- Home

- »

- Advanced Interior Materials

- »

-

Hybrid Additive Manufacturing Market Size Report, 2030GVR Report cover

![Hybrid Additive Manufacturing Market Size, Share & Trends Report]()

Hybrid Additive Manufacturing Market (2023 - 2030) Size, Share & Trends Analysis Report By Material (Titanium, Aluminum, Steel, Nickel, Others), By End-use, By Region, And Segment Forecasts

- Report ID: GVR-4-68038-598-4

- Number of Report Pages: 92

- Format: PDF

- Historical Range: 2018 - 2021

- Forecast Period: 2023 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Market Size & Trends

The global hybrid additive manufacturing market size was valued at USD 191.3 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 22.2% from 2023 to 2030. The market growth is anticipated to be driven by the increasing adoption of 3D printing and hybrid additive manufacturing in the aerospace, medical, and automotive sectors. In addition, the growing demand for customized products also presents significant growth opportunities for the market.

The COVID-19 pandemic had a negative impact on the global market for hybrid additive manufacturing. The pandemic disrupted global supply chains, leading to raw materials, components, and equipment shortages. This has affected the hybrid additive manufacturing sector, as many manufacturers rely on imported materials and equipment. The pandemic led to a reduction in demand for many manufactured products, including those produced using hybrid additive manufacturing. This had forced some manufacturers to scale back production and delay investment in new technology.

Despite the challenges, the pandemic had also accelerated the adoption of additive manufacturing in some industries, as it offers the ability to quickly produce parts and components locally, reducing reliance on global supply chains. For example, many companies used additive manufacturing during the pandemic to produce critical medical supplies, such as ventilator parts and face shields. For instance, HP India collaborated with several partners to design and produce critical components for ventilators, such as control valves and connectors, using 3D printing technology. The project was initiated in response to the shortage of ventilator parts during the COVID-19 pandemic. The team worked round the clock for 24 days to produce 120,000 3D printed parts, which were then assembled into ventilators by AgVa Healthcare, a leading medical equipment manufacturer. The ventilators were approved by the Indian government and were deployed in various hospitals to treat COVID-19 patients.

The government of the U.S. has recognized the potential of different new manufacturing techniques, including additive manufacturing, and invested in research & development in this area. For instance, in September 2021, The Future Manufacturing program by National Science Foundation (NSF) granted USD 31.5 million to fund 22 new research and seed projects. These grants support research and education at 40 different universities and two companies, spread across 18 states. Auburn University has been leading the Federated Deep Learning for Future Ubiquitous Distributed Additive Manufacturing project, along with George Mason University. The project aims to explore the application of federated deep learning in the context of ubiquitously distributed additive manufacturing.

Material Insights

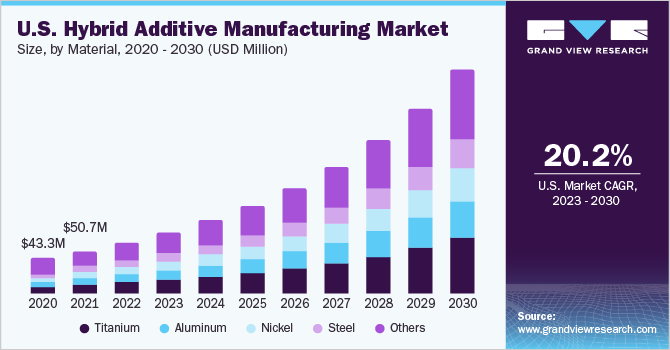

Based on material, the market is segmented into titanium, aluminum, steel, nickel, and others. The titanium segment held a revenue share of 23.1% in 2022 and is expected to register a CAGR of 23.4% over the forecast period. Titanium emerged as a highly promising material for utilization in 3D printing due to its high strength-to-weight ratio, outstanding mechanical strength, and superior corrosion resistance compared to stainless steel. As a result, it has become a popular choice for additive manufacturing in diverse fields such as aerospace, medicine, race car manufacturing, and electronics. Titanium is utilized extensively in the aerospace industry for an array of applications ranging from fighter jets and helicopters to rocket engines, pressure vessels, and structural components. The adoption of sustainable "green" titanium for additive manufacturing has the potential to revolutionize the industry. In December 2021, Boeing, a global leader in the aerospace industry, entered a partnership with Titomic, a Melbourne-based additive manufacturing innovator, to explore the potential application of sustainable "green" titanium in the production of space components.

