- Home

- »

- Advanced Interior Materials

- »

-

U.S. Twin Screw Extruders Market Size & Share Report, 2033GVR Report cover

![U.S. Twin Screw Extruders Market Size, Share & Trends Report]()

U.S. Twin Screw Extruders Market (2025 - 2033) Size, Share & Trends Analysis Report By Product (Co-rotating Twin Screw Extruders, Counter-rotating Twin Screw Extruders), By End Use (Plastic & Polymer Processing, Food Processing, Pharmaceutical, Rubber), And Segment Forecasts

- Report ID: GVR-4-68040-688-2

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2021 - 2024

- Forecast Period: 2025 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

U.S. Twin Screw Extruders Market Summary

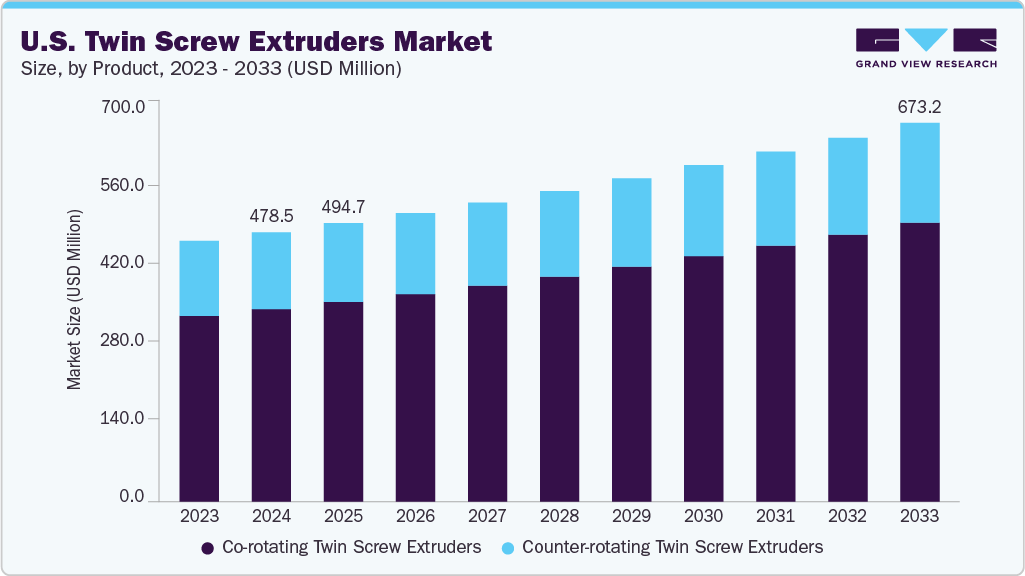

The U.S. twin screw extruders market size was estimated at USD 478.5 million in 2024 and is projected to reach USD 673.2 million by 2033, growing at a CAGR of 3.9% from 2025 to 2033. The growth is attributed to a well-established manufacturing base across the plastics, food, and pharmaceutical industries.

Key Market Trends & Insights

- The twin screw extruders market in the U.S. is expected to grow at a substantial CAGR of 3.9% from 2025 to 2033.

- By product, the co-rotating twin screw extruders segment is expected to grow at a considerable CAGR of 4.3% from 2025 to 2033.

- By end use, the pharmaceutical segment is expected to grow at a considerable CAGR of 5.2% from 2025 to 2033.

Market Size & Forecast

- 2024 Market Size: USD 478.5 Million

- 2033 Projected Market Size: USD 673.2 Million

- CAGR (2025-2033): 3.9%

Companies are increasingly investing in twin screw systems due to their superior output quality, energy efficiency, and ability to handle complex material formulations. Additionally, the focus on sustainable manufacturing and recycling initiatives in the U.S. is boosting demand for twin screw extruders in plastic waste reprocessing. Government regulations promoting circular economy practices and investment in modern extrusion technologies by local processors are further supporting market growth.

