- Home

- »

- Advanced Interior Materials

- »

-

U.S. Tray Former Machines Market, Industry Report, 2033GVR Report cover

![U.S. Tray Former Machines Market Size, Share & Trends Report]()

U.S. Tray Former Machines Market (2025 - 2033) Size, Share & Trends Analysis Report By Machine Type (Fully Automatic, Semi-automatic), By Tray Type (Corrugated Trays, Paperboard Trays), By End-use (Pharmaceuticals, Food & Beverage), And Segment Forecasts

- Report ID: GVR-4-68040-633-9

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2021 - 2023

- Forecast Period: 2025 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

U.S. Tray Former Machines Market Summary

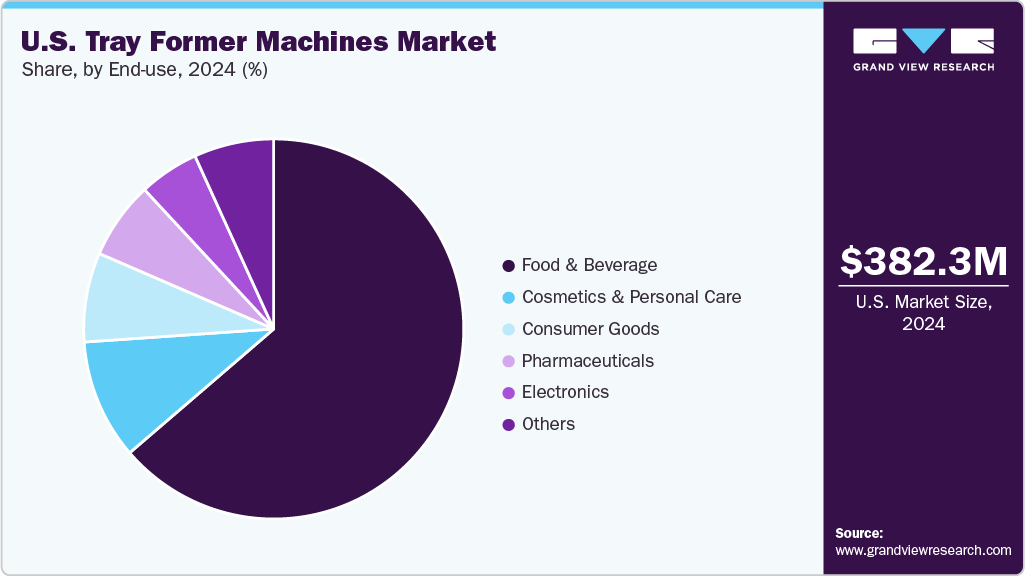

The U.S. tray former machines market size was estimated at USD 382.3 million in 2024 and is projected to reach USD 557.1 million by 2033, growing at a CAGR of 4.5% from 2025 to 2033. The market is experiencing significant growth due to the increasing demand for automated and efficient packaging solutions across various industries.

Key Market Trends & Insights

- The tray former machines market in the U.S. is expected to grow at a substantial CAGR of 4.5% from 2025 to 2033.

- By machine type, the fully automatic segment is expected to grow at a considerable CAGR of 4.8% from 2025 to 2033 in terms of revenue.

- By tray type, the paperboard trays segment is expected to grow at a considerable CAGR of 4.8% from 2025 to 2033 in terms of revenue.

- By end use, the pharmaceuticals segment is expected to grow at a considerable CAGR of 5.4% from 2025 to 2033 in terms of revenue.

Market Size & Forecast

- 2024 Market Size: USD 382.3 Million

- 2033 Projected Market Size: USD 557.1 Million

- CAGR (2025-2030): 4.5%

Technological advancements in tray forming machines, such as high-speed operation and rapid format changeover, enhance production capacity and reduce labor costs. The expansion of the food and beverage sector in the U.S. further drives the demand for tray forming machines, as manufacturers seek efficient packaging solutions to meet consumer preferences for convenience and product safety. The growth of e-commerce also contributes to the market expansion, as robust packaging solutions are required to ensure product safety during transit.

