- Home

- »

- Plastics, Polymers & Resins

- »

-

Heat Resistant Polymer Market Size, Industry Report, 2030GVR Report cover

![Heat Resistant Polymer Market Size, Share & Trends Report]()

Heat Resistant Polymer Market (2025 - 2030) Size, Share & Trends Analysis By Type (Fluoropolymers, Polyamides, Polyphenylene Sulfide, Polyether Ether Ketone), By End Use (Automotive, Industrial), By Region, And Segment Forecasts

- Report ID: GVR-1-68038-873-2

- Number of Report Pages: 80

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Heat Resistant Polymer Market Summary

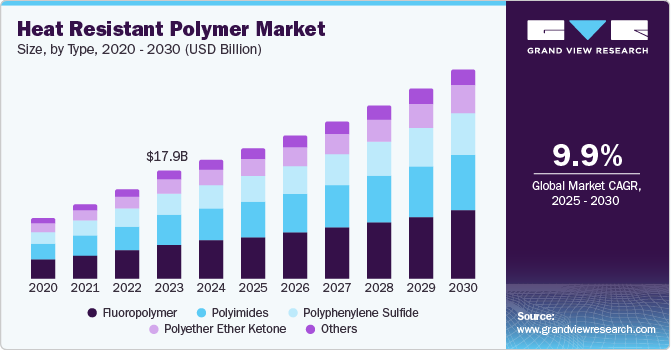

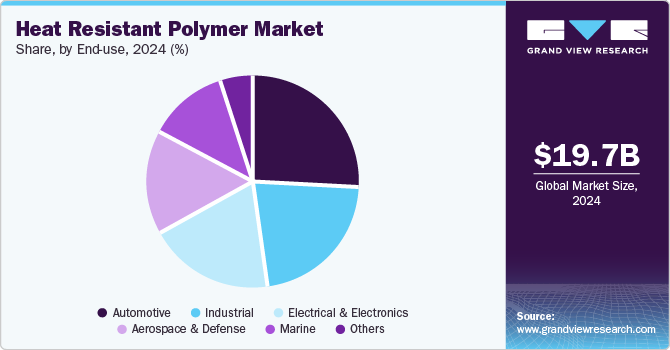

The global heat resistant polymer market size was valued at USD 19.7 billion in 2024 and is projected to reach USD 34.74 billion by 2030, growing at a CAGR of 9.9% from 2025 to 2030. This growth is driven by the increasing demand from the electronics and electrical industries, where these polymers are essential for manufacturing components that can withstand high temperatures.

Key Market Trends & Insights

- North America held a substantial market share in the global heat resistant polymer market revenue in 2024.

- The U.S. dominated the North American heat resistant polymer market in 2024.

- By type, the fluoropolymers segment accounted for over 32.0% of the market revenue in 2024.

- By end use, the automotive segment dominated the market in 2024.

Market Size & Forecast

- 2024 Market Size: USD 19.7 Billion

- 2030 Projected Market Size: USD 34.74 Billion

- CAGR (2025-2030): 9.9%

- Asia Pacific: Largest market in 2024

The shift of the automotive sector towards lightweight and fuel-efficient vehicles has spurred the use of heat-resistant polymers in engine components and under-the-hood applications.

The aerospace industry relies heavily on these materials for their durability and performance in extreme conditions. The advancements in polymer technology and the rising trend of miniaturization in various sectors are propelling market growth. Regulations play a significant role in shaping the global heat resistant polymer market. Stringent environmental policies, such as the European Union’s REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, mandate using safer and more sustainable materials, driving the demand for eco-friendly heat resistant polymers.

In addition, fire safety standards, such as the U.S. UL 94 flammability rating, require materials to meet specific flame retardancy criteria, influencing the development and adoption of flame-retardant polymers. In the automotive sector, regulations to reduce vehicle emissions and improve fuel efficiency, such as the Corporate Average Fuel Economy (CAFE) standards in the U.S., encourage using lightweight, high-performance polymers. These regulatory frameworks ensure safety and environmental compliance and stimulate innovation and growth within the heat resistant polymer market.