The nickel segment is projected to grow at the second-highest CAGR of 22.9% over the forecast period. Nickel-based alloys are increasingly being used in hybrid additive manufacturing to produce complex parts with greater accuracy and efficiency. Nickel-based alloys, such as Inconel and Hastelloy, are highly resistant to heat, corrosion, and wear, making them ideal for use in applications that require high-performance parts in extreme environments such as aerospace, defense, and energy industries. In September 2022, Inconel 625, a highly corrosion-resistant nickel-based alloy, has been qualified on all of Desktop Metal's 3D printing systems including the Shop System. The Shop System is a highly versatile metal-binder jetting 3D printer designed for rapid prototyping and low-volume production, capable of producing complex geometries with high accuracy and consistency.

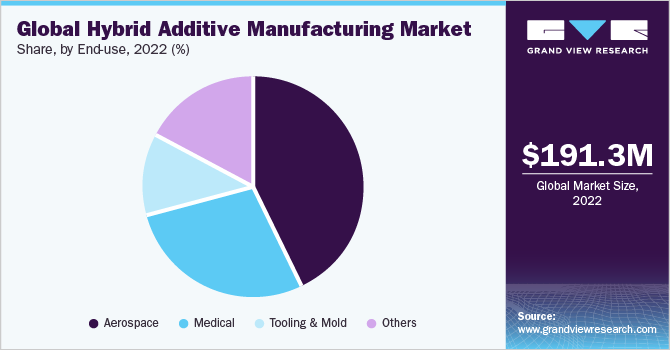

End-use Insights

Based on end-use, the market is segmented into aerospace, tooling & mold, medical, and others. The aerospace segment accounted for the largest revenue share of 43.1% in 2022 and is projected to grow at a CAGR of 22.4% over the forecast period. Additive manufacturing technologies enable the production of complex aerospace component designs using less material, resulting in improved buy-to-fly and strength-to-weight ratios, as well as lighter and more fuel-efficient designs that meet mechanical requirements.

In December 2022, Fortius Metals, Inc., a metal additive manufacturing (AM) startup, secured a seed funding round of USD 2 million from AM Ventures to expand its 3D printing technology in the aerospace industry.

The medical segment is likely to grow at the fastest CAGR of 24.1% over the forecast period. Hybrid additive manufacturing is being increasingly adopted in the medical industry for producing customized implants including customized dental implants. Titanium is a popular material used for these implants due to its excellent biocompatibility, strength, and corrosion resistance. Hybrid additive manufacturing is also used to create custom prosthetic limbs, wherein a titanium lattice structure is first formed, which is then coated with aluminum.

Regional Insights

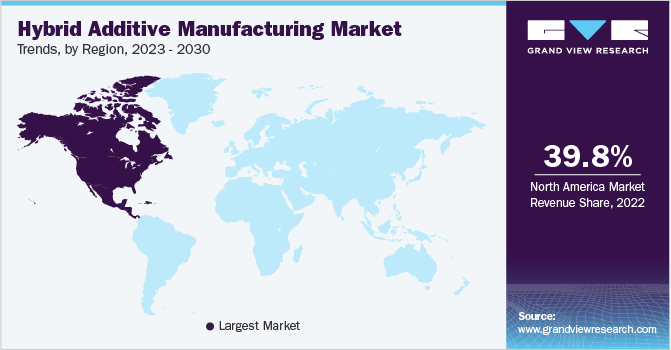

North America dominated the market with a share of 39.8% in 2022 and is anticipated to expand at a CAGR of over 21.4% over the forecast period. North America is one of the key regional markets for hybrid additive manufacturing. The demand for hybrid additive manufacturing and various raw materials, such as titanium, aluminum, nickel, and cobalt chrome, among others, is expected to increase owing to the increasing adoption of 3D printing in various end-use industries in the region. As per the Mexican, Aerospace Industry Federation estimates, from 2004 to mid-2022, the aerospace industry in Mexico experienced significant growth, expanding from 100 manufacturing firms and organizations to 368.

