- Home

- »

- Plastics, Polymers & Resins

- »

-

Plastic Processing Machinery Market, Industry Report, 2033GVR Report cover

![Plastic Processing Machinery Market Size, Share & Trends Report]()

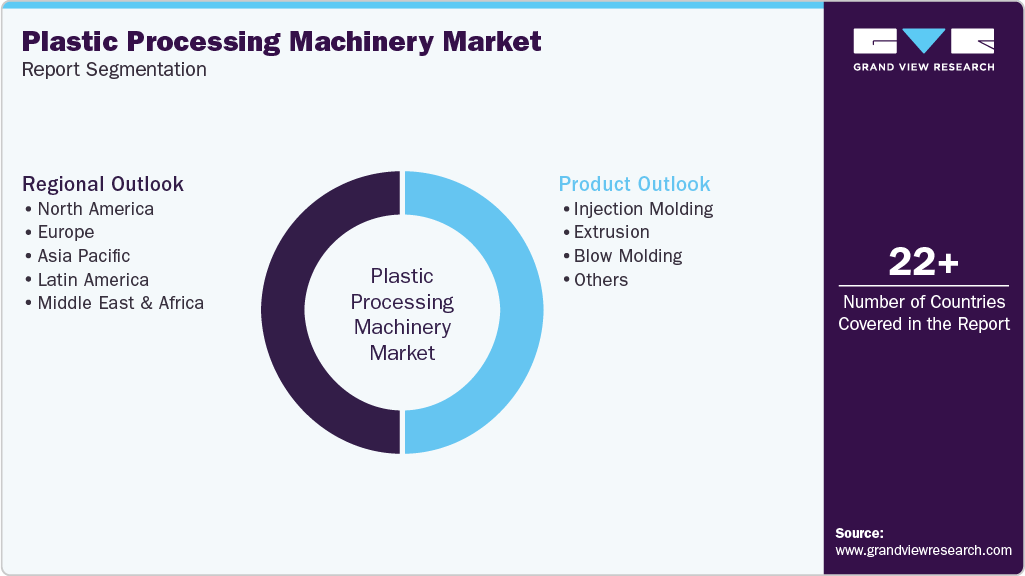

Plastic Processing Machinery Market (2026 - 2033) Size, Share & Trends Analysis Report By Product (Injection Molding, Extrusion, Blow Molding), By Region (North America, Europe, Asia Pacific, Latin America, Middle East & Africa), And Segment Forecasts

- Report ID: GVR-1-68038-671-4

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2021 - 2025

- Forecast Period: 2026 - 2033

- Industry: Bulk Chemicals

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Plastic Processing Machinery Market Summary