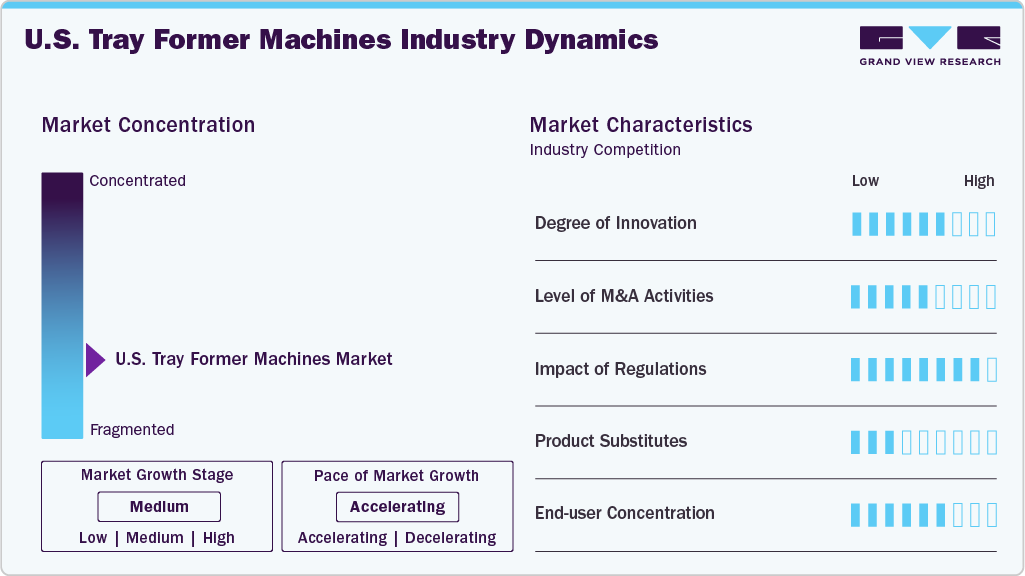

Market Concentration & Characteristics

The U.S. tray former machines market is characterized by a fragmented competitive landscape, with a diverse array of players ranging from large multinational corporations to specialized regional manufacturers.Additionally, the market sees active participation from mid-sized and small enterprises, contributing to innovation and catering to niche applications. This diversity fosters a dynamic environment where companies continually innovate and adapt to meet the evolving demands of sectors like food, beverage, and pharmaceuticals.

The U.S. tray former machines industry exhibits a high degree of innovation, driven by advancements in automation, robotics, and smart technologies. Manufacturers focus on developing machines with faster changeover times, improved accuracy, and energy efficiency. Integration with Industry 4.0 and IoT is becoming common, enhancing real-time monitoring and predictive maintenance. This continuous innovation helps companies meet diverse packaging needs across industries.

The industry experiences a moderate level of mergers and acquisitions (M&A) as companies seek to expand product portfolios, geographic reach, and technological capabilities. Strategic acquisitions enable firms to strengthen their market position and enhance R&D capacities. However, due to the fragmented market structure, many smaller players remain independent, fostering healthy competition. M&A activities often focus on integrating complementary technologies and entering new end-use sectors.

Regulations play a significant role in shaping the tray former machines market, especially concerning environmental standards and food safety. Stringent guidelines on packaging materials, recyclability, and waste reduction drive demand for sustainable and compliant machinery. Compliance with industry-specific regulations, such as FDA requirements for pharmaceuticals and food contact safety, also influences machine design. Manufacturers continuously adapt to evolving regulations to maintain market access and customer trust.

Drivers, Opportunities & Restraints

The U.S. tray former machines market growth is propelled by the increasing demand for automated and efficient packaging solutions across various industries, including food, pharmaceuticals, and consumer goods. Technological advancements, such as high-speed operations and rapid format changeovers, enhance production capacity and reduce labor costs.