Type Insights

The fluoropolymers segment accounted for over 32.0% of the market revenue in 2024, attributed to their exceptional heat and chemical resistance. This makes them valuable in demanding industrial applications, especially in the automotive and aerospace sectors. Their ability to withstand high temperatures without degrading allows them to be used in critical components such as seals, gaskets, and insulation materials, and the increasing demand for lightweight materials further bolsters their growth.

The polyamides segment is expected to grow at a CAGR of 9.9% from 2025 to 2030. Polyamides are increasingly utilized in automotive components, electrical insulation, and industrial machinery due to their ability to perform well under high temperatures and stress conditions. Their versatility allows them to be engineered for specific applications, making them suitable for a wide range of end-user industries.

End Use Insights

The automotive segment dominated the market in 2024. Heat resistant polymers are extensively used in various automotive applications, including under-the-hood components such as engine covers, air intake manifolds, and radiator end tanks. These polymers offer superior thermal stability, mechanical strength, and chemical resistance, making them ideal for modern vehicles requiring lightweight yet durable materials. In addition, the push towards electric vehicles (EVs) has further fueled the demand for heat resistant polymers, as these materials are crucial for ensuring the safety and efficiency of battery systems and electronic components. The automotive industry’s continuous innovation and focus on improving fuel efficiency and reducing emissions have solidified the role of heat resistant polymers as essential materials in vehicle manufacturing.

The aerospace and defense segment is expected to grow at the fastest CAGR over the forecast period from 2025 to 2030 driven by the aerospace industry’s stringent requirements for materials that can perform reliably under extreme conditions, including high temperatures, pressure, and exposure to aggressive chemicals. Heat resistant polymers are used in various aerospace applications, such as wire insulation, fuel system components, and structural parts, where their exceptional thermal and mechanical properties are critical. The defense sector also relies on these polymers for military vehicles, aircraft, and protective gear applications, where durability and performance are paramount.

Regional Insights

North America held a substantial market share in the global heat resistant polymer market revenue in 2024 owing to the region’s robust industrial base and high demand for advanced materials in sectors such as aerospace, automotive, and electronics. The presence of leading manufacturers and technological advancements further boost the market growth in this region.

U.S. Heat Resistant Polymer Market Trends

The U.S. dominated the North American heat resistant polymer market in 2024 driven by the country’s extensive research and development activities, coupled with a strong focus on innovation. The U.S. market benefits from a well-established infrastructure and a high concentration of end-user industries that require heat resistant polymers for various high-performance applications.

Asia Pacific Heat Resistant Polymer Market Trends

The Asia Pacific region held the largest market share of over 34.0% in terms of revenue in the global heat resistant polymer market in 2024 attributed to the rapid industrialization and urbanization in countries such as China and India. The region’s expanding automotive, electronics, and construction sectors are key drivers of demand for heat resistant polymers. In addition, favorable government policies and investments in infrastructure projects further enhance market growth.

China accounted for a significant share Asia Pacific in 2024, highlighting its pivotal role in the region’s heat resistant polymer market. The country’s large manufacturing base, coupled with significant investments in high-tech industries, drives the demand for these polymers. China’s focus on technological advancements and increasing production capacities also contribute to its leading position in the market.

Europe Heat Resistant Polymer Market Trends

The European heat resistant polymer market is projected to grow at a compound annualgrowth rate (CAGR) of 10.0% from 2025 to 2030 driven by the region’s stringent environmental regulations and the increasing adoption of sustainable materials. Europe’s strong automotive and aerospace industries, along with ongoing research and development efforts, are key factors supporting market expansion.