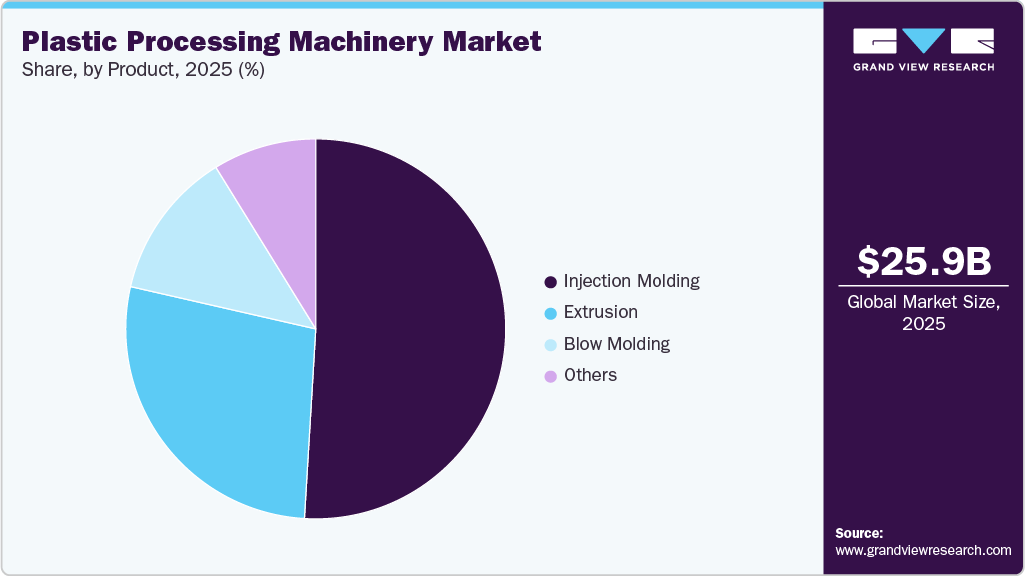

The global plastic processing machinery market size was estimated at USD 25,967.9 million in 2025 and is projected to reach USD 37,890.1 million by 2033, growing at a CAGR of 4.9% from 2026 to 2033. Rising automotive production and the growing use of lightweight plastic components are key drivers for injection molding machinery demand.

Key Market Trends & Insights

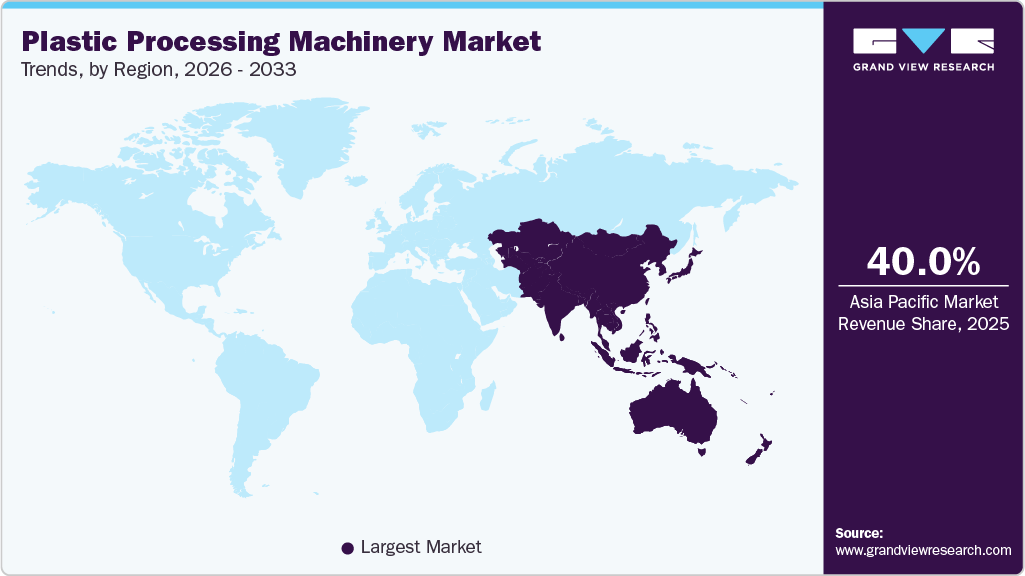

- Asia Pacific dominated the plastic processing machinery industry with the largest revenue share of 40.0% in 2025.

- The plastic processing machinery industry in the U.S. is expected to grow at a substantial CAGR of 4.0% from 2026 to 2033.

- By product, the injection molding segment is expected to grow at a considerable CAGR of 5.2% from 2026 to 2033 in terms of revenue.

Market Size & Forecast

- 2025 Market Size: USD 25,967.9 Million

- 2033 Projected Market Size: USD 37,890.1 Million

- CAGR (2026-2033): 4.9%

- Asia Pacific: Largest market in 2025

Automakers are increasingly replacing metal parts with high-performance plastics to improve fuel efficiency and reduce emissions. Injection molding supports high-volume, precision manufacturing of complex components such as dashboards, bumpers, and interior trims. This trend continues to push investments in advanced molding systems.

Technological advancements in injection molding machinery are further accelerating market growth. The adoption of electric and hybrid machines improves energy efficiency, reduces cycle time, and ensures consistent part quality. Integration of automation and smart manufacturing features helps manufacturers lower labor costs and minimize material waste. These improvements make injection molding equipment more attractive for automotive end users.

