- Home

- »

- Plastics, Polymers & Resins

- »

-

Liquid Silicone Rubber Market Size Report, 2030GVR Report cover

![Liquid Silicone Rubber Market Size, Share & Trends Report]()

Liquid Silicone Rubber Market (2024 - 2030) Size, Share & Trends Analysis Report, By Grade (Medical, Food, Industrial), By Application (Medical, Automotive, Consumer Goods), By Region, And Segment Forecasts

- Report ID: GVR-1-68038-436-9

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Liquid Silicone Rubber Market Summary

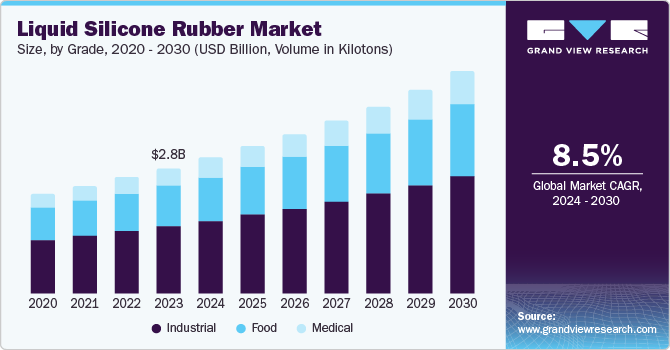

The global liquid silicone rubber market size was valued at USD 2.81 billion in 2023 and is projected to reach USD 4.97 billion by 2030, growing at a CAGR of 8.5% from 2024 to 2030. Increasing demand from the medical and automotive industries has emerged as the key driver for the overall market during the forecast period.

Key Market Trends & Insights

- North America liquid silicone rubber market dominated the global market in terms of revenue share of 37.4% in 2023.

- The U.S. liquid silicone rubber market had a substantial market share of 87.4% in North America.

- Asia Pacific liquid silicone rubber market held a market share of 26.6% in 2023.

- Based on grade, the industrial segment dominated the market in 2023 with a share of 53.2%.

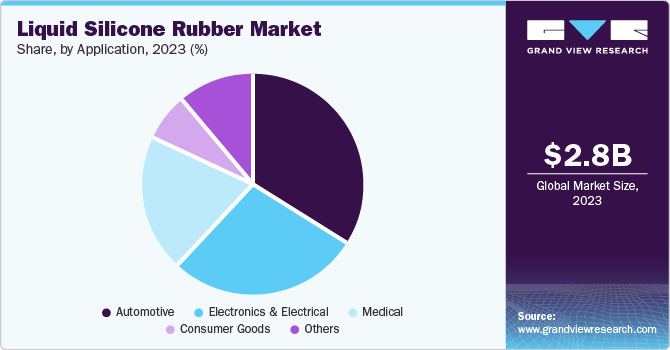

- In terms of application, the automotive segment dominated the market in 2023, with a share of 34.1%.

Market Size & Forecast

- 2023 Market Size: USD 2.81 Billion

- 2030 Projected Market Size: USD 4.97 Billion

- CAGR (2024-2030): 8.5%

- North America: Largest market in 2023

Industries such as automotive and medical are witnessing huge demand owing to their cost-effectiveness, durability, and ability to meet all safety requirements. Liquid silicone rubber has become one of the prime manufacturing materials these days. It is used in applications such as food molds, anti-snoring devices, LEDs, and medical devices. It is among the several innovative materials utilized in the automotive industry to manufacture gaskets. Liquid silicone rubber is resistant to hot and cold temperatures, which makes it suitable for automotive applications.

There is an increase in the demand for liquid silicone rubber in the production of medical devices due to its temperature resistance and disinfection properties. The material is used in the production of products such as dialysis channels, needle plugs, and breathing devices. The spread of contamination and hospital-acquired infections (HAIs) can be minimized using devices made from liquid silicone rubber due to its disinfectant properties. Furthermore, there is an increased demand for LSR in sectors such as construction, aerospace, electronics, and food and beverages. It is utilized to produce sealants, adhesives, potting materials, lubricants, coatings, and more.

Liquid silicone rubber (LSR) has unique properties such as electrical resistance, chemical inertness, and the ability to withstand extreme temperatures. These properties have enabled its broad adoption across medical, electrical electronics, automotive, and several other industries. The rising geriatric population is fueling the medical industry's demand for medical implants and devices.

