- Home

- »

- Advanced Interior Materials

- »

-

3D Printing Materials Market Size, Industry Report, 2033GVR Report cover

![3D Printing Materials Market Size, Share & Trends Report]()

3D Printing Materials Market (2026 - 2033) Size, Share & Trends Analysis Report By Product (Photopolymers, Thermoplastics, Metals), By Application (Automotive, Aerospace & Defense, Medical, Consumer Products & Industrial), By Region, And Segment Forecasts

- Report ID: GVR-4-68038-080-4

- Number of Report Pages: 90

- Format: PDF

- Historical Range: 2021 - 2025

- Forecast Period: 2026 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

3D Printing Materials Market Summary

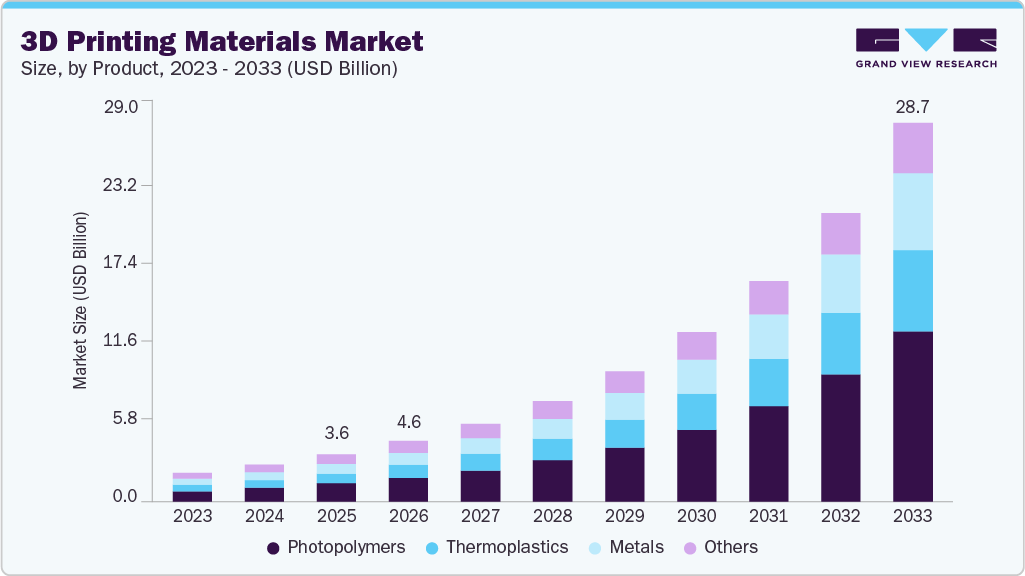

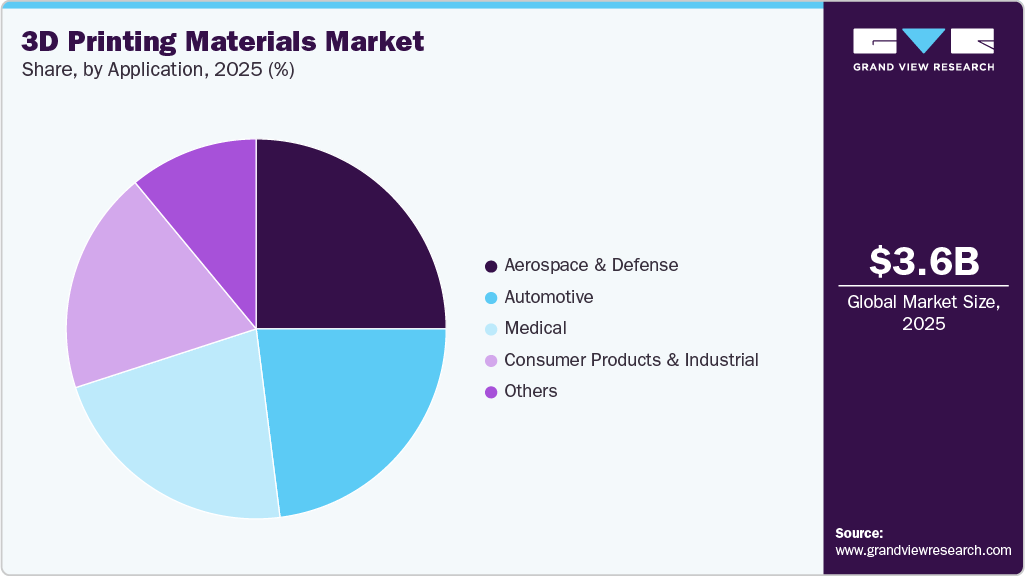

The global 3D printing materials market size was valued at USD 3.58 billion in 2025 and is expected to reach USD 28.68 billion by 2033, growing at a CAGR of 29.9% from 2026 to 2033. Demand for 3D printing materials is rising due to the rapid adoption of additive manufacturing across aerospace, automotive, healthcare, and consumer goods industries.

Key Market Trends & Insights

- North America dominated the 3D printing materials market with the largest revenue share of 39.1% in 2025.

- By product, the photopolymers segment is expected to grow at the fastest CAGR of 32.4% over the forecast period.

- By application, the automotive segment is expected to grow at the fastest CAGR of 31.2% over the forecast period.

Market Size & Forecast

- 2025 Market Size: USD 3.58 Billion

- 2033 Projected Market Size: USD 28.68 Billion

- CAGR (2026-2033): 29.9%

- North America: Largest market in 2025

- Asia Pacific: Fastest growing market