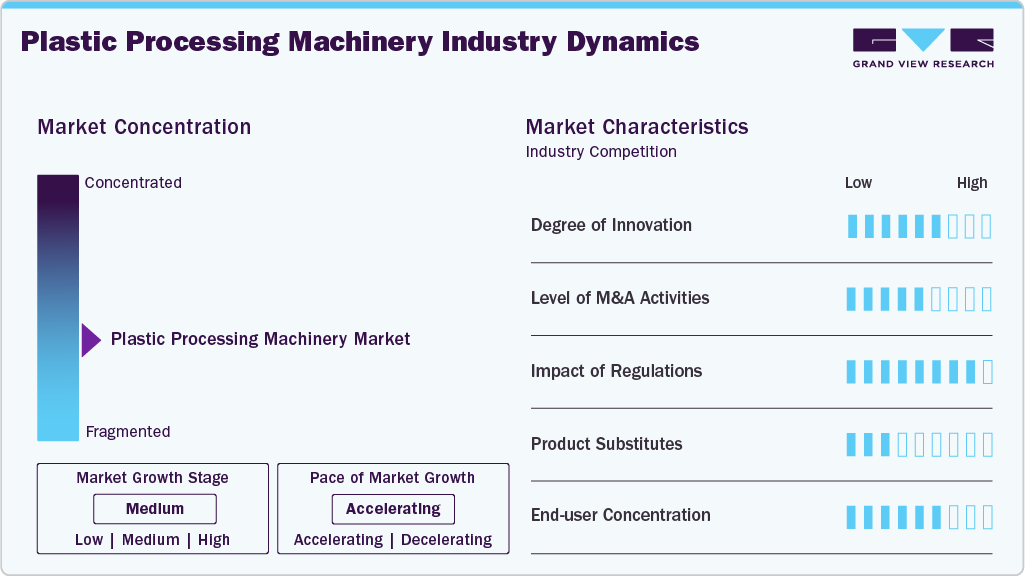

Market Concentration & Characteristics

The plastic processing machinery industry is moderately fragmented, with a mix of global players and numerous regional manufacturers competing across product segments. Large players hold strong positions due to their broad product portfolios, advanced technology, and global service networks. However, mid-sized and local manufacturers remain competitive by offering cost-effective machines and customized solutions. This balance keeps competition active while preventing high market concentration.

Innovation in the plastic processing auxiliary equipment market plays a critical role in overall system performance. R&D initiatives focus on intelligent material handling, drying, feeding, and temperature control solutions that improve material consistency and reduce waste. Smart dryers, gravimetric blenders, automated conveyors, and centralized chilling systems are being integrated with core machines to support high-throughput and multi-material processing environments.

Regulations focused on energy efficiency, worker safety, and plastic waste reduction strongly influence machinery design and adoption. Compliance with emission norms and sustainability standards encourages the use of low-energy and recyclable-material-compatible machines. Manufacturers are adapting equipment to support recycled and bio-based plastics. Regulatory pressure also increases demand for advanced quality control and traceability systems.

End-user demand is moderately concentrated, with automotive, packaging, and consumer goods industries accounting for a major share. Large manufacturers in these sectors often purchase machinery in bulk, giving them strong bargaining power. At the same time, small and mid-sized processors create steady demand for standard machines. This mix results in stable demand across different customer scales.

Drivers, Opportunities & Restraints

Growth in automotive, packaging, and consumer goods manufacturing is a major driver for the plastic processing machinery industry. Rising demand for lightweight, durable, and cost-effective plastic components supports higher adoption of injection molding, extrusion, and blow molding equipment. Automation and energy-efficient machinery help manufacturers improve productivity and reduce operating costs. Expansion of plastic processing capacity in emerging economies further strengthens market growth.

Increasing use of recycled and bio-based plastics creates new opportunities for machinery upgrades and retrofits. Demand for smart, connected machines with digital monitoring and predictive maintenance is growing among processors aiming to optimize output. Rapid development of electric vehicles and sustainable packaging opens new application areas. Replacement of aging machinery in developed markets also offers steady long-term opportunities.

