- Home

- »

- Advanced Interior Materials

- »

-

Metal Powder Market Size & Share, Industry Report, 2030GVR Report cover

![Metal Powder Market Size, Share & Trends Report]()

Metal Powder Market (2025 - 2030) Size, Share & Trends Analysis Report By Materials (Ferrous, Non-Ferrous), By Technology (Press & Sinter, Additive Manufacturing), By Application, By Region, And Segment Forecasts

- Report ID: GVR-3-68038-948-7

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Metal Powder Market Summary

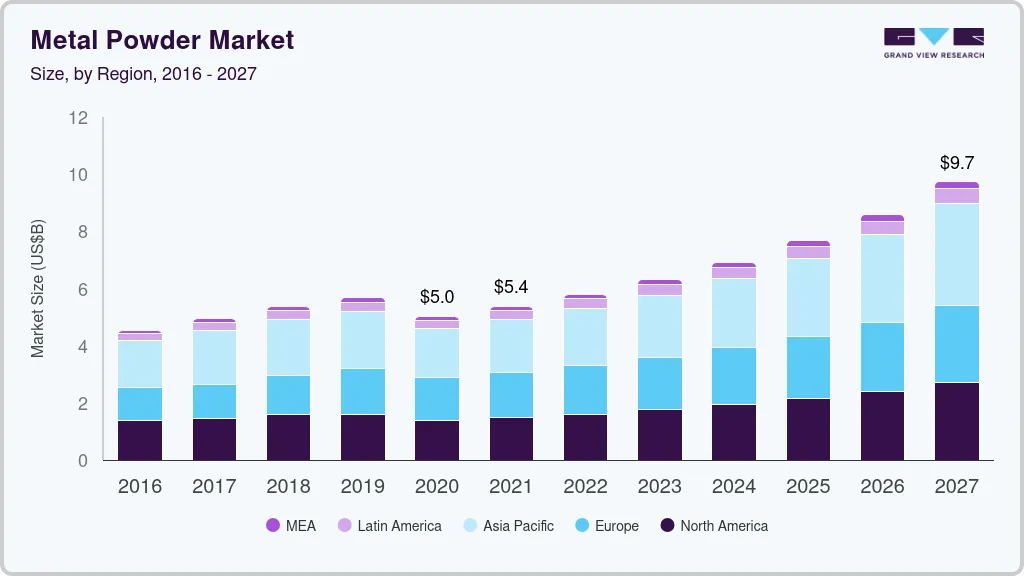

The global metal powder market size was estimated at USD 6.92 billion in 2024 and is projected to reach USD 10.18 billion by 2030, growing at a CAGR of 5.8% from 2025 to 2030. Increasing demand for additive manufacturing (AM) components from the aerospace industry is driving market growth.

Key Market Trends & Insights

- The North America metal powder industry is projected to expand at a growth rate of 5.7% from 2025 to 2030 in terms of revenue.

- The metal powder industry in the Asia Pacific held the largest global volume share in 2024, amounting to 35.0%.

- By material, ferrous was the largest segment and accounted for a revenue share of over 69.0% in 2024.

- By technology, the largest technology segment by volume was press and sinter, which accounted for more than 89.0% of the market in 2024.

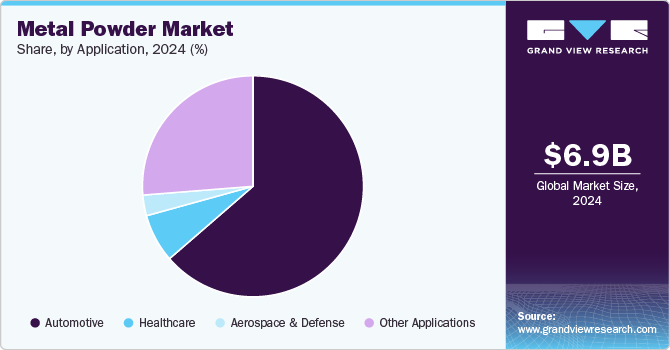

- By application, the automotive segment held the largest volume share of 64.9% in 2024.

Market Size & Forecast

- 2024 Market Size: USD 6.92 billion

- 2030 Projected Market Size: USD 10.18 billion

- CAGR (2025-2030): 5.8%

- Asia Pacific: Largest market in 2024

AM technology is an extremely reliable system, which enables the manufacturing of highly complex designs and geometries that cannot be made from other processes.Owing to an increase in demand for AM from aerospace & defense industries, key players are investing in expanding their capacity. For instance, in July 2023, Collins Aerospace announced that it is going to invest USD 14.0 million in the expansion of the AM facility.

Product-based components are extensively used in various end use industries, including automotive, industrial, electronics, firearms, and healthcare. Powder metallurgy can produce structural, magnetic, & next-generation high-performance parts and tribological components. Growth in end use industries is expected to propel demand for powdered parts in the U.S. during the forecast period.