Companies are increasingly using 3D printing for prototyping as well as end-use part production to reduce lead times and development costs. Customization and design flexibility offered by additive manufacturing is accelerating material consumption. Growth in complex geometries and lightweight component requirements is further supporting material demand. The rise of decentralized and on-demand manufacturing is increasing usage of printing filaments, powders, and resins. Small-batch production and mass customization trends are particularly favorable for material suppliers. Increased penetration of industrial-grade 3D printers is also driving higher-volume material usage.3D printing materials are substances used in additive manufacturing to create objects layer by layer, including plastics, metals, and resins. The aerospace sector is increasingly using these materials to produce lightweight components with complex geometries, thereby reducing energy consumption and resource use. This shift leads to fuel savings and facilitates the production of spare engine parts, which require regular replacement due to wear and tear.

In healthcare, 3D printing technology is revolutionizing the production of skin models for pharmaceutical testing, organ replicas for cancer research, and orthopedic implants. By accurately mimicking natural structures, 3D printing enhances research outcomes and enables the creation of customized medical solutions. Moreover, neurosurgeons benefit from 3D-printed models that simulate real patient conditions, improving surgical precision.

Furthermore, emerging trends indicate that innovations in regenerative medicine and personalized implants are expected to drive further growth in the 3D printing materials market. The dental sector is also witnessing a surge in 3D printing applications, including orthodontic devices and prosthetics. As these technologies continue to evolve, they are expected to expand the market's potential across various industries while addressing current challenges related to material costs and accessibility.