High initial investment and maintenance costs limit adoption among small and medium-sized processors. Volatility in raw material prices can delay capital expenditure decisions by end users. Strict environmental regulations increase compliance costs for machinery manufacturers. Shortage of skilled operators in some regions also restricts efficient utilization of advanced equipment.

Product Insights

Extrusion segment is expected to grow at a significant CAGR of 5.0% from 2026 to 2033 in terms of revenue. Injection molding dominated the market with a 50.9% share in 2025, due to its ability to produce complex, high-precision components at large volumes. It is widely used in automotive, packaging, electronics, and consumer goods manufacturing. High productivity, low material waste, and consistent product quality make it the preferred choice for mass production. Continuous upgrades in electric and hybrid injection molding machines further strengthen its leading position.

Extrusion is growing significantly as demand rises for pipes, profiles, sheets, and films across construction and packaging sectors. Infrastructure development and urbanization are increasing the need for plastic pipes and insulation materials. Advancements in extrusion technology improve output efficiency and material flexibility. Growing use of recycled plastics in extrusion processes also supports strong market expansion.

Regional Insights

North America Plastic Processing Machinery Market Trends

North America plastic processing machinery industry is growing steadily at CAGR of 4.2% over the forecast period, supported by advanced manufacturing practices and high adoption of automation. Strong demand from packaging, automotive, and medical sectors fuels equipment upgrades. Replacement of aging machinery with energy-efficient systems is a key growth factor. Technological innovation and reshoring trends also contribute to market expansion.

U.S. Plastic Processing Machinery Market Trends

The U.S. plastic processing machinery industry dominated the North American market due to its strong automotive, packaging, and medical manufacturing base. High adoption of automation and advanced injection molding technologies supports consistent equipment demand. Ongoing replacement of older machinery with energy-efficient systems drives capital spending. Strong presence of global and domestic machinery suppliers further reinforces market leadership.

Canada is growing steadily, supported by rising demand from packaging, construction, and consumer goods industries. Investments in sustainable manufacturing encourage adoption of energy-efficient plastic processing equipment. Expansion of extrusion and blow molding applications supports machinery sales. Cross-border trade and integration with U.S. supply chains also aid market growth.

Europe Plastic Processing Machinery Market trends

Europe plastic processing machinery industry shows consistent growth driven by strict energy efficiency and sustainability regulations. Manufacturers are investing in electric and hybrid plastic processing machines to meet environmental standards. Automotive and industrial packaging sectors remain key end users. Focus on precision engineering and high-quality output supports stable demand.

Germany plastic processing machinery industry dominated the European market due to its strong engineering base and advanced manufacturing capabilities. The country hosts leading machinery producers and benefits from high demand from automotive and industrial sectors. Focus on precision, automation, and energy-efficient equipment drives continuous technology upgrades. Strong export activity further supports Germany’s leading position.

The plastic processing machinery industry in the UK is growing steadily, supported by demand from packaging, consumer goods, and medical applications. Investments in automation and replacement of aging machinery are improving production efficiency. Sustainability goals are encouraging adoption of energy-efficient plastic processing systems. Expansion of domestic manufacturing and packaging capacity continues to support market growth.

Asia Pacific Plastic Processing Machinery Market trends

Asia Pacific plastic processing machinery industry dominated the market in 2025 with a 40.0% share, due to strong manufacturing activity in China, India, Japan, and Australia. Rapid growth in automotive, packaging, and consumer goods industries drives high machinery demand. Availability of low-cost labor and expanding industrial infrastructure support large-scale investments. The presence of major regional machinery manufacturers further strengthens market leadership.

China plastic processing machinery industry dominated the Asia Pacific market due to its massive manufacturing base and strong presence across automotive, packaging and consumer goods sectors. Large-scale production capacity drives continuous demand for injection molding and extrusion equipment. Local machinery manufacturers offer cost-competitive solutions, supporting high adoption. Ongoing investments in automation and smart factories further strengthen China’s market position.

