- Home

- »

- Advanced Interior Materials

- »

-

Food Processing Seals Market Size, Industry Report, 2020-2027GVR Report cover

![Food Processing Seals Market Size, Share & Trends Report]()

Food Processing Seals Market Size, Share & Trends Analysis Report By Material (Face Materials, Metal, Elastomers), By Application (Bakery & Confectionery, Beverages), By Region, And Segment Forecasts, 2020 - 2027

- Report ID: GVR-4-68038-746-9

- Number of Pages: 120

- Format: Electronic (PDF)

- Historical Range: 2016 - 2018

- Industry: Advanced Materials

Report Overview

The global food processing seals market size was valued at USD 2.8 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 2.5% from 2020 to 2027. Increasing use of the product to avoid food contamination and leakage is anticipated to promote the expansion of the industry. In addition, rising demand for packaged foods and beverages is likely to benefit market growth.

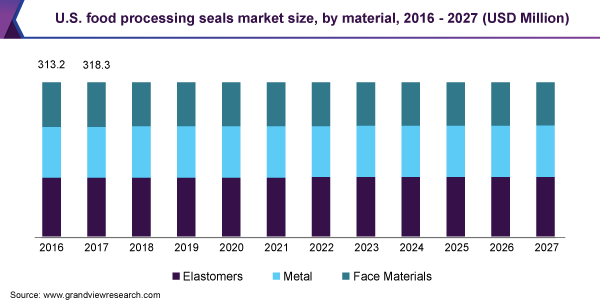

Improved standards of living coupled with rising spending capacity among individuals across major economies, such as the U.S., China, India, the U.K., and Germany, are projected to benefit the demand for processed foods and beverages, thereby supporting the market growth. The U.S. market was valued at USD 329.4 million in 2019 and is estimated to grow at a CAGR of 2% from 2020 to 2027.

Rising demand for bakery products and packaged alcoholic and non-alcoholic drinks is anticipated to propel the market growth over the forecast period. Moreover, stringent regulations pertaining to the use of the product and seal materials are anticipated to benefit the market growth over the forecast period. In addition, rising demand for dairy and meat products is anticipated to stimulate market growth. However, volatile raw material prices are projected to have a negative impact on the overall market growth.

In addition, growing demand for healthy, organic and fresh food products is expected to limit the demand for food processing seals, which, in turn, will limit the industry growth over the forecast period. Rapid urbanization coupled with changing patterns of food consumption across the globe is anticipated to fuel market growth. Furthermore, rising demand for baked products is anticipated to propel the market growth.

Material Insights

The elastomers materials segment accounted for the largest market share of more than 74% in 2019 and is projected to expand further at the fastest CAGR of 2.8% from 2020 to 2027. Factors, such as chemical compatibility coupled with high rate of replacement as compared to other materials including metals, face materials, and others is anticipated to promote segmental growth. Moreover, elastomers are highly resistant to water, oils, greases, acids, alcohols, and others, which boosts their demand in the manufacturing of seals. Metal seals segment is projected to account for the second-largest market share by 2027.

This growth is attributed to the increasing demand of metal seals in applications including bakery & confectionery and others. In addition, the material offers flexibility of design and can be exposed to extreme temperature and chemical reactions. This is anticipated to propel the segment growth over the forecast period. Face materials, such as carbon, ceramic, silicon carbide, and tungsten carbide, are increasingly being used in the manufacturing of seals. The superior strength of these materials to resist the environmental abrasion is projected to promote their demand across the industry.

Application Insights

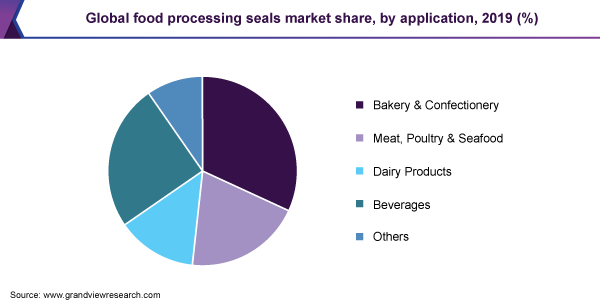

Bakery & confectionery application segment accounted for the maximum market share of over 30% in 2019 and is projected to retain its leading position throughout the forecast years. Rising demand for bakery products is projected to fuel the segment growth. The beverages application segment is anticipated to register the fastest CAGR from 2020 to 2027 on account of the growing demand for alcoholic and non-alcoholic packaged drinks.

