- Home

- »

- Specialty Polymers

- »

-

Polychlorotrifluoroethylene Market Size & Share Report, 2030GVR Report cover

![Polychlorotrifluoroethylene Market Size, Share & Trends Report]()

Polychlorotrifluoroethylene Market (2025 - 2030) Size, Share & Trends Analysis Report By Application (Films, Wires & Tubes, Coatings, Others), By End-use (Pharmaceutical, Electrical & Electronics, Aerospace), By Region, And Segment Forecasts

- Report ID: GVR-2-68038-170-2

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Specialty & Chemicals

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Polychlorotrifluoroethylene Market Trends

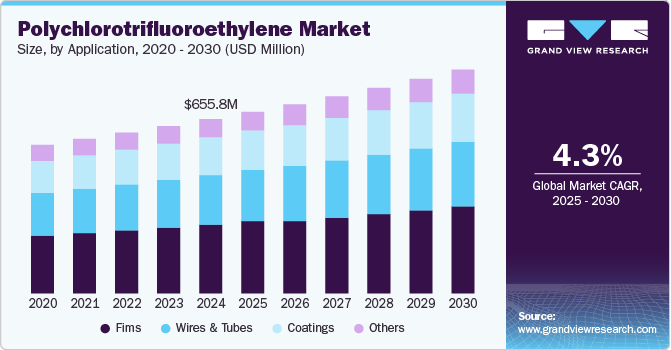

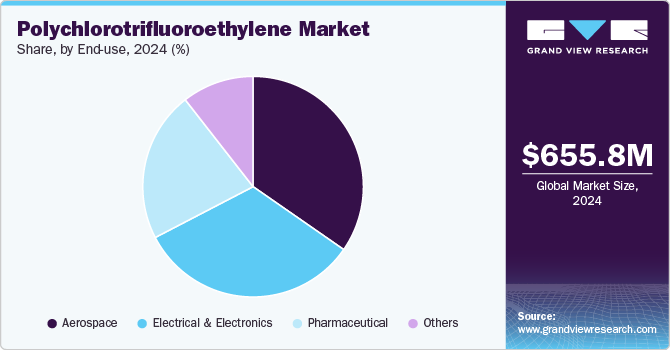

The global polychlorotrifluoroethylene market size was valued at USD 655.8 million in 2024 and is expected to grow at a CAGR of 4.3% from 2025 to 2030. Polychlorotrifluoroethylene (PCTFE) is extensively used in various application industries, such as aerospace, chemical processing, electronics, medical, pharmaceuticals, and others. Growing applications and innovation driven by technology advancements are expected to drive the growth of this market during the forecast period.

Polychlorotrifluoroethylene (PCTFE) is primarily utilized in manufacturing numerous products such as seals, valve seals, gaskets, pump parts, electric insulations, and laboratory instruments. Its high chemical resistance and ability to perform in extreme temperatures make it preferred as a material for laminating numerous polymers, such as polyvinyl chloride, polyethylene terephthalate glycol, and others.

Polychlorotrifluoroethylene (PCTFE) films have been experiencing higher demand owing to their application in developing moisture barriers, chemical barriers, electrical insulation, and lamination. These films are also used in the aerospace and military industry for packaging corrosion-sensitive components.

Polychlorotrifluoroethylene (PCTFE) has key properties such as high thermal stability, superior chemical resistance, and dimensional stability. These properties encourage the material's increasing utilization in products and solutions associated with systems and components often exposed to extreme environments.

In recent years, the pharmaceutical industry has embraced enhanced packaging strategies, which involve using flexible materials and structures for product packaging. Cost-effective packaging, performance-driven materials, and improved shelf life have become focus areas for numerous pharmaceutical companies. Properties such as moisture barriers have resulted in increasing utilization of Polychlorotrifluoroethylene (PCTFE) in the pharmaceutical industry for packaging applications.

Application Insights

The films segment dominated the global Polychlorotrifluoroethylene (PCTFE) industry with a revenue share of 39.5% in 2024. Polychlorotrifluoroethylene (PCTFE) films are extensively used in various applications, such as pharmaceutical blister packaging, chemical tank liners, and LCD panels. Properties offered by these films, such as chemical barriers, electrical insulation, and moisture barriers, primarily drive the growing demand. Polychlorotrifluoroethylene (PCTFE) films also provide insulation to sensitive electronic components. Growing demand for electronic equipment and increasing use of products such as transparent eyeglasses for casual and commercial use is adding to the growth experienced by this segment.