Rising geopolitical tensions have pushed countries to increase and upgrade their aerospace & defense equipment, which is expected to augment consumption of the product over the forecast period. For instance, the German government has invested EUR 10 billion (USD 10.83 billion) to purchase F-35 fighter jets from the U.S.

The aerospace & defense segment is an early adopter of additive manufacturing (AM). Companies such as NASA, SpaceX, and other aerospace organizations are benefiting from AM technology as it facilitates the production of prototypes with high geometric accuracy in less time and ensures minimal wastage of material. Owing to the reasons above, several aerospace & defense companies are ordering metal AM printers.

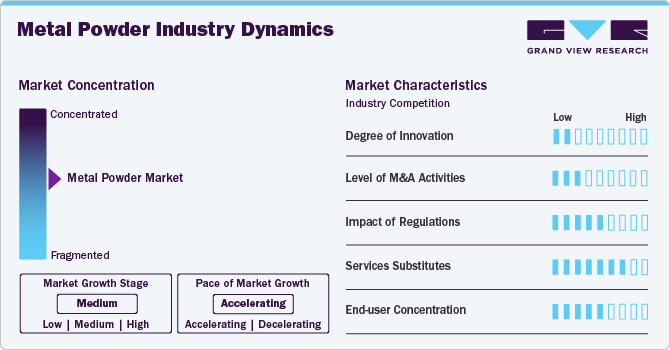

Market Concentration & Characteristics

The metal powder industry is characterized by the presence of established players, including GKN PLC, Sandvik AB, and Höganäs AB. Companies use an established distribution and sales network to connect with their customers across different regions. New product development and competitive pricing are some of the key focus areas for manufacturers to strengthen their position in the market.

Growth of lightweight vehicles, technological advancements, and raw material costs influence the price of products along with macroeconomic factors. Market players formulate their strategies in line with the above factors, along with the performance of key application industries, namely automotive, oil & gas, aerospace & defence, and medical.

Key players are using mergers and acquisitions activity across the globe, as large players acquire minority stakes in smaller producers that have advantages like advanced technology, efficient processes, or a solid presence in the market. Promotion of innovation, lower costs, and enhanced synergies within operations is also an essential element to enhance these activities in the industry.

The material used in AM to produce a wide range of end use products costs more than the material used in the traditional method. For instance, stainless steel as a raw material in AM costs over USD 8 per square centimetre compared to the ones used in traditional manufacturing. Thus, due to high cost of manufacturing acts as an AM market growth restraint.

Material Insights

Ferrous was the largest segment and accounted for a revenue share of over 69.0% in 2024. The segment encompasses a range of steel types and their alloys, along with iron and alloying elements such as molybdenum, nickel, and chromium. Steel is cost-effective and can be utilized in AM and blended with other materials, such as bronze.

The non-ferrous segment consists of aluminum, copper, zinc, titanium, tungsten, magnesium, and others. Aluminum's desirable traits, such as good strength and lightweight nature, are anticipated to increase its demand. It is widely used in the manufacturing of equipment, including functional parts and cycles. Aluminum-based equipment is produced using a 3D printing process called direct metal laser sintering.

Rising demand for titanium implants in the healthcare industry is projected to fuel the growth of this segment. To address deformities in the bones, human skull, and vertebrae, companies Novax DMA and CEIT Biomedical Engineering have started manufacturing medical implants made of titanium.

Technology Insights

The largest technology segment by volume was press and sinter, which accounted for more than 89.0% of the market in 2024. In the conventional powder metallurgy process, press and sinter are used. It is economic and produces near-net-shape components. Manufacturing a green compact involves heat treatment or compaction at temperatures lower than the melting point of the metal.

This mechanical bonding of particles contributes to increasing component strength. In addition, green compacts are sintered in a controlled atmosphere where they undergo metallurgical bonding to form their finished components. To attain accurate tolerances and a favorable finish of the surface, additional tasks such as plating, repression, or finishing can be carried out.

For the past 20 years, MIM technology has gained significant importance in the component industry. This process is based on shaping and sintering of particles similar to that used in the press or sinter. High volumes of complicated-shaped parts, with high manufacturing accuracy, can be produced through this method. There are different steps in the MIM process, e.g., mixing or processing of raw materials, injection molding, removal of bindery, and sintering.

Application Insights

The automotive segment held the largest volume share of 64.9% in 2024. In the automotive industry, various parts and components of engines, chassis, and transmissions are manufactured using powder metallurgy technology, which is propelling the demand for metal powder.

The aerospace & defense segment is an early adopter of the AM. This technology helps manufacturers to develop complex parts and prototypes. Hence, the aerospace and defense companies are purchasing new AM printers. For instance, in September 2023, GKN Aerospace ordered two 3D- 3D-printing systems from Nikon SLM Solutions.

