- Home

- »

- Plastics, Polymers & Resins

- »

-

Polyether Ether Ketone Market Size & Share Report, 2030GVR Report cover

![Polyether Ether Ketone Market Size, Share & Trends Report]()

Polyether Ether Ketone Market (2024 - 2030) Size, Share & Trends Analysis Report By Product (Unfilled, Carbon Filled, Glass Filled), By Application (Medical, Automotive, Aerospace, Electric & Electronic), By Region, And Segment Forecasts

- Report ID: 978-1-68038-381-2

- Number of Report Pages: 120

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2031 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Polyether Ether Ketone Market Summary

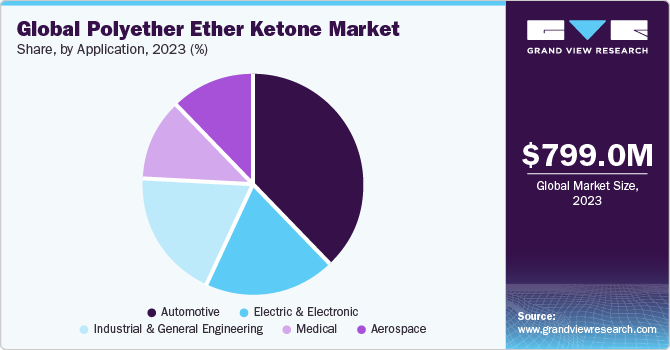

The global polyether ether ketone market size was estimated at USD 799.0 million in 2023 and is projected to reach USD 1,329.8 million by 2030, growing at a CAGR of 8.0% from 2024 to 2030. The growth in the automotive, aerospace, electronics, and medical industries has created various new applications for the product, which is contributing to the development of the polyether ether ketone (PEEK) market.

Key Market Trends & Insights

- North America dominated the global polyether ether ketone market with the largest revenue share in 2023.

- By product, the carbon-filled PEEK segment led the market, holding the largest revenue share in 2023.

- By application, the automotive segment led the market, holding the largest revenue share in 2023.

Market Size & Forecast

- 2023 Market Size: USD 799.0 Million

- 2030 Projected Market Size: 1,329.8 Million

- CAGR (2024-2030): 8.0%

- North America: Largest market in 2023

Similarly, the growing adoption of PEEK for industrial and general engineering applications is fueling global market growth.

PEEK possesses excellent characteristics that are widening the application scope such as e increasing product lines in transportation, semiconductors, industrial, food, and clinical areas. Over the forecast period, PEEK is anticipated to enter diverse markets and explore opportunities in untapped markets on account of its environment-friendly characteristics, including lower harmful emissions.

Polyether ether ketone (PEEK) plastics are widely used in the automotive industry, due to their excellent mechanical strength, impact resistance, and abrasion resistance, even at high temperatures. Similarly, it can withstand various corrosive chemicals, solvents, and lubricants.Furthermore, the demand for PEEK in the electrical & electronics segment is driven by the growing proliferation of electronic devices. PEEK can maintain good electrical insulation even under harsh conditions, such as high temperature, pressure, and humidity. It is widely used in the semiconductor industry due to its high purity and stable mechanical & chemical properties.

Over the forecast period, the market is anticipated to experience huge demand for PEEK products in medical applications. Currently, it is used for spinal surgery purposes and is expected to be used for more clinical applications and commercial medical products. PEEK is commonly used in orthopedic implants, such as spinal fusion cages, joint replacements, and trauma fixation plates. Its mechanical properties are similar to those of bones, making it an ideal material for load-bearing applications.

Favorable government policies for encouraging lightweight materials application in various industries, including automotive, medical, and construction, are expected to support the demand for polyether ether ketone over the forecast period. Several regulations are driving the preference for lighter vehicles as automotive light-weighting helps achieve the three aforementioned objectives. PEEK has emerged as a significant upgrade over metals in not only reducing the emission levels but also increasing fuel economy.

Market Concentration & Characteristics

The market is moderately fragmented, with key participants involved in R&D and technological innovations. Notable companies include Victrex plc, Caledonian Industries Ltd., Celanese Corporation, Saudi Basic Industries Corporation (SABIC), and Parkway Products, LLC among others. Several players are engaged in framework development to improve their market share.