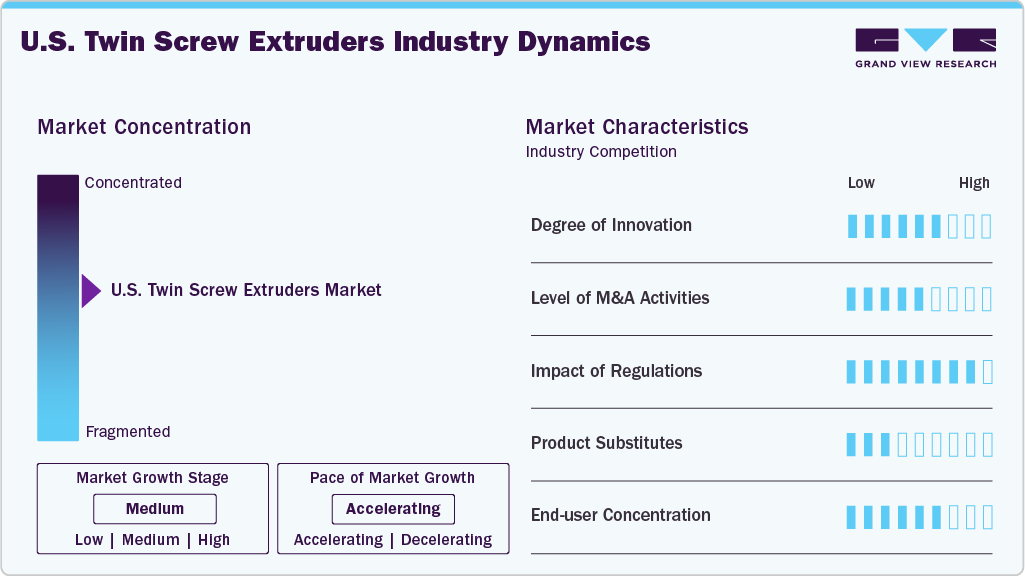

Market Concentration & Characteristics

The U.S. twin screw extruders market is moderately concentrated, with a few key players holding significant market shares. Established companies leverage strong distribution networks, advanced R&D, and long-standing customer relationships. However, regional and specialized manufacturers also compete by offering customized solutions. This balance creates a competitive yet stable market structure.

The U.S. twin screw extruders market exhibits a high degree of innovation, driven by demand for precision processing and material versatility. Companies are investing in digital control systems, energy-efficient designs, and modular configurations. Innovation is also focused on improving throughput and processing of bioplastics. These advancements help manufacturers meet evolving end-user requirements.

The market sees a moderate level of mergers and acquisitions, aimed at expanding technological capabilities and geographic presence. Larger firms often acquire niche players to access proprietary designs or specialized application areas. M&A activity also enables quicker entry into high-growth segments like recycled materials. This trend contributes to market consolidation and stronger competition.

Regulations in the U.S. strongly influence the twin screw extruder market, especially around safety, emissions, and plastic recycling standards. Compliance with FDA and EPA norms drives equipment upgrades and innovation. Sustainability policies are encouraging the adoption of extruders capable of processing biodegradable and recycled materials. These regulatory shifts shape both demand patterns and product development.

Drivers, Opportunities & Restraints

Rising demand for customized plastic compounds in the automotive, consumer goods, and packaging sectors is driving the U.S. twin screw extruders market. Technological advancements enabling efficient processing of complex materials are also fueling growth. Increased focus on recycling and sustainable production supports adoption. The market benefits from domestic manufacturing expansion and innovation.

There is a significant opportunity in developing energy-efficient and digitally controlled extruders tailored to niche applications. Growth in bioplastics and recycled plastic processing presents untapped potential. Expansion of the medical and food sectors also creates demand for specialized extrusion systems. Strategic partnerships and after-sales service offerings can further boost competitiveness.

High initial investment and maintenance costs remain major barriers for small and mid-sized processors. Technical complexity in handling varied materials can also limit adoption. Supply chain disruptions for specialized components may affect production timelines. Additionally, slower adoption of automation in certain traditional industries could hinder market growth.

Product Insights

Co-rotating twin screw extruders dominated the U.S. market and accounted for 71.5% revenue share in 2024, due to their superior mixing capabilities and consistent processing output. These systems are widely used in industries such as plastics, food, and pharmaceuticals for compounding, blending, and devolatilization. Their ability to handle a wide range of formulations with high throughput makes them a preferred choice among U.S. manufacturers. Advanced features like self-wiping screws and modular design enhance their appeal. Their dominance is reinforced by continuous innovation and strong demand for high-performance applications.