India plastic processing machinery industry is growing rapidly, driven by expanding packaging, automotive, and construction industries. Rising domestic manufacturing and government support for industrial development are boosting machinery demand. Increased use of plastic products in infrastructure and consumer markets supports extrusion and injection molding growth. Entry of global manufacturers and capacity expansion by local players continue to accelerate market momentum.

Latin America Plastic Processing Machinery Market Trends

The Latin America plastic processing machinery industry is witnessing steady growth, supported by expanding packaging, construction, automotive, and consumer goods industries across key economies such as Brazil and Argentina. Rising demand for flexible and rigid plastic packaging, driven by urbanization, e-commerce growth, and changing consumer lifestyles, continues to underpin investments in injection molding, extrusion, and blow molding machinery. Manufacturers are increasingly focusing on energy-efficient, automated, and digitally enabled machinery to reduce operating costs and improve productivity amid volatile raw material prices and margin pressures.

Brazil plastic processing machinery industry is growing steadily, supported by expanding packaging, automotive, and consumer goods industries. Rising demand for flexible and rigid plastic packaging is driving investment in injection molding and extrusion equipment. Infrastructure development increases the use of plastic pipes and construction materials. Gradual economic recovery and industrial modernization continue to support market growth.

Middle East & Africa Plastic Processing Machinery Market Trends

The Middle East & Africa plastic processing machinery industry is experiencing moderate growth, driven by investments in packaging, construction, and industrial manufacturing, particularly across the Gulf Cooperation Council (GCC) countries and select African economies. Strong demand from food & beverage packaging, petrochemicals, and infrastructure projects continues to support the adoption of injection molding, extrusion, and blow molding machinery.

Saudi Arabia plastic processing machinery industry is emerging as a growing market, supported by diversification of its industrial base beyond oil. Rising demand from packaging, construction, and consumer goods sectors is driving equipment adoption. Government initiatives under industrial development programs encourage local manufacturing and investment in modern machinery. Expansion of petrochemical capacity also supports steady growth in plastic processing activities.

Key Plastic Processing Machinery Company Insights

Some of the key players operating in the market include The Japan Steel Works, Ltd. (JSW), ARBURG GmbH + Co KG and Husky Injection Molding Systems Ltd

-

The Japan Steel Works, Ltd. focuses on large-tonnage injection molding machines designed for automotive and industrial-scale applications. The company is known for its clamping and injection technologies that support high-pressure, high-precision molding. JSW’s equipment is widely used for producing structural and safety-critical plastic components. Strong capabilities in metallurgical engineering enhance machine durability and performance. Its solutions are favored in applications requiring consistent quality over long production cycles.

-

ARBURG GmbH + Co KG specializes in precision injection molding machines optimized for energy efficiency and process control. The company’s systems integrate advanced automation and digital production monitoring. ARBURG machines are commonly used in electronics, medical devices, and technical plastic parts. Emphasis on repeatability and low scrap rates supports high-value manufacturing. Its modular machine design allows customization across diverse end-use requirements.

Key Plastic Processing Machinery Companies:

The following are the leading companies in the plastic processing machinery market. These companies collectively hold the largest market share and dictate industry trends.

- The Japan Steel Works, Ltd.

- ARBURG GmbH + Co KG

- Husky Injection Molding Systems Ltd

- Sumitomo Heavy Industries, Ltd.

- Persimmon Technologies

- Milacron LLC

- Haitian International Holdings Limited

- Chen Hsong Holdings Limited

- ENGEL Austria GmbH

- Nissei Plastic Industrial Co., Ltd.

- Krauss-Maffei Corporation

- Alpha Marathon Film Extrusion Technologies Inc.

- Brown Machine Group

- WITTMANN Technology GmbH (Austria)

- Kautex Maschinenbau System GmbH

Recent Developments

- In June 2025, The Japan Steel Works introduced a new large-tonnage electric injection molding machine aimed at high-load industrial applications. The system is designed to handle large, molded parts while improving energy efficiency. Its electric configuration supports stable operation and precise control during production. This development highlights JSW’s focus on advancing high-capacity, sustainable molding solutions.