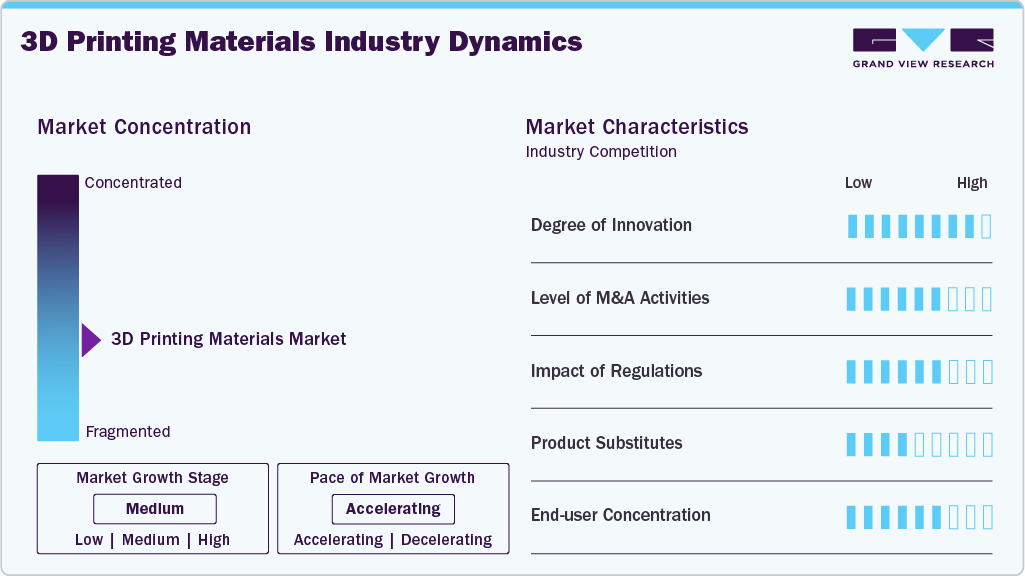

Market Concentration & Characteristics

The 3D printing materials market exhibits moderate concentration, with a mix of global players and specialized material innovators. Large chemical and material companies leverage strong R&D capabilities and global distribution networks. At the same time, niche players focus on application-specific and customized material solutions. Strategic collaborations between printer manufacturers and material suppliers are common. Barriers to entry exist due to technical expertise and certification requirements, especially for aerospace and medical applications. However, innovation-driven startups continue to enter the market.

The threat of substitutes is moderate, as traditional manufacturing materials can replace 3D printing materials in high-volume production. Conventional polymers and metals used in injection molding and machining remain cost-effective at scale. However, substitutes lack the design flexibility and customization advantages of 3D printing materials. Hybrid manufacturing approaches may limit full substitution in some applications. Continuous improvements in material performance are reducing substitution risks. Application-specific benefits such as light weighting and part consolidation strengthen material adoption. As industrial printing scales up, dependence on traditional substitutes is expected to decline.

Product Insights

The photopolymers led the market and accounted for the largest revenue share of 38.6% in 2025. This growth is attributed to their ability to produce complex and intricate designs with high precision. In addition, photopolymers facilitate rapid prototyping and are increasingly utilized in industries such as healthcare and automotive, where detailed models are essential. Their versatility enables the creation of lightweight components that meet stringent performance standards. Furthermore, as demand for high-performance materials rises, photopolymers' ease of use and efficiency are expected to boost their market presence significantly.

Thermoplastics are expected to grow at a CAGR of 30.0% over the forecast period, owing to their low cost and favorable mechanical properties. These materials are highly sought after in the aerospace, automotive, and medical sectors for their lightweight, durable properties. In addition, the ability to produce parts quickly with minimal waste further enhances their appeal, making thermoplastics a preferred choice for manufacturers aiming for cost-effective solutions. Furthermore, as industries continue to adopt 3D printing technologies, the demand for thermoplastics is anticipated to rise, driven by their adaptability and performance in various applications.

Applications Insights

The aerospace and defense sector dominated the market, accounting for the largest revenue share of 24.8% in 2025, driven by the need for lightweight, high-performance components that enhance fuel efficiency and reduce costs. In addition, adopting additive manufacturing allows for the production of complex geometries and customized parts, facilitating rapid prototyping and reducing lead times. Furthermore, with an increasing focus on sustainability and innovation, aerospace manufacturers are leveraging 3D printing technologies to create efficient designs that meet stringent performance standards while minimizing material waste, significantly boosting market demand.