The PEEK market is characterized by a moderate level of product substitutes. PEEK is emerging as an environment-friendly solution in various applications as its usage leads to the least amount of carbon emissions as compared to other polymers including ABS, polyester laminate, polyvinyl chloride, polystyrene, and polysulphone. PEEK increases the service life of the products in which it is used by providing excellent corrosion resistance. In comparison to other polymers, PEEK has the lowest fire, toxic emissions, and smoke rates. PEEK-based electrical wire bundle clamps are used in hydraulic tubing and wiring to manage and control aircraft systems.

Furthermore, the TPV market is moderately innovative. The key market players are increasingly developing innovative solutions to consolidate their position while being highly competitive. For instance, in October 2023, Victrex plc, a global PEEK manufacturer, announced the launch of a product grade of PEEK, Victrex Pharmaceutical Contact 101 (VICTREX PC 101). This product is designed to cater to the specific demands for non-implantable pharmacological contact and drug delivery device applications. This launch is aimed at strengthening Victrex's position in the pharmaceutical and drug delivery device markets, providing customers with innovative solutions for their specific needs.

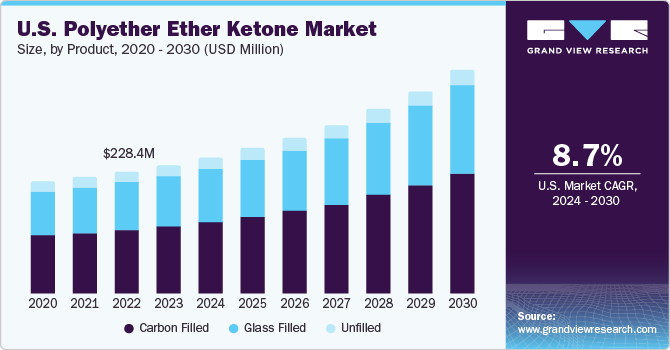

Product Insights

The carbon filled PEEK held the largest share of 46.9% in 2023 and is characterized by the inherent properties of the material. Carbon-filled PEEK are widely used as fillers owing to their high strength and inherent properties such as low thermal expansion, modulus, creep resistance, and corrosion resistance. Adding carbon fibers (CF) to PEEK lowers its expansion rate and increases the load-carrying capacity of PEEK-based composites. CF/PEEK laminates provide 3.5 times higher thermal conductivity than reinforced PEEK, thereby allowing better heat dissipation. This results in improved material capability and load-bearing capacity.

The glass filled PEEK segment is anticipated to witness substantial growth over the forecast period. Glass filled PEEK is widely utilized in the interior, under-the-hood components, electrical connectors, and applications such as thrust washers, bearings, seal rings, shift fork wear pads, bushings, and gears, owing to its high mechanical and thermal properties. In addition, 30% glass filled PEEK is the most common type of PEEK utilized in several structural applications owing to its characteristics such as high stiffness, stability, and strength.

Application Insights

In terms of revenue, automotive emerged as the largest application segment with a market share of over 37% in 2023, and this trend is projected to continue over the forecast period. Rising demand for lighter, smaller, and more consistent components, which are made from materials with excellent strength and high-temperature resistance compared to metals, is benefitting the growth of the PEEK market as the product possesses the aforementioned properties.

Aerospace application is expected to grow at a significant CAGR over the forecast period. PEEK finds extensive utilization in many applications in the aerospace sector as it is highly resistant against extreme temperatures. The product can be advantageous in engine cowling and has been applied in the Boeing 757-200 for the same purpose. It is also helpful in achieving substantial cuts in modern day aircraft by freeing up payload space. Thus, aerospace industry offers huge growth prospects for PEEK polymers.

Moreover, PEEK is widely used in several industrial and general engineering applications owing to its excellent physical and chemical properties. PEEK has the ability to withstand the pressure and heat generated in oil & gas industry. Thus, it finds wide-scale applications in making connector bodies, flappers, valve seats, compressor valve components, seals, flappers, and frac balls. To provide additional pressure resistance, PEEK is reinforced with carbon and glass, which prevents it from becoming unstable under extreme pressure in metal processing.