Counter-rotating twin screw extruders are gaining traction in the U.S. due to their effectiveness in PVC processing and applications requiring high-pressure buildup. They are especially useful in profile extrusion and medical tubing, where precision and dimensional stability are critical. The market is witnessing increased investment in this segment, driven by demand for durable and lightweight materials. Improved screw designs and automation are also boosting adoption. As manufacturers seek application-specific solutions, this segment is expected to see steady growth.

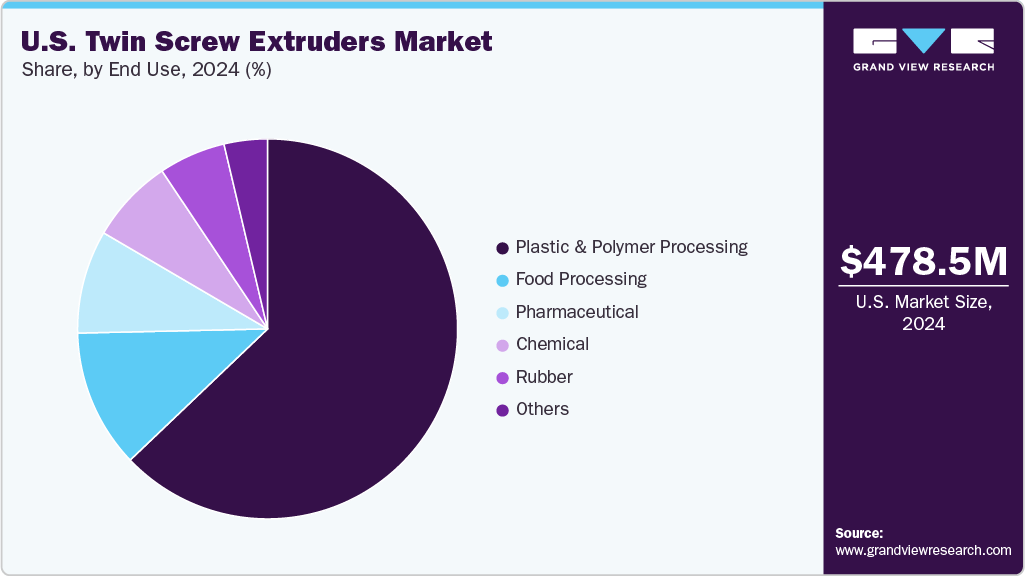

End Use Insights

The plastic & polymer processing segment accounted for a revenue share of 63.0% in 2024 due to strong demand from the automotive, packaging, and consumer goods industries. Manufacturers rely on twin screw extruders for efficient blending, compounding, and color masterbatch production. The growing emphasis on lightweight and high-performance materials further supports segment dominance. Additionally, increased use of recycled plastics and biopolymers is expanding the scope of twin screw extrusion in this sector. Continuous technological upgrades keep this segment at the forefront of market demand.

The pharmaceutical segment is expected to grow fastest in the U.S. twin screw extruders market over the forecast period due to rising demand for continuous manufacturing and precision drug formulation. Twin screw extruders enable superior control over drug mixing, granulation, and hot melt extrusion. Regulatory encouragement from the FDA for continuous processing methods is accelerating adoption. Moreover, the need for customized drug delivery systems and solid dosage forms is boosting investments in extrusion technologies. This trend is creating new growth avenues for specialized equipment manufacturers.

Key U.S. Twin Screw Extruders Company Insights

Some key players operating in the market include Coperion GmbH, KraussMaffei Group, and Leistritz Extrusionstechnik GmbH.

-

Coperion GmbH specializes in manufacturing high-performance twin screw extruders used across plastics, chemicals, food, and pharmaceutical industries. Their ZSK series co-rotating twin screw extruders are known for superior mixing, compounding, and devolatilization capabilities. The company also offers material handling systems, feeders, bulk solids handling equipment, and complete extrusion lines. Coperion supports custom system integration and advanced control solutions for continuous manufacturing processes. Their technologies are tailored for both standard and highly specialized processing requirements.

