- Home

- »

- Advanced Interior Materials

- »

-

Welding Sticks Market Size And Trends, Industry Report, 2030GVR Report cover

![Welding Sticks Market Size, Share & Trends Report]()

Welding Sticks Market (2025 - 2030) Size, Share & Trends Analysis Report By End Use (Automotive & Transportation, Building & Construction), By Region (North America, Asia Pacific, Europe, Central & South America, Middle East & Africa), And Segment Forecasts

- Report ID: GVR-4-68040-543-6

- Number of Report Pages: 101

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Welding Sticks Market Summary

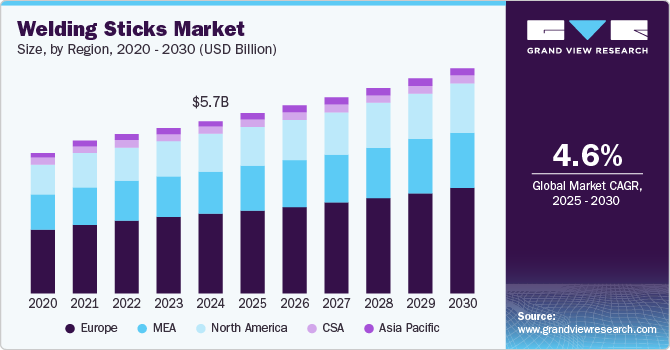

The global welding sticks market size was estimated at USD 5.66 billion in 2024 and is anticipated to reach USD 7.39 billion by 2030, growing at a CAGR of 4.6% from 2025 to 2030. The growing automotive and transportation industries is driving the welding sticks industry growth.

Key Market Trends & Insights

- Europe dominated the welding sticks industry and accounted for the largest revenue share of about 45.57% in 2024.

- Germany welding sticks industry is expected to grow during the forecast period.

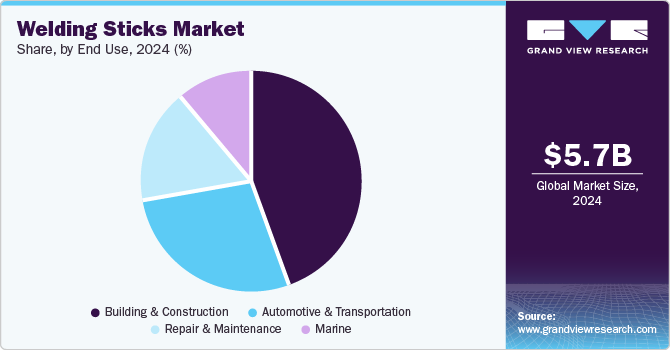

- By end use, the building & construction segment dominated the market and accounted for the largest revenue share of 42.45% in 2024.

Market Size & Forecast

- 2024 Market Size: USD 5.66 Billion

- 2030 Projected Market Size: USD 7.39 Billion

- CAGR (2025-2030): 4.6%

- Europe: Largest market in 2024

The continuous advancements in automobile manufacturing, coupled with the increasing adoption of electric vehicles (EVs), have led to a higher demand for welding processes in vehicle assembly and body fabrication. Furthermore, the aerospace industry relies on welding sticks for aircraft maintenance, repair, and manufacturing, contributing to market expansion.Technological advancements in welding consumables, including the development of high-performance and environmentally friendly welding sticks, are also propelling market growth. Manufacturers are focusing on producing low-emission and high-efficiency welding products to comply with stringent environmental regulations and improve operational efficiency. Additionally, the adoption of automation and robotic welding solutions in manufacturing processes has led to increased consumption of specialized welding sticks.

The oil and gas sector is another key growth driver of the welding sticks industry. With the growing exploration and production activities, there is a rising need for welding solutions in pipeline construction, offshore platforms, and refining units. Similarly, the power generation industry, including renewable energy projects such as wind and solar farms, requires high-quality welding materials for equipment fabrication and maintenance. The increasing investment in energy infrastructure further strengthens the demand for welding sticks.