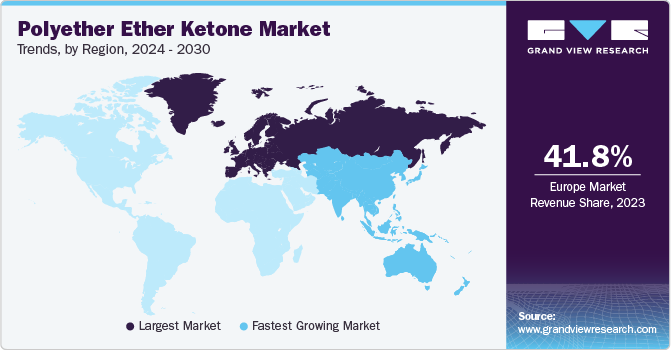

Region Insights

The North America PEEK market is projected to witness strong growth over the forecast period owing to the developed automotive and electronics industries and the growing aerospace industry. The presence of prominent automobile manufacturers, such as Chrysler, Tesla, Ford, and Cadillac, in this region and government initiatives in the defense and aircraft manufacturing industries are expected to propel the market in the coming years. Low tariffs and production costs on account of the wide reach of the country’s free-trade agreements are also expected to contribute to market growth.

U.S. Polyether Ether Ketone (PEEK) Market Trends

The PEEK Market in the U.S. held the largest share in the region in 2023. The U.S. enjoys several advantages in the evolving flexible electronics technology field. The country has the best and largest research universities across the globe, most of which are engaged in research & development projects related to the development of flexible electronics in the U.S.

Asia Pacific Polyether Ether Ketone (PEEK) Market Trends

Asia Pacific is expected to be the fastest-growing market over the forecast period. Supportive government policies in the region are encouraging global PEEK marketers to set up manufacturing and distribution facilities in this region. Economic growth in developing economies, such as China and India, is leading toward the creation of a wealthy urban class. This situation has boosted the sales of standard products, such as electronic goods, in these regions.

Polyether Ether Ketone (PEEK) Market in China led the market in 2023. The PEEK market in China is anticipated to witness promising growth over the forecast period. Healthy growth among the key manufacturing industries, including automotive and industrial & general engineering, is likely to contribute substantially to the ascending demand for PEEK in China.

India Polyether Ether Ketone (PEEK) Market is projected to witness a substantial growth over the forecast period. The demand for PEEK in India is primarily driven by the electrical & electronics sector, which is growing at a significant growth rate. India has the second-largest population in the world. Economic development in the country is equipping the population with a higher disposable income.

Europe Polyether Ether Ketone (PEEK) Market Trends

Europe dominated the polyether ether ketone (PEEK) market in 2023 with a revenue market share of over 41% and is projected to register a steady CAGR over the forecast period. This growth is attributed to the development of electric vehicles (EVs) and the presence of established printing and labeling markets. Composites containing PEEK are considered heat resistant, exhibit excellent strength, and insulation properties, and, therefore, are widely used in automotive applications.

Polyether Ether Ketone (PEEK) Market in Germany dominated the region in 2023. In terms of production and sales, Germany is the leading automotive market in Europe. The automotive industry in Germany is projected to grow prominently on account of the presence of a top-class technological environment, infrastructure, dynamic investment opportunities, and international research facilities, thus, posing lucrative growth opportunities for the PEEK market in the country.

The UK Polyether Ether Ketone (PEEK) Market is poised to grow at a significant CAGR through the forecast period. The UK PEEK market is expected to witness high investments by OEMs, due to increasing spending by automotive manufacturers for novel materials like PEEK, which offer lower weight and high specific strength to develop cost-effective component solutions with enhanced efficiency and performance.

Central & South America Polyether Ether Ketone (PEEK) Market Trends

The Central & South America PEEK market is progressing at a significant growth rate owing to the ongoing developments in the electronics and automotive industries. The electronics industry is attracting global investors owing to industrial development across vertical markets, and economic growth in the region.