The wires & tubes segment is projected to experience a significant CAGR during the forecast period. This is attributed to the properties of this fluoropolymer, such as the lowest moisture absorption, non-flammability, superior electrical insulation, and low coefficient of thermal expansion. These properties have been stimulated using Polychlorotrifluoroethylene (PCTFE)-based wires and tubes in industries such as marine, chemical, electrical, aerospace, and others. The cryogenic and liquid gas applications are also adding to the growth opportunities.

End-use Insights

The aerospace segment held the largest revenue share of the global Polychlorotrifluoroethylene (PCTFE) industry in 2024. The aerospace industry uses polychlorotrifluoroethylene (PCTFE) to make components and parts frequently exposed to harsh environments, moisture, and chemicals. Material properties ensure enhanced performances and uninterrupted operations while offering an improved experience.

The electrical and electronics segment is expected to experience the highest CAGR from 2025 to 2030. This is attributed to the growing demand for electronic appliances and electrical products, for which Polychlorotrifluoroethylene (PCTFE) is extensively utilized for valves, seals, and electrical insulation. In recent years, rapid digitization and technological advancements have driven the demand for electronics at a lucrative rate. Electronic devices and appliances often engage in high-performance and commercial environments, where material properties, such as moisture barrier, insulation, and others, play vital roles.

Regional Insights

Asia Pacific dominated the global Polychlorotrifluoroethylene (PCTFE) industry with a revenue share of 45.4% in 2024. This market is primarily influenced by the increasing number of manufacturing units in the region for cost-effective labor, material availability, and multiple chemical industry participants in countries such as China. Polychlorotrifluoroethylene (PCTFE) is used in various innovation-driven industries such as medical devices, electronics, etc. The focus of multiple global companies on entering the Asia Pacific region for manufacturing operations and increasing accessibility to material is expected to drive the growth of this regional industry in the forecast period.

China Polychlorotrifluoroethylene Market Trends

China held the largest revenue share of the regional market in 2024. This is attributed to supportive government policies, favorable regulatory scenarios, and increasing demand for Polychlorotrifluoroethylene (PCTFE) utilized in various industries. China's Polychlorotrifluoroethylene market plays a significant role in the global supply chain operations.

Europe Polychlorotrifluoroethylene Market Trends

Europe was identified as one of the key regions of the global Polychlorotrifluoroethylene (PCTFE) industry in 2024. This market is mainly influenced by the robust presence of high-tech industries in the region, including aerospace, chemical processing, medical implants, and others. Regulations and quality standard requirements have recently stimulated Polychlorotrifluoroethylene (PCTFE) use. Recyclability offered by Polychlorotrifluoroethylene (PCTFE) also contributes to the growing utilization and growth experienced by this market.

The UK dominated the regional market for Polychlorotrifluoroethylene (PCTFE) in 2024. Some prominent industries in the country include industrial manufacturing, engineering, energy, healthcare, construction, technology, and others. These industries utilize Polychlorotrifluoroethylene (PCTFE) to provide electrical insulation, moisture barrier, and chemical barrier in their offerings. A strict regulatory scenario encourages the utilization of reliable materials such as Polychlorotrifluoroethylene (PCTFE) in these industries.

North America Polychlorotrifluoroethylene Market Trends

North America Polychlorotrifluoroethylene (PCTFE) industry is expected to experience a significant growth during the forecast period. The presence of numerous manufacturing businesses in the region, growing demand for high-performance materials in the aerospace industry, and increasing utilization of Polychlorotrifluoroethylene (PCTFE) owing to its superior chemical properties are expected to drive the growth of this market. Ease of availability facilitated by global collaborations and supplier contracts also increases growth opportunities.

The U.S. dominated the regional industry in 2024. This is attributed to factors such as the strong presence of industrial and advanced manufacturing industry in the country, increasing demand for Polychlorotrifluoroethylene (PCTFE) films, wire, and tubes from the electrical and electronic industry, and growing utilization of Polychlorotrifluoroethylene (PCTFE) by pharmaceutical and defense industry for innovation-based packaging.