Grade Insights

The industrial segment dominated the market in 2023 with a share of 53.2% attributed to the increased demand for products made from liquid silicone rubber, which has properties such as temperature, chemical, and electrical resistance. The material's malleability aids in the manufacturing of various molds. Furthermore, growth in the industrial sector and increased demand for products made from liquid silicone rubber have resulted in the market growth of this segment.

The medical segment is expected to grow at a CAGR of 9.2% during the forecast period. Devices manufactured from medical-grade LSR improve life expectancy as they reduce pain and are useful in making artificial joints and pacemakers. Rings, gaskets, stoppers, closures, catheters, cushioning pads, and liquid feeding bottles are a few of the products manufactured with medical-grade LSR. Products made from LSR aid in avoiding contamination and HAIs. Hence, these factors are responsible for the market growth of this segment.

Application Insights

The automotive segment dominated the market in 2023, with a share of 34.1%. Components manufactured from liquid silicone rubber are lightweight, thus increasing fuel efficiency. They also reduce CO2 and NO2 emissions, which are air pollutants. Automotive applications of liquid silicone rubber include gaskets, LED headlights, windshield wiper blades, harness components, membranes, valves, seals, dampers, and other components. Therefore, the growing automotive sector and increasing vehicle demand have resulted in the market growth of this segment.

The electronic & electrical segment is projected to grow at a CAGR of 8.4% during the forecast period. Liquid silicone rubber is used in the electronics and electrical sectors to insulate, seal, and encapsulate electronic parts. Due to its properties, such as heat resistance, electricity, and chemical resistance, LSR is being utilized more in the production of electronic parts. The demand for liquid silicone rubber is rapidly increasing due to the growing electronics sector and the need for durable electronic devices.

Regional Insights

North America liquid silicone rubber market dominated the global market in terms of revenue share of 37.4% in 2023. North America has been a crucial market for liquid silicone rubber owing to its wide usage in several applications, including medical, automotive, construction, electronics, and others. Medical applications are expected to witness significant growth over the coming years.

Increased adoption of LSR in product manufacturing due to its properties such as heat resistance, chemical and electricity resistance, malleability, and more has resulted in market growth in this region.

U.S. Liquid Silicone Rubber Market Trends

The U.S. liquid silicone rubber market had a substantial market share of 87.4% in North America due to increased utilization of LSR in the production of products in sectors such as automobile, medical, construction, and more. The strong presence of the automotive and medical sectors has resulted in increased demand for LSR. Furthermore, the utilization of LSR in the electrical and electronics industry has also fueled the growth of this market in the U.S.

Europe Liquid Silicone Rubber Market Trends

Europe liquid silicone rubber market was identified as a lucrative region in this industry, as it had a market share of 24.4% in 2023. This growth resulted from increased utilization of LSR in industries such as automotive, construction, and medical. The automotive industry is integrating LSR in the production of vehicle parts due to its properties of high malleability and low weight. Hence, these factors aid in the market growth in this region.

UK Liquid Silicone Rubber Market Trends

The UK liquid silicone rubber market is expected to grow rapidly due to developments in the medical and automotive sectors and increased demand for LSR to manufacture various products in these industries. Growth in the medical sector has resulted in increased demand for medical devices made from LSRs to help avoid contamination and HAIs. Furthermore, vehicle parts made from LSR help reduce weight; hence, there is an increased demand for LSR in vehicle parts production in this country.

Asia Pacific Liquid Silicone Rubber Market Trends

Asia Pacific liquid silicone rubber market held a market share of 26.6% in 2023 owing to the growth in sectors such as automotive, medical, and construction. The presence of a high population in countries such as China, India, and Japan has resulted in increased demand for LSR-made products in the medical and automotive sectors. Major companies are investing heavily to launch new products and increase their market expansion in this region. Hence, these factors are responsible for the market growth in this region.

China Liquid Silicone Rubber Market Trends

China liquid silicone rubber market is anticipated to grow at a substantial rate over the forecast period. The factor responsible for the country's market growth is the presence of a developed manufacturing industry. Major companies in this country are integrating LSR in their production of various products as LSR is malleable, heat resistant, chemical, and electricity resistant. These properties of LSR have resulted in increased integration of LSR in manufacturing vehicle parts, electrical parts, medical devices, and more. Therefore, these factors have contributed to the growth of the liquid silicone rubber in this country.