- In October 2024, Milacron unveiled the eQ180, an advanced all-electric injection molding machine featuring monosandwich technology. This innovative machine enables efficient production of multi-layer parts using post-consumer recyclable (PCR) materials for enhanced sustainability and performance.

Plastic Processing Machinery Market Report Scope

Report Attribute

Details

Market size value in 2026

USD 27,116.4 million

Revenue forecast in 2033

USD 37,890.1 million

Growth rate

CAGR of 4.9% from 2026 to 2033

Historical data

2021 - 2025

Forecast period

2026 - 2033

Quantitative units

Revenue in USD million/billion and CAGR from 2026 to 2033

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, region

Regional Scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; France; Italy; UK; China; Japan; India; Australia; Argentina; Brazil; Saudi Arabia; South Africa

Key companies profiled

The Japan Steel Works, Ltd.; ARBURG GmbH + Co KG; Husky Injection Molding Systems Ltd; Sumitomo Heavy Industries, Ltd.; Persimmon Technologies; Milacron LLC; Haitian International Holdings Limited; Chen Hsong Holdings Limited; ENGEL Austria GmbH; Nissei Plastic Industrial Co., Ltd.; Krauss-Maffei Corporation; Alpha Marathon Film Extrusion Technologies Inc.; Brown Machine Group; WITTMANN Technology GmbH; Kautex Maschinenbau System GmbH.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Plastic Processing Machinery Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2033. For this study, Grand View Research has segmented the global plastic processing machinery market report based on product and region.

-

Product Outlook (Revenue, USD Million, 2021 - 2033)

-

Injection Molding

-

Injection Molding Machinery, By End Use

-

Automotive

-

Consumer Goods

-

Packaging

-

Electronics

-

Others

-

-

Extrusion

-

Extrusion Machinery, By End Use

-

Construction

-

Consumer Goods

-

Automotive

-

Packaging

-

Others

-

-

Blow Molding

-

Blow Molding Machinery, By End Use

-

Packaging

-

Automotive

-

Electronics

-

Medical

-

Others

-

-

Others

-

Others Machinery, By End Use

-

Packaging

-

Automotive

-

Building & Construction

-

Others

-

-

-

Regional Outlook (Revenue, USD Million, 2021 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

France

-

Germany

-

Italy

-

UK

-

-

Asia Pacific

-

China

-

India

-

Japan

-

Australia

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Saudi Arabia

-

South Africa

-

-

Frequently Asked Questions About This Report

b. Some of the key players operating in the plastic processing machinery market include The Japan Steel Works, Ltd. (JSW), Arburg, Husky Injection Molding Systems, Sumitomo Heavy Industries, Ltd., Persimmon Technologies Corporation, Milacron Holdings Corporation, Haitian International Holdings Limited, Chen Hsong Holdings Limited, ENGEL Austria GmbH, Nissei Plastic Industrial Co., Ltd., Krauss-Maffei Corporation, Alpha Marathon Film Extrusion Technologies Inc.

b. The global plastic processing machinery market, in terms of revenue, is expected to grow at a compound annual growth rate of 4.9% from 2026 to 2033 to reach USD 37,890.1 million by 2033.

b. The global plastic processing machinery market size was estimated at USD 25,967.9 million in 2025 and is expected to be USD 27,116.4 million in 2026.

b. Asia Pacific dominates the plastic processing machinery market in 2025 and accounting for 40.0% share, due to strong manufacturing activity in China, India, Japan, and Australia. Rapid growth in automotive, packaging, and consumer goods industries drives high machinery demand. Availability of low-cost labor and expanding industrial infrastructure support large-scale investments.

b. The plastic processing machinery market is driven by growing demand from automotive, packaging, and consumer goods industries. Rising focus on lightweight materials, automation, and energy-efficient production is increasing adoption of advanced machinery. Expansion of manufacturing capacity in emerging economies further supports market growth.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.