- Home

- »

- Medical Devices

- »

-

Mesh Nozzle Plates Market Size, Share, Growth Report 2030GVR Report cover

![Mesh Nozzle Plates Market Size, Share & Trends Report]()

Mesh Nozzle Plates Market (2025 - 2030) Size, Share & Trends Analysis Report By Material Type (Metal & Alloys, Engineered Plastics), By Application (Medical, Electronics), By Type of Manufacturing, By Region, And Segment Forecasts

- Report ID: GVR-4-68039-438-0

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Healthcare

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Report Overview

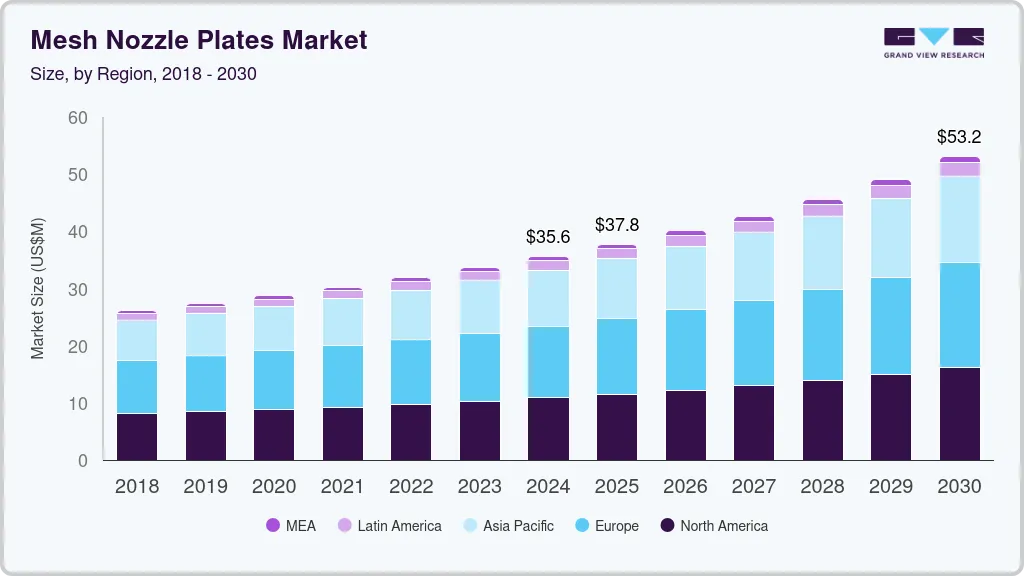

The global mesh nozzle plates market size was estimated at USD 35.6 million in 2024 and is estimated to grow at a compound annual growth rate (CAGR) of 7.1% from 2025 to 2030. Growing adoption of additive manufacturing processes, such as electroforming, demand for high-precision products, and the wide range of applications of mesh nozzle plates, are some of the key drivers of this market. Electroplating and laser cutting have been popular choices for manufacturing mesh nozzle plates. However, with growing technological advancements and increased demand for micro-manufacturing, electroforming has emerged as a viable and cost-effective option. Mesh nozzle plates for microparts used in mesh nebulizers and humidifiers are being increasingly produced through electroforming and this trend is expected to continue over the forecast period.

Veco B.V., for instance, offers a wide portfolio of electroformed products with micro holes as part of its precision products lineup. According to the company, electroforming as a type of additive manufacturing process offers several benefits, such as support for large-volume production, high precision, and perfect process control. The wide applicability of mesh nozzle plates is another key driver that impels market growth. This ranges from inkjet printers to fuel injectors and from mesh nebulizers to perfume diffusion, among others. Informatic Component Technology Ltd., for example, is a UK-based company specializing in inkjet printhead components including inkjet nozzle plates. With up to 256 micro holes, the company’s nozzle plates create an array of over 19 million droplets of ink per second.

The COVID-19 pandemic had a notable impact on the market for mesh nozzle plates as the pandemic fueled the demand for micro parts in essential medical devices, such as nebulizers and ventilators. In April 2020, Johnson Matthey Piezo Products supplied piezo-ceramic bending actuators, a vital ventilator component, to its customer, HOERBIGER Flow Control, as part of essential products shipment. However, the market growth was also negatively impacted by supply chain restrictions and a decrease in unit sales of the products. Exposed vulnerabilities in supply chains due to continuous lockdowns and unexpected changes in the availability of raw materials have nullified the efforts of manufacturers to improve operations.

Material Type Insights

On the basis of material types, the market has been further categorized into metals & alloys, engineered plastics, and others. The metals and alloys segment dominated the market for mesh nozzle plates and accounted for the largest revenue share of 39.47% in 2022. This is owing to the high durability and usage of metallic nozzle plates in a variety of industries. Aroma Sense USA, for instance, offers a range of steel spray plates intended as replacements for Aroma Sense Prestige showerheads.