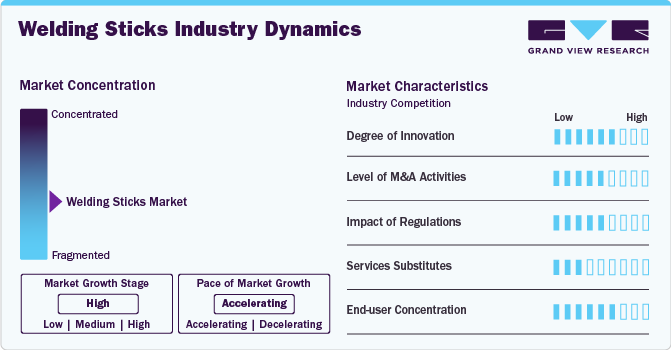

Market Concentration & Characteristics

The global welding sticks market exhibits a moderate to high level of market concentration, with key players dominating the industry through technological advancements, strategic mergers and acquisitions, and extensive distribution networks. Leading manufacturers focus on innovation to enhance the efficiency, durability, and environmental sustainability of welding consumables. The development of low-emission welding sticks and advanced coating technologies reflects a growing emphasis on reducing environmental impact while maintaining high-performance standards. Additionally, mergers and acquisitions have played a crucial role in market consolidation, allowing companies to expand their product portfolios, strengthen their global presence, and enhance their research and development capabilities. These strategic moves also contribute to improving supply chain efficiencies and meeting the evolving demands of industries such as construction, automotive, aerospace, and energy.

Regulatory frameworks significantly influence the welding sticks industry, particularly in terms of safety, emissions control, and quality standards. Stringent environmental regulations regarding welding fumes and hazardous substances have compelled manufacturers to develop eco-friendly alternatives and adhere to occupational safety guidelines. Moreover, the market faces moderate substitution threats from alternative welding technologies, such as laser welding and friction stir welding, which offer precision and efficiency in specific applications. However, the cost-effectiveness and versatility of traditional welding sticks ensure their continued relevance across multiple industries. End-user concentration remains high in sectors like construction, shipbuilding, and heavy machinery manufacturing, where welding plays a crucial role in structural integrity and equipment fabrication. The steady demand from these industries, coupled with ongoing infrastructure projects worldwide, reinforces the stability and growth prospects of the global market.

End Use Insights

The building & construction segment dominated the market and accounted for the largest revenue share of 42.45% in 2024, driven by increasing infrastructure development and rapid urbanization worldwide. Growing investments in residential, commercial, and industrial construction projects, particularly in emerging economies, are driving demand for welding sticks for structural fabrication and metal joining applications. Additionally, government initiatives supporting smart cities, transportation infrastructure, and energy projects contribute to market growth. The rising adoption of advanced welding techniques to enhance structural durability and efficiency further boosts demand. Moreover, stringent building codes and safety regulations necessitate high-quality welding materials, reinforcing the role of welding sticks in modern construction activities.

Automotive & transportation segment is expected to grow significantly at CAGR of 4.7% over the forecast period, driven by the increasing demand for vehicle production and infrastructure development worldwide. Rising automotive sales, coupled with the growing adoption of electric vehicles (EVs), have significantly increased the need for welding processes in vehicle manufacturing and repair. Additionally, advancements in welding technologies, including automation and robotics, have enhanced efficiency and precision, further boosting the adoption of welding sticks.

Regional Insights

Europe dominated the welding sticks industry and accounted for the largest revenue share of about 45.57% in 2024. The European aerospace and defense sector plays a critical role in supporting the market growth. With key aerospace manufacturing hubs in France, Germany, and the United Kingdom, there is a consistent need for high-precision welding solutions in aircraft construction and maintenance. Welding sticks are essential in fabricating aircraft fuselages, engine components, and structural reinforcements, ensuring safety and performance compliance with stringent aviation standards. Furthermore, the defense sector's investments in advanced military equipment and naval vessels contribute to the increasing demand for durable and high-strength welding materials.