Emerging markets with expanding manufacturing bases offer untapped potential for tray forming technology. Countries in Asia-Pacific and Latin America are witnessing a rapid industrialization phase, leading to increased investments in packaging solutions. Additionally, the rising consumer awareness regarding sustainability presents an opportunity for manufacturers to develop eco-friendly tray forming solutions.

High initial investment costs associated with advanced tray forming technologies can deter small and medium-sized enterprises (SMEs) from adopting these solutions. According to a report by the National Small Business Association, around 30% of small businesses struggle with funding for new equipment, which could limit market expansion.

Machine Type Insights

The fully automatic segment accounted for a share of 57.2% in 2024, due to their high efficiency and ability to handle large-scale production demands with minimal human intervention. These machines offer faster operation speeds and consistent quality, which are crucial for industries like food and pharmaceuticals. Automation reduces labor costs and errors, improving overall productivity. Their integration with advanced technologies also supports seamless packaging line automation.

Semi-Automatic segment is expected to grow at a significant CAGR of 4.2% from 2025 to 2033 in terms of revenue. Semi-automatic tray former machines maintain a significant share because they offer flexibility and lower upfront costs, making them suitable for small to medium-sized businesses. They allow manual intervention where needed, which is beneficial for handling customized or lower-volume packaging runs. Semi-automatic systems require less complex infrastructure and are easier to operate, appealing to manufacturers with limited automation budgets. This balance between cost and functionality sustains their demand in the U.S. market.

Tray Type Insights

The corrugated trays segment dominated the U.S. tray former machines industry, accounting for a share of 56.8% in 2024. Corrugated trays maintain dominance in the U.S. tray former machines market due to their robustness, cost-effectiveness, and versatility across various industries. These trays offer superior strength and protection, making them ideal for packaging heavy or fragile items like meats, fruits, and baked goods. Their lightweight nature reduces shipping costs, while their recyclability aligns with growing sustainability demands.

The paperboard trays segment is expected to grow at a considerable CAGR of 4.8% from 2025 to 2033 in terms of revenue. Paperboard trays are experiencing rapid growth in the U.S. market, driven by increasing consumer preference for sustainable and eco-friendly packaging options. These trays are lightweight, recyclable, and biodegradable, making them suitable for packaging ready-to-eat meals, snacks, and pharmaceuticals. The rise in quick-service restaurants and the demand for convenient, single-serve packaging contribute to their popularity.

End-use Insights

The food & beverage segment accounted for a share of 63.7% in 2024, owing to the need for efficient and hygienic packaging solutions. Tray former machines offer advantages such as precise tray formation, high-speed operation, and compatibility with a variety of tray materials, making them ideal for packaging a wide range of food products. The increasing demand for processed and ready-to-eat foods further propels the adoption of tray forming technologies.

The pharmaceutical segment is expected to grow at a considerable CAGR of 5.4% from 2025 to 2033 in terms of revenue. The pharmaceutical industry is experiencing the fastest growth in the tray former machines market, driven by the need for secure and efficient packaging of medications and medical supplies. Tray former machines play a critical role in ensuring the safe and efficient packaging of pharmaceutical products, adhering to stringent industry standards. The increasing demand for pharmaceutical products, coupled with regulatory requirements for packaging, contributes to the growth of this segment.

Key U.S. Tray Former Machines Company Insights

Some of the key players operating in the market include Wayne Automation; Wexxar Packaging, Inc.; and AFA Systems Inc.

-

Wayne Automation is a prominent player in the packaging machinery industry, known for its expertise in designing and manufacturing high-performance case and tray forming equipment. The company serves major sectors such as food, beverage, and consumer goods with a strong focus on automation and reliability. With decades of experience, it has built a solid reputation for delivering customized packaging solutions. Wayne Automation’s industry presence is marked by innovation and long-standing client relationships across North America.