The automotive segment is expected to grow at a CAGR of 31.2% over the forecast period, owing to the industry's shift towards lightweight components and rapid prototyping capabilities. In addition, as manufacturers seek to improve fuel efficiency and reduce production costs, 3D printing enables the creation of intricate designs that traditional methods cannot achieve. Furthermore, the ability to produce custom parts on demand enhances supply chain resilience and reduces inventory costs. Moreover, the automotive industry's increasing investment in advanced materials and technologies further propels the growth of 3D printing applications, making it a vital component in modern vehicle manufacturing.

Regional Insights

North America 3D printing materials market dominated the global market and accounted for the largest revenue share of 39.1% in 2025, attributed to its advanced manufacturing capabilities and technological innovation. In addition, the region benefits from a strong presence of major industry players and extensive investment in research and development. The demand for rapid prototyping and customized solutions across various sectors, including aerospace, healthcare, and automotive, further propels the market. Moreover, supportive government initiatives to enhance manufacturing efficiency contribute to the increasing adoption of 3D printing technologies.

U.S. 3D Printing Materials Market Trends

The 3D printing materials market in the U.S.dominated the North American market and accounted for the largest revenue share in 2025, driven by its robust aerospace and defense industries. The emphasis on lightweight components and rapid prototyping has increased the utilization of 3D printing technologies for manufacturing complex parts. Furthermore, the growing trend of digital manufacturing and customization in various sectors enhances the demand for innovative materials. As companies seek to optimize production processes and reduce costs, the U.S. market is expected to expand significantly in the coming years.

Asia Pacific 3D Printing Materials Market Trends

Asia Pacific 3D printing materials market is expected to grow at a CAGR of 31.1% from 2026 to 2033, owing to a booming automotive industry and increasing urbanization. Countries such as China, Japan, and South Korea are at the forefront of adopting additive manufacturing technologies. In addition, the rising disposable income and demand for customized products drive investments in 3D printing across various sectors. Furthermore, government initiatives promoting research and development further support the rapid expansion of 3D printing applications in this region.

The 3D printing materials market in China is expected to witness substantial growth over the forecast period. This growth is attributed to experiencing rapid growth due to its expanding manufacturing sector and increasing adoption of advanced technologies. In addition, the country focuses on enhancing its aerospace, automotive, and healthcare capabilities through additive manufacturing. As Chinese manufacturers seek to improve efficiency and reduce costs, the demand for high-performance 3D printing materials is expected to rise significantly. Moreover, government support for innovation and technology development is crucial in driving market growth.

Europe 3D Printing Materials Market Trends

Europe 3D printing materials market is expected to grow significantly over the forecast period, owing to is driven by advancements in technology and a strong focus on sustainability across various industries. Countries such as Germany are leading in adopting additive manufacturing technologies due to their robust engineering sector. In addition, the emphasis on reducing waste and improving production efficiency aligns with the principles of 3D printing. Furthermore, increasing investments in research and development foster innovation in material formulations, further propelling the growth of the 3D printing materials market in Europe.

The growth of the 3D printing materials market in Germany is driven by its strong industrial base and commitment to technological advancement. The country's focus on precision engineering and high-quality manufacturing has led to increased adoption of additive manufacturing solutions across sectors such as automotive and aerospace. Furthermore, Germany's initiatives aimed at promoting sustainable practices are enhancing the demand for innovative 3D printing materials that meet stringent environmental standards, thereby contributing to continued market growth.

Latin America 3D Printing Materials Market Trends

Latin America is an emerging market with growing adoption of 3D printing materials. Brazil and Mexico lead regional demand. Use of materials is primarily focused on prototyping and tooling. Limited local production creates opportunities for imports. Government-led innovation initiatives are gradually supporting market growth. Cost sensitivity influences material selection. The region offers long-term growth potential.

Middle East & Africa 3D Printing Materials Market Trends

The Middle East & Africa market is at a nascent but developing stage. Adoption is driven by aerospace, construction, and healthcare projects. Governments are investing in advanced manufacturing hubs. Material demand is primarily met through imports. The focus on specialized and high-value applications is increasing. Training and skill development initiatives support the adoption of new practices. The region shows gradual but steady market expansion.