Asia-Pacific is expected to grow at the highest CAGR of 24.2% during the forecast period. In Asia Pacific, the governments of China, Japan, Singapore, and South Korea are investing in the research & development of advanced manufacturing technologies to promote innovation and competitiveness in their respective industries. For instance, Singapore's government developed an Advanced Manufacturing and Engineering Masterplan that focuses on additive manufacturing including hybrid additive manufacturing. The plan includes initiatives to support research & development in this area, as well as the development of a skilled workforce.

Key Companies & Market Share Insights

The competitive landscape of the market for hybrid additive manufacturing is consolidated, having a few global as well as local hybrid additive manufacturing solutions & raw material providers. The key participants are adopting strategic initiatives such as collaboration & partnerships, expansion, and product launches.

In March 2023, Materialise, a global leader in 3D printing software and services, made two major announcements at the AMUG (Additive Manufacturing Users Group) Conference. The first announcement was the launch of its process control software for metal 3D printing. This software is designed to provide users with increased control and transparency over the 3D printing process, helping to ensure the production of high-quality metal parts. The second announcement was the launch of its Build Processor Software Development (BP SDK). This software is designed to allow users to customize their 3D printing workflows and integrate Materialise's software with other software platforms. Some prominent players in the global hybrid additive manufacturing market are:

-

Materialise

-

Höganäs AB

-

GENERAL ELECTRIC

-

Renishaw plc.

-

3D Systems, Inc.

-

GKN Powder Metallurgy

-

Sandvik AB

-

ExOne

-

voxeljet AG

-

CRS Holdings, LLC.

Hybrid Additive Manufacturing Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 232.7 million

Revenue forecast in 2030

USD 948.6 million

Growth rate

CAGR of 22.2% from 2023 to 2030

Base year for estimation

2022

Historical data

2018 - 2021

Forecast period

2023 - 2030

Report updated

June 2023

Quantitative units

Revenue in USD million, and CAGR from 2023 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Material, end-use, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; MEA

Country scope

U.S.; Germany; Spain; China; Japan

Key companies profiled

Materialise; Höganäs AB; GENERAL ELECTRIC; Renishaw plc.; 3D Systems, Inc.; GKN Powder Metallurgy; Sandvik AB; ExOne, voxeljet AG; CRS Holdings, LLC.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional, and segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Hybrid Additive Manufacturing Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global hybrid additive manufacturing market report based on material, end-use, and region:

-

Material Outlook (Revenue, USD Million, 2018 - 2030)

-

Titanium

-

Aluminum

-

Steel

-

Nickel

-

Others

-

-

End-use Outlook (Revenue, USD Million, 2018 - 2030)

-

Aerospace

-

Tooling And Mold

-

Medical

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

-

Europe

-

Germany

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

-

Central & South America

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global hybrid additive manufacturing market size was estimated at USD 191.3 million in 2022 and is expected to reach USD 232.7 million in 2023.

b. The global hybrid additive manufacturing market is expected to grow at a compound annual growth rate of 22.2% from 2023 to 2030 to reach USD 948.5 million by 2030.

b. Based on region, North America dominated the hybrid additive manufacturing market with a share of nearly 40.0% in 2022. This can be attributable to the increasing adoption of hybrid additive manufacturing in various end-use industries in the region.

b. Some key players operating in the hybrid additive manufacturing market include Materialise, Höganäs AB, GENERAL ELECTRIC, Renishaw plc., 3D Systems, Inc., GKN Powder Metallurgy, Sandvik AB, ExOne, voxeljet AG, and CRS Holdings, among others.

b. The growing demand for customized products across various industries is driving market growth. Moreover, the increasing demand for additive manufacturing from the aerospace and medical industries offers significant growth opportunities.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.