- Home

- »

- Advanced Interior Materials

- »

-

Twin Screw Extruders Market Size, Industry Report, 2033GVR Report cover

![Twin Screw Extruders Market Size, Share & Trends Report]()

Twin Screw Extruders Market (2025 - 2033) Size, Share & Trends Analysis Report By Product (Co-rotating Twin Screw Extruders), By End-use (Plastic & Polymer Processing, Food Processing, Pharmaceutical), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-687-4

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2021 - 2023

- Forecast Period: 2025 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Twin Screw Extruders Market Summary

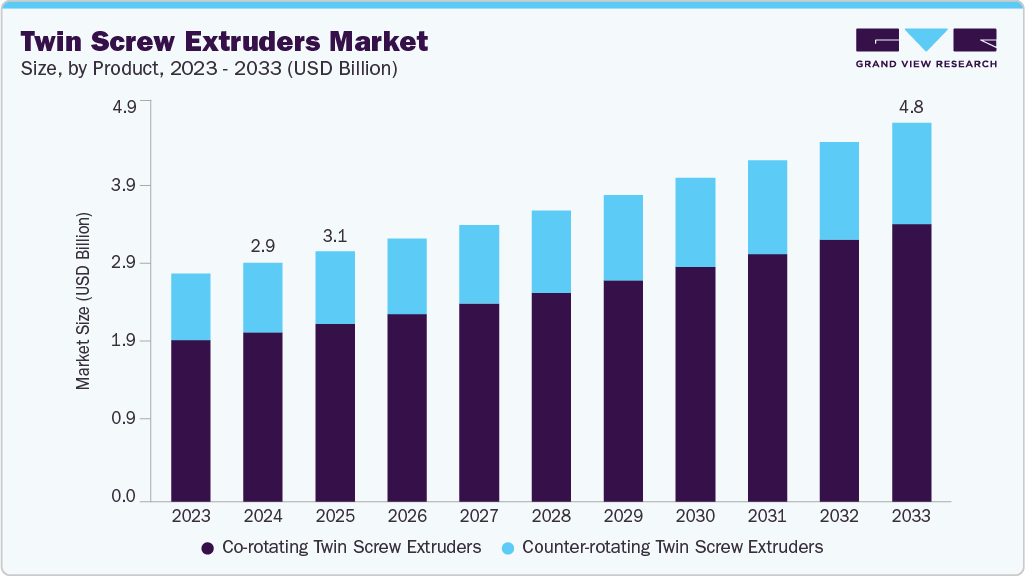

The global twin screw extruders market size was estimated at USD 2,992.6 million in 2024 and is projected to reach USD 4,755.8 million by 2033, growing at a CAGR of 5.3% from 2025 to 2033. The global twin screw extruders industry is primarily driven by the rising demand for high-performance plastic and polymer products across the automotive, packaging, and construction industries.

Key Market Trends & Insights

- Asia Pacific dominated the twin screw extruders market with the largest revenue share of 40.8% in 2024.

- The twin screw extruders market in the U.S. accounted for the largest market revenue share in North America in 2024.

- By product, the co-rotating twin screw extruders segment led the market with the largest revenue share of 71.0% in 2024.

- By end use, the pharmaceutical segment is expected to grow at the fastest CAGR of 6.6% from 2025 to 2033.

Market Size & Forecast

- 2024 Market Size: USD 2,992.6 Million

- 2033 Projected Market Size: USD 4,755.8 Million

- CAGR (2025-2033): 5.3%

- Asia Pacific: Largest market in 2024

These extruders offer better mixing, compounding, and dispersion capabilities, making them ideal for advanced material processing. Furthermore, the increasing application of twin screw extruders in the food and pharmaceutical industries is fueling growth. Their ability to process sensitive materials under controlled conditions enhances product quality and safety. The rising focus on automation and energy-efficient manufacturing systems further supports market penetration. Moreover, the expansion of chemical and rubber processing sectors globally continues to drive consistent demand.