Germany Welding Sticks Market Trends

Germany welding sticks industry is expected to grow during the forecast period. Germany’s energy sector, including both traditional and renewable sources, plays a crucial role in the market. The expansion of wind energy projects, particularly offshore wind farms, require high-strength welding materials for turbine construction and maintenance. Similarly, the transition towards hydrogen infrastructure and carbon-neutral energy solutions has led to investments in advanced welding technologies for pipeline construction and storage facilities. The continued reliance on industrial welding for power plant maintenance, whether in conventional or renewable energy sectors, ensures sustained demand for welding consumables.

Asia Pacific Welding Sticks Market Trends

The rapid industrialization and urbanization across Asia Pacific are major growth drivers of the regional welding sticks industry. Countries such as China, India, and Southeast Asian nations are experiencing significant infrastructure development, including the construction of highways, bridges, commercial buildings, and industrial facilities. Government-led initiatives such as China’s Belt and Road Initiative (BRI) and India’s Smart Cities Mission are further accelerating construction activities, leading to a surge in demand for welding consumables, including welding sticks. As large-scale projects require extensive metal fabrication and structural welding, the need for high-quality welding materials is growing, thereby strengthening market growth in the region.

China welding sticks market is expected to witness growth during the forecast period. The growth of China’s shipbuilding and marine industry is playing a significant role in boosting the demand for welding sticks. China leads the world in shipbuilding output, with large-scale shipyards producing commercial vessels, military ships, and offshore platforms. Welding sticks are essential in constructing and maintaining these massive structures, particularly in ensuring durability and resistance to harsh marine environments. Government support and investment in the shipbuilding sector, along with rising global demand for commercial shipping, are expected to sustain the demand for welding sticks in this industry.

North America Welding Sticks Market Trends

The North America welding sticks industry is primarily driven by the region’s extensive infrastructure development and modernization efforts. Government initiatives focused on upgrading transportation networks, including highways, bridges, and railways, have significantly increased the demand for welding consumables. Aging infrastructure in the United States and Canada requires extensive repair and maintenance, creating a sustained need for welding sticks in construction and structural applications. Additionally, large-scale commercial and residential construction projects contribute to market expansion as steel and metal fabrication remain fundamental to modern building designs. The rising trend of prefabrication and modular construction further enhances the demand for welding materials, including welding sticks, to ensure strong and durable joints in structural components.

The automotive and transportation industries serve as key drivers for the U.S. welding sticks industry. The steady increase in automobile production, along with the growing shift toward electric vehicles (EVs), has intensified the need for welding solutions in vehicle assembly, chassis fabrication, and battery enclosures. Automakers are integrating advanced welding technologies to enhance vehicle safety, performance, and durability, further bolstering the demand for welding sticks. Additionally, the U.S. railway sector, which is undergoing modernization efforts, relies heavily on welding consumables for rail track maintenance, locomotive manufacturing, and freight car assembly, reinforcing market growth.

Latin America Welding Sticks Market Trends

The Latin American mining sector is a key driver of the welding sticks industry, as the region is rich in minerals and metals, including copper, iron ore, and lithium. Mining operations require robust welding solutions for equipment fabrication, maintenance, and repair, as heavy machinery, conveyors, and processing plants undergo extreme wear and tear. With increasing investments in mining projects, particularly in Chile, Peru, and Brazil, the need for high-performance welding sticks remains strong. Additionally, the growing adoption of automation and advanced mining technologies has led to increased demand for precision welding solutions in the sector. The expansion of mineral processing plants and infrastructure development in mining regions further supports market growth.

Middle East & Africa Welding Sticks Market Trends

The industrial manufacturing sector in the Middle East and Africa is experiencing significant expansion, driven by efforts to reduce dependency on oil revenues and boost local production. Governments in countries like Saudi Arabia, the UAE, and South Africa are actively promoting industrialization through initiatives such as the UAE’s Operation 300bn and South Africa’s Industrial Policy Action Plan (IPAP). These policies encourage the growth of industries such as metal fabrication, machinery manufacturing, and heavy engineering, all of which rely on welding processes. As manufacturing output increases, the demand for high-quality welding sticks also rises to support metal joining and fabrication requirements across various industries.