-

KraussMaffei Group provides a comprehensive range of twin screw extruders, particularly for applications in PVC, polyolefins, and engineering plastics. Their ZE BluePower series focuses on high-performance compounding with energy-efficient designs and precise temperature control. In addition to extrusion systems, the company delivers injection molding and reaction process machinery. They also offer complete downstream solutions, automation systems, and digital service platforms. KraussMaffei caters to diverse sectors including automotive, construction, medical, and electronics.

Key U.S. Twin Screw Extruders Companies:

- Coperion GmbH

- KraussMaffei Group

- Leistritz Extrusionstechnik GmbH

- Davis Standard.

- Bühler Group

- Milacron

- Baker Perkins

- CPM Extrusion Group

- Thermo Fisher Scientific Inc.

- WENGER MANUFACTURING

Recent Developments

-

In July 2025, Coperion introduced its digital platform C‑BEYOND at colorplasticchemie to enable real-time monitoring of ZSK extruders. The system tracks performance, energy use, and emissions to improve planning and maintenance. It also helps reduce downtime and optimize production. Coperion will present it at K 2025 in Düsseldorf.

-

In January 2025, Useon partnered with the National Fund for Innovation to boost its machinery development. The deal includes issuing new shares to support advanced extruder and pelletizer production. This move aims to strengthen Useon’s industrial capabilities. It marks a key step in scaling up innovation and growth.

-

In October 2024, Xtrutech introduced the XTSXP‑19 high-powered laboratory twin-screw extruder, a major technological leap featuring 100% increased motor power (7.8 kW), up to 1,200 rpm screw speed, and barrel bores of 19 mm and 24 mm for lab-scale applications. Designed to tackle demanding processes in biopolymers, plastics, food, and powder coating, the XTSXP‑19 delivers enhanced torque capability and productivity, underscoring Xtrutech’s commitment to innovation and sustainability.

U.S. Twin Screw Extruders Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 494.7 million

Revenue forecast in 2033

USD 673.2 million

Growth rate

CAGR of 3.9% from 2025 to 2033

Actual data

2021 - 2024

Forecast period

2025 - 2033

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2033

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, end use

Country scope

U.S.

Key companies profiled

Coperion GmbH; KraussMaffei Group; Leistritz Extrusionstechnik GmbH; Davis Standard.; Bühler Group; Milacron; Baker Perkins; CPM Extrusion Group; Thermo Fisher Scientific Inc.; WENGER MANUFACTURING.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

U.S. Twin Screw Extruders Market Report Segmentation

This report forecasts revenue growth at country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2033. For this study, Grand View Research has segmented the U.S. twin screw extruders market report based on product, and end use:

-

Product Outlook (Revenue, USD Million, 2021 - 2033)

-

Co-rotating Twin Screw Extruders

-

Counter-rotating Twin Screw Extruders

-

-

End Use Outlook (Revenue, USD Million, 2021 - 2033)

-

Plastic & Polymer Processing

-

Food Processing

-

Pharmaceutical

-

Chemical

-

Rubber

-

Other

-

Frequently Asked Questions About This Report

b. The U.S. twin screw extruders market size was estimated at USD 478.5 million in 2024 and is expected to be USD 494.7 million in 2025.

b. The U.S. twin screw extruders market, in terms of revenue, is expected to grow at a compound annual growth rate of 3.9% from 2025 to 2033 to reach USD 673.2 million by 2033.

b. Co-rotating twin screw extruders dominate the U.S. market and accounted for 71.5% share, due to their superior mixing capabilities and consistent processing output. These systems are widely used in industries such as plastics, food, and pharmaceuticals for compounding, blending, and devolatilization.

b. Some of the key players operating in the U.S. twin screw extruders market include Coperion GmbH, KraussMaffei Group, Leistritz Extrusionstechnik GmbH, Davis Standard., Bühler Group, Milacron, Baker Perkins, CPM Extrusion Group, Thermo Fisher Scientific Inc., WENGER MANUFACTURING.

b. Key factors driving the U.S. twin screw extruders market include rising demand for high-performance materials across automotive, packaging, and medical sectors. Growing emphasis on sustainable and recycled plastic processing is also boosting adoption. Additionally, advancements in extrusion technology and automation are enhancing production efficiency and output quality.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.