Middle East & Africa Polyether Ether Ketone (PEEK) Market Trends

The PEEK market in MEA has rebounded in recent years. The region is projected to continue to witness positive growth in the PEEK demand with the lifting of economic sanctions in Iran and the drive for economic diversification between the oil-exporting countries of the Gulf Cooperation Council.

Key Polyether Ether Ketone Companies:

The following are the leading companies in the polyether ether ketone market. These companies collectively hold the largest market share and dictate industry trends.

- Victrex plc

- Caledonian Industries Ltd.

- Celanese Corporation

- Saudi Basic Industries Corporation (SABIC)

- Parkway Products, LLC

- A. Schulman, Inc. (LyondellBasell Industries Holdings B.V.)

- J.K. Overseas

- Cytec Solvay Group

- Evonik Industries AG

- Ensinger GmbH

Key Polyether Ether Ketone Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

-

In October 2023, Evonik Industries AG, a specialty chemicals company, launched innovative carbon-fiber-reinforced PEEK filaments, namely VESTAKEEP iC4620 3DF and VESTAKEEP iC4612 3DF, for long-term 3D printed medicinal implants. The filaments come in two grades, featuring 20% and 12% carbon fiber content, respectively, providing a choice of material based on the required strength and flexibility of 3D-printed implants. The carbon-fiber-reinforced PEEK filaments offer ductility, high strength, and low weight, making it an ideal metal-free alternative for implants. The alignment of carbon fibers can be controlled during the 3D printing process, and the filaments are compatible with standard extrusion-based 3D printing processes including fused filament fabrication (FFF).

Polyether Ether Ketone Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 840.2 million

Revenue forecast in 2030

USD 1.33 billion

Growth rate

CAGR of 8.0% from 2024 to 2030

Historical data

2018 - 2023

Forecast period

2024 - 2030

Report updated

June 2024

Quantitative Units

Volume in Tons, Revenue in USD million, and CAGR from 2024 to 2030

Report coverage

Volume forecast, Revenue forecast, competitive landscape, growth factors, and trends

Segments covered

Product, application, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; UK; France; Italy; Japan; China; India; South Korea; Taiwan; Brazil; Saudi Arabia

Key companies profiled

Victrex plc; Caledonian Industries Ltd.; Celanese Corporation; Saudi Basic Industries Corporation (SABIC); Parkway Products, LLC; A. Schulman, Inc. (LyondellBasell Industries Holdings B.V.); J.K. Overseas; Cytec Solvay Group; Evonik Industries AG; Ensinger GmbH

Customization scope

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Polyether Ether Ketone Market Report Segmentation

This report forecasts revenue growth at the global, regional, and country levels and provides an analysis of the latest industry trends and opportunities in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global Polyether Ether Ketone (PEEK) Market report based on product, application, and region:

-

Product Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Unfilled

-

Carbon filled

-

Glass filled

-

-

Application Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

Medical

-

Automotive

-

Aerospace

-

Industrial and General Engineering

-

Electric & Electronic

-

-

Regional Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

-

Asia Pacific

-

Japan

-

China

-

India

-

South Korea

-

Taiwan

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Saudi Arabia

-

-

Frequently Asked Questions About This Report

b. The global polyether ether ketone market size was estimated at USD 799.0 million in 2023 and is expected to reach USD 840.2 million in 2024.

b. The global polyether ether ketone market is expected to grow at a compound annual growth rate of 8.0% from 2024 to 2030 to reach USD 1,329.8 million by 2030.

b. The carbon-filled segment dominated the polyether ether ketone market with a share of 46.9% in 2023. This is attributable to increasing automotive, aerospace, and medical applications.

b. Some key players operating in the PEEK market include Victrex Plc; Panjin Zhongrun High-Performance Polymers Co. Ltd; Jrlon Inc.; Celanese Corporation, SABIC, A. Shulman, Inc., J.K. Overseas and Quadrant EPP Surlon India Ltd.

b. Key factors that are driving the market growth include increasing demand from semiconductors, industrial, food, clinical application and rising demand for light-weight and fuel-efficient vehicles.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.