-

Wexxar Packaging, Inc., a division of ProMach, specializes in case and tray forming, sealing, and packaging solutions, primarily for the food, beverage, and healthcare industries. The company is well-regarded for its reliable and flexible machinery that supports both automatic and semi-automatic operations. With a strong footprint in North America and U.S. reach through ProMach’s network, Wexxar emphasizes durability, serviceability, and integration into complex packaging lines. Its solutions cater to both high-volume manufacturers and small-scale operations.

Key U.S. Tray Former Machines Companies:

- Wayne Automation

- Wexxar Packaging, Inc.

- AFA Systems Inc.

- ADCO Manufacturing.

- Combi Packaging Systems, LLC

- Paxiom

- Crown Packaging Corp.

- Sacmi

- DS Smith

- Gietz

Recent Developments:

-

In April 2025, EndFlex unveiled its Vassoyo tray forming machine, engineered specifically for corrugated beverage trays. This advanced equipment features a heavy-duty tubular frame and offers easy changeovers between various tray sizes, enhancing operational flexibility. Equipped with both 1-up and 2-up configurations, it caters to diverse production speeds. An intuitive touchscreen interface provides servicing guides and changeover instructions, streamlining operations and reducing downtime

U.S. Tray Former Machines Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 392.7 million

Revenue forecast in 2033

USD 557.1 million

Growth rate

CAGR of 4.5% from 2025 to 2033

Historical data

2021 - 2023

Forecast period

2025 - 2033

Quantitative units

Revenue in USD million, and CAGR from 2025 to 2033

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Machine type, tray type, end-use

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.

Key companies profiled

Wayne Automation; Wexxar Packaging, Inc.; AFA Systems Inc.; ADCO Manufacturing.; Combi Packaging Systems, LLC; Paxiom; Crown Packaging Corp.; Sacmi; DS Smith; Gietz

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

U.S. Tray Former Machines Market Report Segmentation

This report forecasts revenue growth at the U.S. level and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2033. For this study, Grand View Research has segmented the U.S. tray former machines market report based on machine type,tray type, and end-use:

-

Machine Type Outlook (Revenue, USD Million, 2021 - 2033)

-

Fully Automatic

-

Semi-automatic

-

Manual

-

-

Tray Type Outlook (Revenue, USD Million, 2021 - 2033)

-

Corrugated Trays

-

Paperboard Trays

-

Plastic Trays

-

Others

-

-

End-use Outlook (Revenue, USD Million, 2021 - 2033)

-

Cosmetics & Personal Care

-

Food & Beverage

-

Ready-to-eat meals

-

Meat, poultry & seafood

-

Dairy products

-

Fruits & vegetables

-

Bakery & confectionery

-

Others

-

-

Pharmaceutical

-

Consumer Goods

-

Electronics

-

Others

-

Frequently Asked Questions About This Report

b. The U.S. tray former machines market size was estimated at USD 382.3 million in 2024 and is expected to be USD 392.7 million in 2025.

b. The U.S. tray former machines market, in terms of revenue, is expected to grow at a compound annual growth rate of 4.5% from 2025 to 2033 to reach USD 557.1 million by 2033.

b. Corrugated trays segment accounted for a share of 56.8% in 2024. Corrugated trays maintain dominance in the U.S. tray former machines market due to their robustness, cost-effectiveness, and versatility across various industries.

b. Some of the key players operating in the U.S. tray former machines market include Wayne Automation; Wexxar Packaging, Inc.; AFA Systems Inc.; ADCO Manufacturing.; Combi Packaging Systems, LLC; Paxiom; Crown Packaging Corp.; Sacmi; DS Smith; Gietz

b. The U.S. tray former machines market is primarily driven by the increasing demand for automated and efficient packaging solutions across various industries, including food, pharmaceuticals, and consumer goods.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.