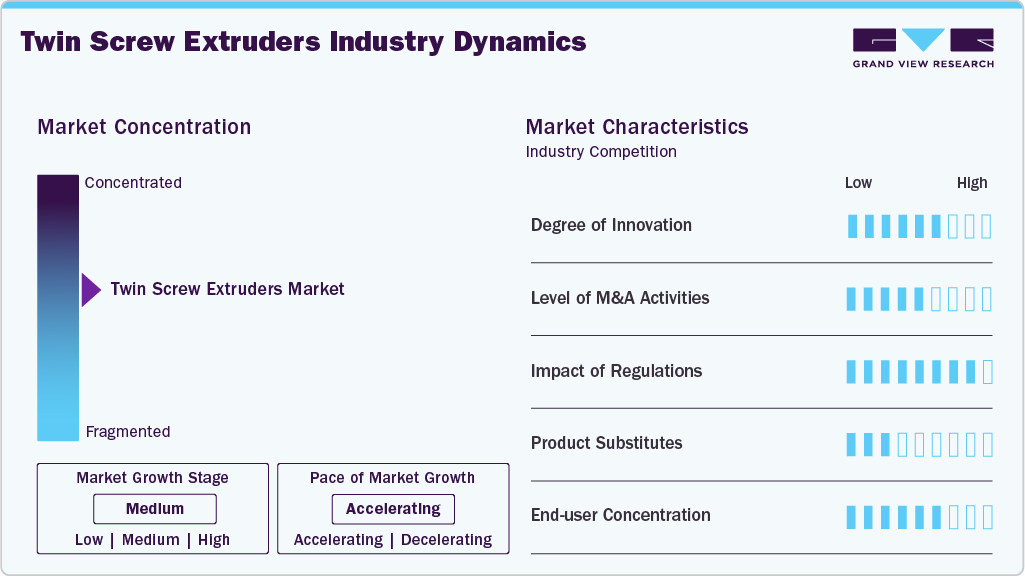

Market Concentration & Characteristics

The global twin screw extruders industry is moderately concentrated, with a few key players holding a significant market share. These companies compete based on technology, product innovation, and global reach. However, the presence of several regional manufacturers adds a level of fragmentation. Continuous R&D and strategic partnerships further influence the competitive landscape.

The twin screw extruders industry is characterized by a high degree of innovation, especially in screw design, control systems, and material flexibility. Manufacturers are focusing on improving energy efficiency, product customization, and processing speed. Advanced features like self-cleaning systems and modular configurations are gaining popularity. Innovation plays a crucial role in maintaining competitiveness and meeting evolving end-user demands.

The market has witnessed a moderate level of mergers and acquisitions, primarily aimed at expanding product portfolios and global presence. Larger companies often acquire regional or specialized players to access new markets and technologies. M&A activities help streamline supply chains and enhance R&D capabilities. Strategic collaborations also support long-term growth and market consolidation.

Regulatory standards related to food safety, pharmaceutical quality, and environmental compliance significantly impact the twin screw extruders industry. Manufacturers must adhere to strict guidelines on material handling and emissions. Compliance drives the adoption of advanced and eco-friendly machinery. Regulations also influence production processes, requiring continuous technological upgrades.

Drivers, Opportunities & Restraints

The growing demand for efficient and continuous processing in industries such as plastics, food, and pharmaceuticals is a key driver for twin screw extruders. Their superior mixing and compounding capabilities enhance product quality. Technological advancements in automation and energy-efficient designs further boost adoption. In addition, increased focus on product customization supports market growth.

Expanding applications in biodegradable plastics and pharmaceutical formulations present promising opportunities for the market. Emerging economies are witnessing rapid industrialization, driving the need for advanced extrusion systems. Innovations in modular and flexible machine designs are creating new growth avenues. Rising investments in R&D and smart manufacturing also offer future potential.

High initial investment and maintenance costs can limit adoption, especially among small-scale manufacturers. Complex machine operation requires skilled labor, which may not be readily available in all regions. Regulatory compliance adds to operational challenges and costs. Furthermore, fluctuations in raw material prices can impact production economics.

Product Insights

The co-rotating twin screw extruders segment led the market with the largest revenue share of 71.0% in 2024. Co-rotating twin screw extruders dominate the market due to their excellent mixing, self-cleaning, and degassing capabilities. They are widely used in plastic compounding, masterbatch production, and food processing. Their high throughput and flexibility make them ideal for continuous and complex processing tasks. Demand remains strong due to their efficiency and ability to handle diverse materials.