Key Polychlorotrifluoroethylene Companies:

The following are the leading companies in the polychlorotrifluoroethylene market. These companies collectively hold the largest market share and dictate industry trends.

- DAIKIN INDUSTRIES, Ltd.

- Honeywell International Inc.

- Arkema

- HaloPolymer

- DuPont

- Solvay

- Zhejiang Juhua Co., Ltd.

- Akzo Nobel N.V.

- SAINT-GOBAIN

- Everflon Fluoropolymers

- Shanghai Huayi 3F New Materials Co., Ltd.

- AGC Chemicals

- The Chemours Company

- Welch Fluorocarbon Inc.

Key Polychlorotrifluoroethylene Company Insights

Some of the key companies operating in the global Polychlorotrifluoroethylene (PCTFE) industry include 3M, Honeywell International Inc., DuPont de Nemours, Inc., DAIKIN INDUSTRIES, Ltd., Saint-Gobain S.A., and others. To address increasing demand driven by growing applications, companies have been embracing strategies such as innovation, acquisitions and mergers, collaborations, and others.

-

Honeywell International Inc. primarily operates in four business segments: performance materials, safety and productivity solutions, aerospace, and automation. It offers polychlorotrifluoroethylene (PCTFE) films characterized by industrial-grade capabilities. Its portfolio includes HydroBlock 22a, P-series FC film, P-series HS film, PS series film, and P-series TR film.

-

DAIKIN INDUSTRIES, Ltd. offers products such as polymer and elastomer, surface modifications, specialty chemicals, and others. Its portfolio features NEOFLON PCTFE M-Series, which is extensively used in electronic components, semiconductors, and pump parts.

Polychlorotrifluoroethylene Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 683.1 million

Revenue forecast in 2030

USD 842.0 million

Growth Rate

CAGR of 4.3% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Revenue in USD million and CAGR from 2025 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Application, end-use, region

Regional scope

North America; Asia Pacific; Europe; Latin America; Middle East and Africa.

Country scope

U.S.; Canada; Mexico; Germany; UK; France; Italy; China; India; Japan; Australia; South Korea Brazil; UAE; Saudi Arabia

Key companies profiled

DAIKIN INDUSTRIES, Ltd.; Honeywell International Inc.; Arkema; HaloPolymer; DuPont; Solvay; Zhejiang Juhua Co., Ltd.; Akzo Nobel N.V.; SAINT-GOBAIN; Everflon Fluoropolymers; Shanghai Huayi 3F New Materials Co., Ltd.; AGC Chemicals; The Chemours Company; Welch Fluorocarbon Inc.

Customization scope

Free report customization (equivalent to 8 analyst working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Polychlorotrifluoroethylene Market Report Segmentation

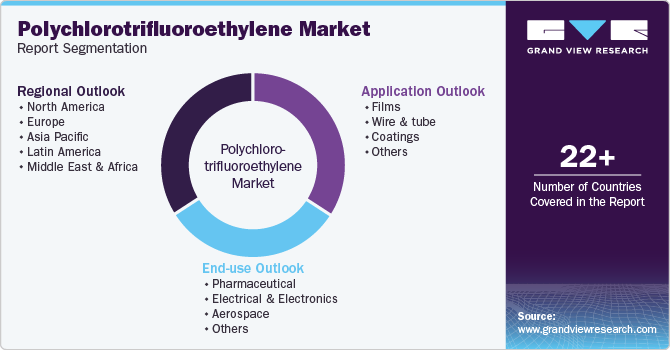

This report forecasts revenue growth at global, regional, and country levels and analyzes the latest industry trends in each sub-segment from 2018 to 2030. For this study, Grand View Research has segmented the global polychlorotrifluoroethylene market report based on application, end-use, and region:

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Films

-

Wire & tube

-

Coatings

-

Others

-

-

End-use Outlook (Revenue, USD Million, 2018 - 2030)

-

Pharmaceutical

-

Electrical & Electronics

-

Aerospace

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

-

Asia Pacific

-

China

-

India

-

Japan

-

Australia

-

South Korea

-

-

Latin America

-

Brazil

-

-

MEA

-

UAE

-

Saudi Arabia

-

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.