Carbon Fiber Reinforced Plastic: Revolutionary Material For Transportation Industry

Stringent regulations related to vehicle CO2 emissions will be widely adopted across the globe.Weight reduction being the key factor for emission control, automakers are facing an urgent need for manufacturing light-weight cars. In such scenario, it is more likely that carbon fiber reinforced plastic (CFRP) will replace high-tension steel.

CFRP structures weigh half of its steel counterparts and around one-third of aluminum. However, irrespective of benefits offered, composites cost are exorbitant as compared to metals, even allowing for their lighter weight. Their use is limited to high-performance vehicles owing to their high prices. The high cost associated with CFRP has limited its usage in performance vehicles such as spacecraft, jet fighters, racing cars, racing yachts, sports cars, and notably Airbus and Boeing airlines.

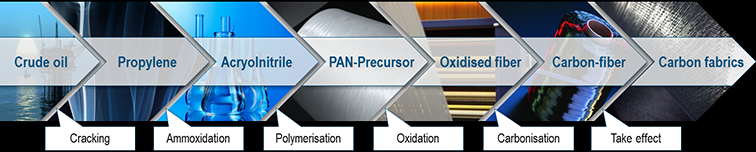

Raw material plays a vital role in CFRP production and its applications. Polyacrylonitrile (PAN) is an important raw material used for carbon fiber production. Different grades of carbon fiber reinforced plastic are used for various applications depending upon the requirements.

High-grade CFRP is required in aerospace and defense applications, while average grade is used for sporting goods and other similar applications. CFRP properties mainly depend on its precursor and production process.

PAN-based CFRP is popularly used on account of its superior qualities over pitch-based CFRP. More than 90% CFRP is produced with PAN as a precursor. PAN is manufactured from acrylonitrile, a chemical intermediate which is produced from propylene.

|

Features |

Function |

|

|

|

|

|

|

High strength to weight ratio for CFRP has made it popular in the aerospace & defense industry. CFRP is popularly used in military planes and helicopters, owing to its ability to reduce a weight of an object to a large extent. Reduction in weight is considered important to increase fuel efficiency and overall performance of these flying machines.

Growth in the aerospace & defense industry in Europe and North America has triggered the CFRP market growth over past few years, a trend which is expected to continue over the forecast period. The presence of aerospace giants such as Airbus and Boeing in Europe and North America has driven the CFRP regional demand.

Global CFRP market is oligopolistic in nature, with top five players holding a majority of the market share. The patented technology available only with the market leaders makes it difficult for a new player to enter the market. The requirement of massive capital investment in plant and R&D restricts new players trying to enter the market. The presence of significant market players increases the industry rivalry.

CFRP market is oligopolistic in nature with top six companies including Toho Tenax Co., Ltd, SGL Group, Toray Industries, Inc., Zoltek Companies, Inc., Mitsubishi Rayon Co., Ltd. and Formosa Plastics accounting for a major share of the global demand. The key trend observed within market players mainly includes mergers and acquisitions. World’s leading carbon fiber manufacturer, Toray, acquired the second leading manufacturer, Zoltek in 2015. SGL group and BMW signed a joint venture for the production of special quality carbon fiber to be used in BMW i3 and BMW i8 models.

In-depth report on global carbon fiber reinforced plastic (CFRP) market by Grand View Research:

In-depth report on global carbon fiber reinforced plastic (CFRP) market by Grand View Research:

https://www.grandviewresearch.com/industry-analysis/carbon-fiber-market