Key Welding Sticks Company Insights

Some of the key players operating in market include Lincoln Electric, ESAB

-

Lincoln Electric is a global leader in welding solutions, offering a wide range of welding consumables and equipment. The company provides high-quality welding sticks designed for various applications, including structural welding, pipeline welding, and automotive manufacturing. Lincoln Electric’s welding sticks are known for their superior arc performance, ease of use, and high deposition efficiency.

-

ESAB is a leading provider of welding and cutting solutions, serving industries such as automotive, shipbuilding, and construction. The company offers a comprehensive range of welding sticks, including electrodes for mild steel, stainless steel, and specialized alloys. ESAB’s welding consumables are engineered to deliver excellent weld integrity, improved mechanical properties, and reduced spatter.

-

Illinois Tool Works, Air Liquideare some of the emerging market participants in welding sticks market. Illinois Tool Works (ITW) is a diversified industrial manufacturer with a strong presence in the welding industry. The company’s welding division supplies a variety of welding sticks tailored for different applications, including general fabrication, heavy equipment manufacturing, and oil and gas infrastructure. ITW’s welding consumables are designed for high-strength and corrosion-resistant welds.

-

Air Liquide is a multinational supplier of industrial gases and welding solutions. The company’s product portfolio includes a broad selection of welding sticks for both ferrous and non-ferrous metals. Air Liquide’s welding electrodes are developed to enhance weld quality, reduce porosity, and improve penetration for applications in automotive, construction, and aerospace industries.

Key Welding Sticks Companies:

The following are the leading companies in the welding sticks market. These companies collectively hold the largest market share and dictate industry trends.

- Lincoln Electric Holdings, Inc.

- ESAB Group, Inc.

- Illinois Tool Works Inc.

- Air Liquide S.A.

- Hyundai Welding Co., Ltd.

- Ador Welding Ltd.

- Kobe Steel, Ltd.

- Bohler Welding Group

- Tianjin Bridge Welding Materials Group Co., Ltd.

- Voestalpine Böhler Welding

Welding Sticks Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 5.90 billion

Revenue forecast in 2030

USD 7.39 billion

Growth rate

CAGR of 4.6% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

End use, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; China; India; Japan; Australia

Key companies profiled

Lincoln Electric Holdings, Inc.; ESAB Group, Inc.; Illinois Tool Works Inc.; Air Liquide S.A.; Hyundai Welding Co., Ltd.; Ador Welding Ltd.; Kobe Steel, Ltd.; Bohler Welding Group; Tianjin Bridge Welding Materials Group Co., Ltd.; Voestalpine; Böhler Welding.

Customization scope

Free report customization (equivalent up to 8 analysts’ working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Welding Sticks Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global welding sticks market report based on end use and region:

-

End Use Outlook (Revenue, USD Million, 2018 - 2030)

-

Automotive & Transportation

-

Building & Construction

-

Marine

-

Repair & Maintenance

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

India

-

Australia

-

-

Central & South America

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global welding sticks market size was estimated at USD 5.56 billion in 2024 and is expected to reach USD 5.90 billion in 2025.

b. The global welding sticks market is expected to grow at a compound annual growth rate of 4.6% from 2025 to 2030 to reach USD 7.39 billion by 2030.

b. The building & construction segment dominated the market and accounted for the largest revenue share of 42.45% in 2024, driven by increasing infrastructure development and rapid urbanization worldwide.

b. Some of the key players operating in the Welding Sticks market include Lincoln Electric Holdings, Inc. ESAB Group, Inc. Illinois Tool Works Inc. Air Liquide S.A. Hyundai Welding Co., Ltd. Ador Welding Ltd. Kobe Steel, Ltd. Bohler Welding Group Tianjin Bridge Welding Materials Group Co., Ltd. Voestalpine Böhler Welding.

b. The key factors that are driving the welding sticks market include increasing industrialization, rising construction activities, growing automotive and transportation sectors, advancements in welding technology, and expanding infrastructure development worldwide.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.