Key Liquid Silicone Rubber Company Insights

Some of the major companies in the liquid silicone rubber market are Avantor Inc., Dow

Elkem ASA, and others. Companies are focusing on product development with the help of reseach and development, mergers and acquistions, and more. The companies are also integrating eco-friendly practices in order to promote carbon neutrality.

-

Avantor Inc. is a biotechnology research company. The company provides lab and production services in for domains such as biotechnology, chemical and pharmaceutical. The company specializes in products such as materials and consumables, silicones, and equipment and instrumentations.

-

Dow is a plastics company specialized in the production of plastics such as polyurethane, polyethylene, polypropylene, and synthetic rubber. The company also focuses on production of agricultural chemicals and Styrofoam.

Key Liquid Silicone Rubber Companies:

The following are the leading companies in the liquid silicone rubber market. These companies collectively hold the largest market share and dictate industry trends.

- Avantor Inc.

- Dow

- Elkem ASA

- Momentive Performance Materials

- SIMTEC Silicone Parts, LLC

- Shin-etsu Chemical Co. Ltd

- Stockwell Elastomerics

- Trelleborg AB

- Wacker Chemie AG

- Wynca Tinyo Silicone Co. Ltd

Recent Developments

-

In July 2023, Shin-etsu Chemical Co. Ltd announced an investment plan of worth nearly USD 640 million to improve its silicones portfolio. The investment was planned in order to mitigate the demand for the silicone products sold by the company. The company planned to expand its eco-friendly products portfolio in order to achieve the goal of carbon neutrality.

-

In December 2022, Dow announced the launch of a new product named SILASTIC SA 994X Liquid Silicone Rubber series. The goal of the product launch was to maintain the emphasis on safer and more sustainable technologies. The product consists primerless, self-adhesive LSRs that are self-lubricating. They have a one-to-one mix ratio and are designed for two-component injection molding with thermoplastic substrates.

Liquid Silicone Rubber Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 3.04 billion

Revenue forecast in 2030

USD 4.97 billion

Growth rate

CAGR of 8.5% from 2024 to 2030

Base year for estimation

2023

Historical data

2018 - 2022

Forecast period

2024 - 2030

Report updated

October 2024

Quantitative units

Revenue in USD Million, Volume in Kilotons and CAGR from 2024 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Grade, application, region

Regional scope

North America, Europe, Asia Pacific, Latin America, MEA

Country scope

U.S., Canada, Mexico, UK, Germany, France, Italy, Spain, China, India, Japan, Australia, South Korea, Brazil, Argentina, South Africa, Saudi Arabia

Key companies profiled

Avantor Inc.,Dow; Elkem ASA; Momentive Performance Materials; SIMTEC Silicone Parts, LLC; Shin-etsu Chemical Co. Ltd; Stockwell Elastomerics; Trelleborg AB; Wacker Chemie AG; Wynca Tinyo Silicone Co. Ltd

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

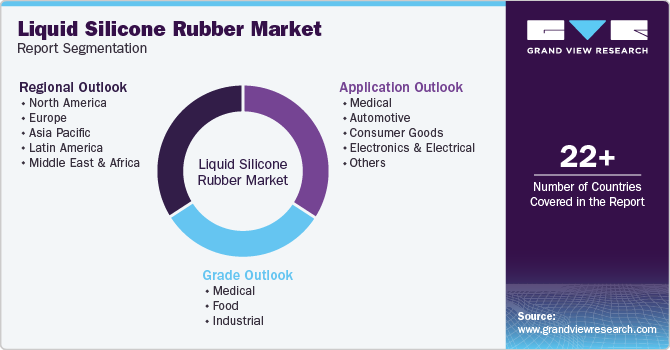

Global Liquid Silicone Rubber Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global liquid silicone rubber market report based on grade, application, and region:

-

Grade Outlook (Revenue, USD Million, Volume in Kilotons, 2018 - 2030)

-

Medical

-

Food

-

Industrial

-

-

Application Outlook (Revenue, USD Million, Volume in Kilotons, 2018 - 2030)

-

Medical

-

Automotive

-

Consumer Goods

-

Electronics & Electrical

-

Others

-

-

Regional Outlook (Revenue, USD Million, Volume in Kilotons, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

Australia

-

South Korea

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East and Africa (MEA)

-

Saudi Arabia

-

South Africa

-

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.