Rising demand for meat products, due to rising consumer disposable income levels coupled with improved standard of living, is anticipated to boost the meat, poultry & seafood segment growth in the coming years. Dairy products segment is projected to witness a steady growth over the forecast period on account of the rising demand for cheese, butter, frozen desserts, ice creams, yogurt, dips, and other dairy products. Rapid urbanization coupled with stringent regulations related to food safety is projected to promote the dairy products demand, thereby driving the segment growth.

Regional Insights

Europe led the global food processing seals market in 2019 and held for over 37% of the overall market share. The region is projected to retain its dominant position throughout the forecast period on account of the rising food production and processing in the region. In addition, high demand for fast foods in Germany, U.K., France, and other European countries is estimated to drive the regional market. Asia Pacific is projected to register the fastest CAGR from 2020 to 2027 owing to rapid urbanization coupled with the growing demand for packaged foods in the developing economies, such as China, India, Indonesia, and Japan.

In addition, rising per capita spending of the end-users in the region is anticipated to further promote the industry growth. China accounted for a major share in the Asia Pacific regional market on account of the rapidly increasing population coupled with rising demand for processed food products. The North America region is projected to have a significant growth due to demand for bakery, meat and poultry products and alcoholic and non-alcoholic drinks.

Key Companies & Market Share Insights

The key companies are focusing on expanding their production capacities by establishing manufacturing facilities in economies, such as Brazil and Indonesia. In addition, companies are investing in R&D to introduce new products to gain a competitive advantage. Other strategies undertaken by the market participants include mergers, acquisition, and partnerships. Some of the prominent players in the food processing seals market include:

-

AESSEAL Plc

-

Smiths Group Plc

-

A.W. Chesterton Company

-

SKF

-

Trelleborg AB

-

Flowserve Corp.

-

James Walker

-

Meccanotecnica Umbra S.p.A.

-

EnPro Industries, Inc.

Food Processing Seals Market Report Scope

Report Attribute

Details

Market size value in 2020

2.9 Billion

Revenue forecast in 2027

3.5 Billion

Growth Rate

CAGR of 2.5% from 2020 to 2027

Base year for estimation

2019

Historical data

2016 - 2018

Forecast period

2020 - 2027

Quantitative units

Revenue in USD million and CAGR from 2020 to 2027

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Material, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; MEA

Country scope

U.S.; Canada; Mexico; Germany; U.K.; Spain; Italy; China; India; Japan; Brazil

Key companies profiled

AESSEAL Plc; Smiths Group Plc; A.W. Chesterton Company; SKF; Trelleborg AB; James Walker; Flowserve Corp.; Meccanotecnica Umbra S.p.A.; EnPro Industries, Inc.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Segments Covered in the ReportThis report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2016 to 2027. For the purpose of this study, Grand View Research has segmented the global food processing seals market report on the basis of material, application, and region:

-

Material Outlook (Revenue, USD Million, 2016 - 2027)

-

Metal

-

Face Materials

-

Elastomers

-

-

Application Outlook (Revenue, USD Million, 2016 - 2027)

-

Bakery & Confectionery

-

Meat, Poultry & Seafood

-

Dairy Products

-

Beverages

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2016 - 2027)

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

The U.K.

-

Spain

-

Italy

-

-

Asia Pacific

-

China

-

India

-

Japan

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global food processing seals market size was estimated at USD 2.8 billion in 2019 and is expected to reach USD 2.9 billion in 2020.

b. The global food processing seals market is expected to grow at a compound annual growth rate a CAGR of 2.5% from 2020 to 2027 to reach USD 3.5 billion by 2027.

b. Europe dominated the food processing seals market with a share of 37.6% in 2019. This is attributable to the rising demand for processed food coupled with the stringent regulations related to the use of seals in various food & beverage applications.

b. Some key players operating in the food processing seals market include Freudenberg Group), AESSEAL Plc, Smiths Group Plc, Flowserve Corporation, A.W. Chesterton Company, SKF, Parker Hannifin, Trelleborg AB, IDEX Corporation, EnPro Industries, Inc., James Walker, and Meccanotecnica Umbra S.p.A.

b. Key factors that are driving the market growth include increasing demand for processed food, convenience food coupled with the stringent regulations related to food safety across the globe.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."