The engineered plastics segment is projected to grow at the highest CAGR over the forecast period. The key factors responsible for this growth include the cost-effectiveness of the material and increasing R&D by market players to diversify their portfolios. Micro, based in Taiwan, for instance, markets a polyimide-based mesh for its nebulizer lineup, in addition to its other metallic mesh nozzle plates. The increased demand for cost-effective solutions is anticipated to boost the segment growth in the coming years.

Type of Manufacturing Insights

The others segment comprising electroplating and laser cutting dominated the market and accounted for the largest revenue share of more than 50.0% in 2022. The key factor contributing to this share includes widespread usage of these procedures in varied applications from industrial, printing, medical, and agriculture, to disinfection, automotive, and other sectors. The electroforming segment, on the other hand, is expected to register the highest CAGR over the forecast period. This is due to the rising adoption of electroforming techniques by the key players. Veco, headquartered in the Netherlands, is especially known for its chemical etching, electroforming, and laser material processing technologies.

Electroforming is a type of additive manufacturing process used for producing high-precision metal parts. Electroforming is an ideal manufacturing process for producing micro-precision nozzle plates because of its exceptional ability to create intricate and complex structures with a high degree of precision. The process consists of creating metal parts atom by atom with high accuracy and aspect ratios. According to AMFG, a workflow software company, North America and Europe regions lead the additive manufacturing market, due to the presence of key companies involved in developing, adopting, or investing in additive manufacturing. Supportive government initiatives, such as the launch of the National Additive Manufacturing Innovation Institute (NAMII), now rebranded as America Makes, helped boost the growth of the market for mesh nozzle plates in the U.S.

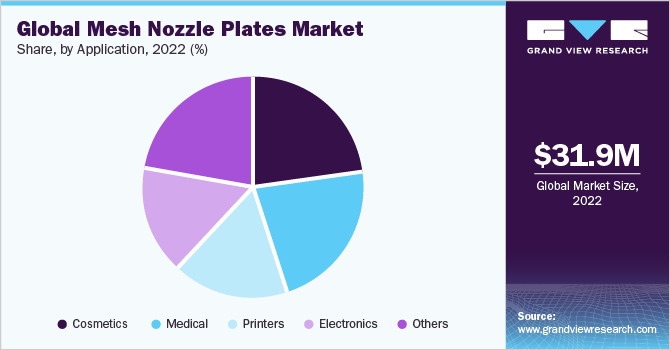

Application Insights

On the basis of applications, the global industry has been further categorized into cosmetics, medical, printers, and electronics. The cosmetics segment accounted for the largest revenue share of 22.6% in 2022. The cosmetics industry dominated the application segment owing to the increasing use of mesh nozzle plates in atomizers including humidifiers, diffusers, and perfumes, that require aerosolization of liquid into a fine mist.

The medical segment is projected to grow at the highest CAGR of 6.3% over the forecast period. This is due to an increase in the R&D of medical devices having micro-mesh parts. For example, vibration micro-mesh plates are expected to find wide applications in mesh nebulizers as the usage of mesh nebulizers for high-cost drugs and niche therapy increases over time. This is owing to the challenges presented by the delivery of drugs to mechanically ventilated patients. There is also an increased need for optimizing drug and device-related factors for effective drug delivery in ventilated patients.

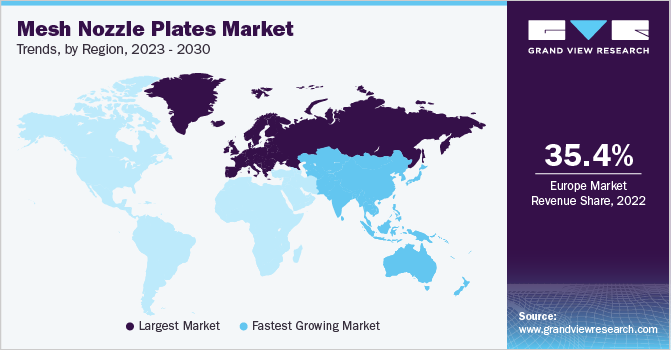

Regional Insights

Europe dominated the market and accounted for the largest revenue share of 35.4% in 2022. The growth can be attributed to the presence of key players, such as temicon GmbH, in the region and the high adoption of additive manufacturing technologies for the production of micro and macro components having large-scale industrial, cosmetic, and healthcare applications. temicon GmbH, is a German company, specializing in manufacturing metal micro parts, such as nozzle plates, for the nebulization of liquids. According to the International Trade Administration, and the U.S. Department of Commerce, Germany holds the position of being the largest additive manufacturing (AM) market in Europe, displaying impressive growth rates of up to 15 percent.

