 2033

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2033

Report coverage

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends

Segments covered

Product type, type, application, region

Regional scope

North America; Europe; Asia Pacific; Latin America; and Middle East & Africa

Country Scope

U.S.; Canada; Mexico; Germany; France; UK; Germany; Italy; Spain; China; Japan; India; South Korea; Australia; Taiwan; Brazil; Argentina; South Africa; Saudi Arabia; UAE; Turkey

Key companies profiled

Felcon Ltd.; Modutek Corporation; Plastic Design, Inc.; Tokyo Electron Limited; Lam Research Corporation; Applied Materials, Inc.; SCREEN Holdings Co., Ltd.; Semes Co., Ltd.; Shibaura Mechatronics Corporation; Rena Technologies GmbH; Veeco Instruments Inc.; Akrion Systems LLC; MicroTech Systems, Inc.; Wafer Process Systems, Inc.; Solid State Equipment LLC.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Wet Process Equipment Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis on the industry trends in each of the sub-segments from 2025 to 2033. For this study, Grand View Research has segmented the wet process equipment market based on product type, type, application, and region:

-

Product Type Outlook (Revenue, USD Million, 2021 - 2033)

-

Cleaning Systems

-

Etching Systems

-

Stripping Systems

-

Others

-

-

Type Outlook (Revenue, USD Million, 2021 - 2033)

-

Automatic

-

Semi-automatic

-

Manual

-

-

Application Outlook (Revenue, USD Million, 2021 - 2033)

-

Semiconductor

-

MEMS

-

Solar

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2021 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

Australia

-

South Korea

-

Taiwan

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Saudi Arabia

-

UAE

-

South Korea

-

Turkey

-

-

Frequently Asked Questions About This Report

b. Some of the key players operating in the wet process equipment market include Felcon Ltd., Modutek Corporation, Plastic Design, Inc., Tokyo Electron Limited, Lam Research Corporation, Applied Materials, Inc., SCREEN Holdings Co., Ltd., Semes Co., Ltd., Shibaura Mechatronics Corporation, Rena Technologies GmbH, Veeco Instruments Inc., Akrion Systems LLC, MicroTech Systems, Inc., Wafer Process Systems, Inc., Solid State Equipment LLC. and among others.

b. The global wet process equipment market size was estimated at USD 4,900.0 million in 2024 and is expected to reach USD 5,120.0 million in 2025.

b. The wet process equipment market, in terms of revenue, is expected to grow at a compound annual growth rate of 7.1% from 2025 to 2033 to reach USD 8,843.0 million by 2033.

b. Automatic wet process equipment segment holds a 58.2% share due to increasing demand for precision, reduced human error, and enhanced productivity in semiconductor and electronics manufacturing. Automation enables consistent, high-throughput processing, aligning with industry trends toward miniaturization and complex chip designs.

b. Key factors driving the wet process equipment market include rising demand for advanced semiconductors, miniaturization of electronic devices, and growth in MEMS. Technological advancements, need for precise wafer cleaning and etching, and increased investments in semiconductor manufacturing also contribute to the market’s significant expansion across regions.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.