The UK heat resistant polymer market is experiencing steady growth, driven by the country’s focus on innovation and high-performance materials. The UK’s advanced manufacturing sector and increasing investments in research and development play a crucial role in this growth. In addition, the demand for heat resistant polymers in the automotive and aerospace industries further propels the market forward.

Key Heat Resistant Polymer Company Insights

The heat resistant polymer market is highly competitive, characterized by the presence of several global and regional players striving for technological advancement and market share through product innovation, strategic collaborations, and expansion into emerging markets. Intense competition is driven by increasing demand for lightweight, durable, and thermally stable materials, pushing companies to invest in sustainable and cost-effective solutions. Moreover, smaller firms are entering the market with niche, specialized products, intensifying competition and encouraging further innovation.

-

In May 2023, Solvay launched a new high-temperature resistant and flame-retardant polymer, Xydar LCP G-330 HH, designed specifically for electric vehicle (EV) battery module insulation to enhance passenger safety during battery thermal runaway events. This addition complements Solvay’s broader battery solutions portfolio, reinforcing its commitment to safer, high-performance materials in the e-mobility sector.

Key Heat Resistant Polymer Companies:

The following are the leading companies in the heat resistant polymer market. These companies collectively hold the largest market share and dictate industry trends.

- Daikin Industries Ltd.

- RTP Company

- PBI Advanced Materials Co., Ltd.

- Avient Corporation

- Asahi Kasei Corporation

- Covestro AG

- TER HELL Plastic GmbH

- SONGWON

- Guangdong Yinyang Environment-Friendly New Materials Co., Ltd.

- Mitsui Chemicals

Heat Resistant Polymer Market Scope

Report Attribute

Details

Market size value in 2025

USD 21.65 billion

Revenue forecast in 2030

USD 34.74 billion

Growth rate

CAGR of 9.9% from 2025 to 2030

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Volume in kilotons, revenue in USD million/billion, and CAGR from 2025 to 2030

Report coverage

Volume & revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Type, end use, region

Regional scope

North America; Europe; Asia Pacific; Latin America; MEA

Key companies profiled

Daikin Industries Ltd, RTP Company, PBI Advanced Materials Co.,Ltd.. Avient Corporation,, Asahi Kasei Corporation, Covestro AG, TER HELL Plastic GmbH, SONGWON, Guangdong Yinyang Environment-Friendly New Materials Co., Ltd., Mitsui Chemicals

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Heat Resistant Polymer Market Segmentation

This report forecasts revenue & volume growth of the heat resistant polymer market and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global heat resistant polymer market report based on type, end use and region:

-

Type Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Fluoropolymer

-

Polyphenylene Sulfide

-

Polyimides

-

Polyether Ether Ketone

-

Others

-

-

End Use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Automotive

-

Aerospace & Defense

-

Electrical & Electronics

-

Industrial

-

Marine

-

Others

-

-

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

Russia

-

Denmark

-

Sweden

-

Norway

-

-

Asia Pacific

-

Japan

-

China

-

India

-

Thailand

-

South Korea

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global heat resistant polymer market size was estimated at USD 19.70 billion in 2024 and is expected to reach USD 21.65 billion in 2025.

b. The global heat resistant polymer market is expected to grow at a compound annual growth rate of 9.9% from 2025 to 2030 to reach USD 34.74 billion by 2025.

b. Fluoropolymers segment dominated the heat resistant polymer market with a share of over 32.0% in 2024. This is attributable to the rising demand across automotive, electrical & electronics and construction industry on account of chemical resistance and dimensional stability properties.

b. Some key players operating in the heat resistant polymer market include BASF, Honeywell International Inc., DuPont, Daikin Industries, Evonik Industries AG, DIC Corporation, Celanese Corporation, Solvay S.A., Victrex plc, and Arkema.

b. The heat resistant polymer market is driven by rising demand from aerospace, automotive, and electronics industries due to their ability to withstand extreme temperatures. Additionally, growing emphasis on lightweight, high-performance materials for fuel efficiency and durability boosts market growth.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.