According to a recent study conducted by the European Patent Office, approximately 50% of all AM patents registered in Europe are attributed to Germany. Consequently, Germany boasts the largest and most dynamic additive manufacturing market within the European Union. In Asia Pacific, the market is estimated to grow at a lucrative CAGR of 6.3% owing to the presence of a large number of manufacturers, suppliers, and traders offering cost-effective mesh nozzle plates in bulk quantities in this region. Companies are also investing in product development and strengthening their distribution partnerships. This is expected to contribute to the regional market growth over the forecast period.

Key Companies & Market Share Insights

The market is highly competitive.Key players are undertaking strategic initiatives, such as customer acquisition and R&D in product innovation, to gain higher market share. Key players are also involved in strengthening their distribution network and portfolio diversification to widen product applications. For instance, Johnson Matthey offers a range of piezoelectric ultrasonic atomizers for medical healthcare applications, such as nebulizers, agricultural use, wellness, humidification, disinfection, and industry or cooling counters. Some of the prominent players in the global mesh nozzle plates market include:

-

temicon GmbH

-

Veco B.V.

-

Johnson Matthey

-

Microbase Technology Corp.

-

Informatic Component Technology Ltd.

-

Tekceleo

-

Piezo Direct

-

Dongguan Cosson Electronic Plastic Co., Ltd.

-

APC International, Ltd.

Mesh Nozzle Plates Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 37.8 million

Revenue forecast in 2030

USD 53.2 million

Growth rate

CAGR of 7.1% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Revenue in USD million, and CAGR from 2025 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Material type, type ofmanufacturing, application, region

Regional scope

North America; Europe; Asia Pacific; Latin America; MEA

Country scope

U.S.; Canada; UK; Germany, France; Italy; Spain; Denmark; Sweden; Norway; China; Japan; India; Australia; South Korea; Thailand; Brazil; Mexico; Argentina; Saudi Arabia; South Africa; UAE; Kuwait

Key companies profiled

temicon GmbH; Veco B.V.; Johnson Matthey; Microbase Technology Corp.; Informatic Component Technology Ltd.; Tekceleo; Piezo Direct; Dongguan Cosson Electronic Plastic Co., Ltd.; APC International, Ltd.

Customization scope

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

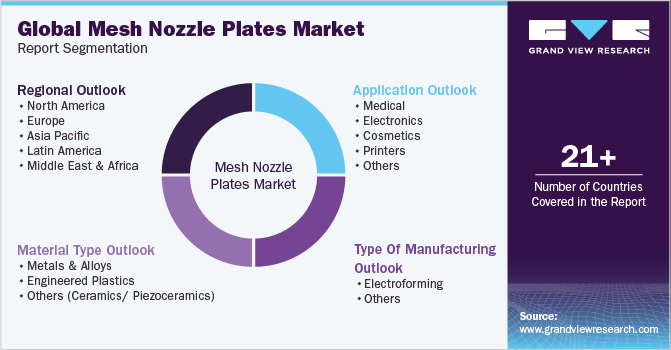

Global Mesh Nozzle Plates Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global mesh nozzle plates market report on the basis of material type, type of manufacturing, application, and region:

-

Material Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Metals and Alloys

-

Engineered Plastics

-

Others (Ceramics/ Piezoceramics)

-

-

Type of Manufacturing Outlook (Revenue, USD Million, 2018 - 2030)

-

Electroforming

-

Others

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Medical

-

Electronics

-

Cosmetics

-

Printers

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

Sweden

-

Norway

-

Denmark

-

-

Asia Pacific

-

China

-

Japan

-

India

-

Australia

-

Thailand

-

South Korea

-

-

Latin America

-

Brazil

-

Mexico

-

Argentina

-

-

Middle East and Africa

-

Saudi Arabia

-

South Africa

-

UAE

-

Kuwait

-

-

Frequently Asked Questions About This Report

b. The global mesh nozzle plates market size was estimated at USD 31.9 million in 2022 and is expected to reach USD 33.7 million in 2023.

b. The global mesh nozzle plates market is expected to grow at a compound annual growth rate of 5.8% from 2023 to 2030 to reach USD 50.0 million by 2030.

b. North America dominated the market for mesh nozzle plates and accounted for the largest revenue share of 30.6% in 2022.

b. Some key players operating in the mesh nozzle plates market include temicon GmbH; Veco B.V.; Maidencreek Manufacturing Sales, LLC; Johnson Matthey Piezo Products; MicroBase; Informatic Component Technology Limited; TEKCELEO; Piezo Direct; Dongguan Cosson Electronic Plastic Co., Ltd.; and APC International, Ltd.

b. Key factors driving the market growth include the growing adoption of additive manufacturing processes such as electroforming, demand for high precision products, and the wide usage of mesh nozzle plates from medical to industrial applications.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.