The healthcare sector is driven by the increased awareness among consumers regarding various diseases and the rise in consumer willingness to pay more for end products. In addition, the application of metal powder technology in the health sector is driving this segment as it manufactures inserting plates, foot adapters, blacking plates, surgical blades, forceps, graspers, and Blacking Hooks.

Regional Insights

The North America metal powder industry is projected to expand at a growth rate of 5.7% from 2025 to 2030 in terms of revenue. In particular, demand for different sintered parts in transmissions and engines has been reduced due to the increasing popularity of vehicles that are both energy efficient and hybrid. Nevertheless, the market vendors are expected to have lucrative opportunities over the next few years through powder forging technology. According to the Federation of Metal Powder Industries, almost 30% of automotive coupling rods are produced through powder forging processes worldwide.

Asia Pacific Metal Powder Market Trends

The metal powder industry in the Asia Pacific held the largest global volume share in 2024, amounting to 35.0%. The region saw a high demand for products, mainly in the automotive and aviation sectors, in 2023. The region's market is being driven by the presence of small and midsized component producers for press and sintered products, coupled with increasing demand for AM.

Key Metal Powder Company Insights

Some of the key players operating in the market include GKN PLC and Sandvik AB:

-

GKN PLC is one of the leading producers and suppliers of the product, and it also produces atomized metal powders for various applications. The company annually produces around 250,000 tons of powder.

-

Sandvik AB has more than 45 years of expertise in metal powder and produces more than 400 different grades of alloys of metal powder alloys.

MolyWorks Materials Corporation, Inc. and Avimetal AM Tech Co., Ltd. are some of the emerging market participants in the industry.

-

MOLYWORKS Materials Corporation is among the emerging global manufacturers of sustainable metal powders. In 2015, the company invented “The Greyhound", a compact, alloy-agnostic, upcycling system. This system produces metal powder from metal waste streams of used powder, failed builds, old parts, and machined waste.

-

Avimetal AM Tech Co., Ltd, has advanced powder manufacturing technologies such as electrode induction gas automization, plasma automization, and vacuum induction gas automization.

Key Metal Powder Companies:

The following are the leading companies in the metal powder market. These companies collectively hold the largest market share and dictate industry trends.

- MolyWorks Materials Corporation

- Advanced Technology & Materials Co., Ltd

- GKN PLC

- Hoganas AB

- POLEMA

- Rio Tinto Metal Powders

- Rusal

- Sandvik AB

- CRS Holdings Inc.

- Liberty House Group Advanced Micro Devices

Recent Developments

-

In November 2023, 6K Additive acquired the Global Metal Powder company. This acquisition is expected to help the company in the expansion of refractory powder production and sustainable product development.

-

In October 2023, Sandvik AB announced that it is going to acquire Buffalo Tungsten, Inc. The acquisition is expected to allow Sandvik to increase its market presence in the U.S, as well as strengthen its regional capabilities within the component manufacturing value chain.

Metal Powder Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 7.66 billion

Revenue forecast in 2030

USD 10.18 billion

Growth rate

CAGR of 5.8% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative Units

Volume in kilotons, revenue in USD million, and CAGR from 2025 to 2030

Report coverage

Volume forecast, revenue forecast, competitive landscape, growth factors, and trends

Segments covered

Material, technology, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South Africa; Middle East & Africa

Country scope

U.S.; Germany; Italy; Spain; China; Japan; India; South Korea; Brazil

Key companies profiled

MolyWorks Materials Corporation; Advanced Technology & Materials Co., Ltd.; GKN PLC; Hoganas AB; POLEMA; Rio Tinto Metal Powders; Rusal; Sandvik AB; CRS Holdings Inc.; Liberty House Group

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

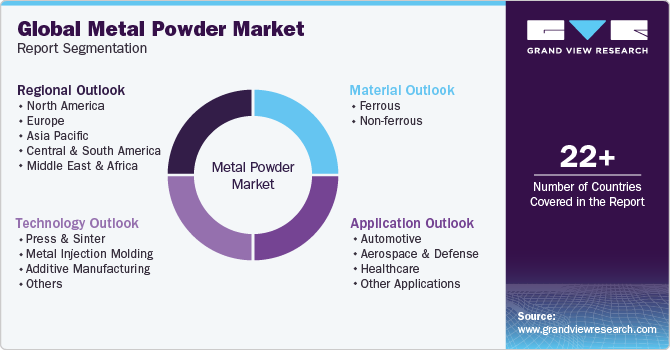

Global Metal Powder Market Report Segmentation

This report forecasts revenue and volume growth at the country & regional levels and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global metal powder market report based on material, technology, application, and region:

-

Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Ferrous

-

Non-ferrous

-

-

Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Press & Sinter

-

Metal Injection Molding

-

Additive Manufacturing

-

Others

-

-

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Automotive

-

Aerospace & Defense

-

Healthcare

-

Other applications

-

-

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

-

Europe

-

Germany

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

South Korea

-

India

-

-

Central & South America

-

Brazil

-

- Middle East & Africa

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.