Key 3D Printing Materials Company Insights

Some of the key companies in the market include ATI, CNPC Powder, GKN Powder Metallurgy, and others. These companies adopt various strategies to enhance their competitive edge. These include launching innovative products that meet evolving industry demands, forming strategic partnerships to leverage complementary strengths, and engaging in mergers and acquisitions to expand their market presence. In addition, companies focus on enhancing customer experience through improved service offerings and integrating advanced technologies, thereby driving growth and fostering collaboration across the 3D printing ecosystem.

-

CNPC Powder offers diverse products, including iron-based, aluminum-based, nickel-based, copper-based, and titanium-based powders. These materials are primarily used in additive manufacturing processes in the aerospace, automotive, and medical industries. Operating in the metal powder segment of the 3D printing materials market, the company focuses on providing innovative solutions that enhance production efficiency and material performance across multiple applications.

-

Colibrium Additive specializes in producing specialized thermoplastics and photopolymers designed for various additive manufacturing processes. The company operates within the polymer segment of the 3D printing materials market, catering to industries such as healthcare, automotive, and consumer products. Colibrium Additive aims to meet the growing demand for customized and efficient 3D printing solutions across diverse applications by focusing on innovation and quality.

Key 3D Printing Materials Companies:

The following key companies have been profiled for this study on the 3D printing materials market.

- ATI

- CNPC Powder

- Colibrium Additive

- GKN Powder Metallurgy

- Höganäs AB

- Kennametal Inc.

- Arkema Inc.

- CRP Technology

- Stratasys Ltd.

- Saudi Basic Industries Corporation (SABIC)

- Polyone Corporation

Recent Developments

-

In February 2025, ATI commissioned its new world-class Additive Manufacturing Products facility in Margate, Florida. The facility integrates design, printing, heat treatment, machining, and inspection for metal additive manufacturing, supporting the production of large, high-performance metal parts that enhance ATI’s materials capabilities for the aerospace and defense markets.

-

In June 2023, CRP Technology announced the launch of Windform XT 2.0 IMG, its first injection molding material made entirely from recycled Windform XT 2.0 industrial 3D printing materials. This high-performance composite, reinforced with carbon fibers and based on nylon PA12, aims to enhance sustainability in industrial production. This innovation enables companies to seamlessly transition from 3D printing prototypes to large-scale injection molding, without compromising performance, while also reducing their carbon footprint by utilizing 100% recycled materials.

3D Printing Materials Market Report Scope

Report Attribute

Details

Market size value in 2026

USD 4.60 billion

Revenue forecast in 2033

USD 28.68 billion

Growth rate

CAGR of 29.1% from 2026 to 2033

Base year for estimation

2025

Historical data

2021 - 2025

Forecast period

2026 - 2033

Quantitative units

Revenue in USD Million and CAGR from 2026 to 2033

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, application, region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; China; India; Japan; Brazil; Argentina

Key companies profiled

ATI; CNPC Powder; Colibrium Additive; GKN Powder Metallurgy; Höganäs AB; Kennametal Inc.; Arkema Inc; CRP Technology; Stratasys Ltd.; Saudi Basic Industries Corporation (SABIC); Polyone Corporation

Customization scope

Free report customization (equivalent to 8 analyst working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global 3D Printing Materials Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and analyzes the latest industry trends in each sub-segment from 2021 to 2033. For this study, Grand View Research has segmented the global 3D printing materials market report based on product, application, and region.

-

Product Outlook (Revenue, USD Million, 2021 - 2033)

-

Photopolymers

-

Thermoplastics

-

Metals

-

Others

-

-

Application Outlook (Revenue, USD Million, 2021 - 2033)

-

Aerospace & Defense

-

Medical

-

Automotive

-

Consumer Products & Industrial

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2021 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.