Counter-rotating twin screw extruders segment is expected to grow at the fastest CAGR of 4.5% from 2025 to 2033, particularly in PVC and profile extrusion applications. Their ability to operate at lower shear rates makes them suitable for heat-sensitive materials. These extruders provide better pressure build-up and are ideal for forming rigid products. Increasing use in building materials and pipe manufacturing is driving their adoption.

End-use Insights

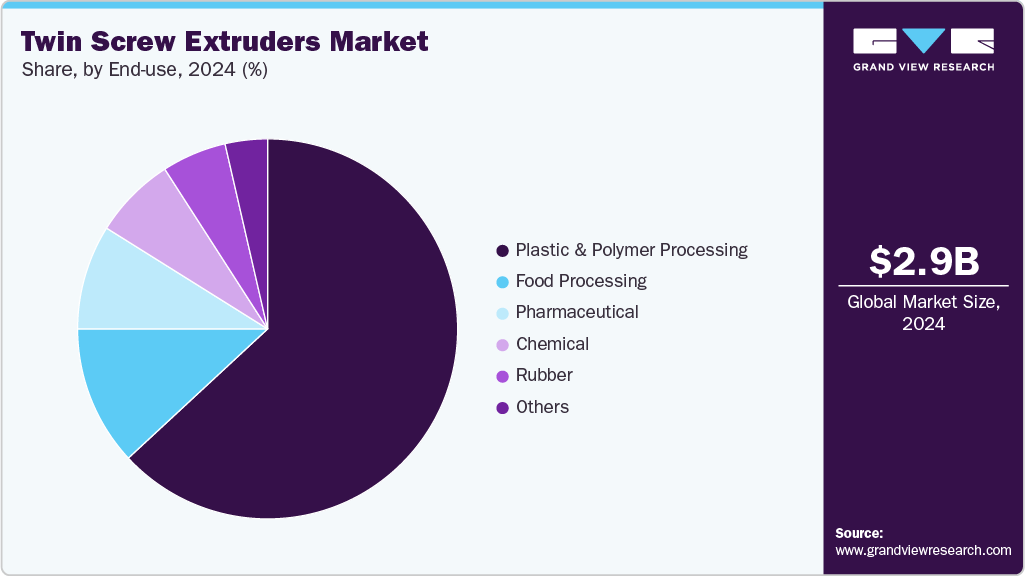

The plastic & polymer processing segment led the market with the largest revenue share of 63.1% in 2024, due to high demand across automotive, construction, and packaging industries. These extruders offer superior blending, dispersion, and melt homogeneity, essential for producing high-quality plastic compounds. Co-rotating types are especially favored for their efficiency in compounding additives, fillers, and colorants. The push for lightweight, durable, and recyclable plastic products further supports their use. Continuous innovation in polymer formulations sustains dominance in this segment.

The pharmaceutical segment is expected to grow at the fastest CAGR of 6.6% from 2025 to 2033, due to the increasing adoption of hot-melt extrusion for drug delivery systems. Twin screw extruders enable precise control over temperature and pressure, making them suitable for processing sensitive active pharmaceutical ingredients (APIs). They help enhance drug solubility and bioavailability, especially in solid dosage forms. The demand for continuous manufacturing and personalized medicine is accelerating their use. Compliance with stringent quality standards also drives the integration of advanced extrusion technology in pharma production lines.

Regional Insights

The twin screw extruders market in North America is anticipated to grow at a significant CAGR of 4.0% during the forecast period, driven by advanced manufacturing technologies and high adoption of automation. The U.S. leads the region with significant investments in the pharmaceutical and polymer processing sectors. Demand for energy-efficient and precision-engineered machinery is driving equipment upgrades. Regulatory standards also encourage the use of high-performance extruders.

U.S. Twin Screw Extruders Market Trends

The twin screw extruders market accounted for the largest market revenue share in North America in 2024, due to its well-established plastic, pharmaceutical, and food processing industries. High adoption of advanced manufacturing technologies and automation supports strong demand. Regulatory emphasis on quality and efficiency encourages the use of precision-engineered extruders. Continuous R&D investment by major players further strengthens market leadership.

The Canada twin screw extruders market is witnessing steady growth, driven by expanding pharmaceutical and packaging sectors. Increased focus on sustainable manufacturing and recycling processes is fueling demand for modern extrusion systems. Government support for industrial innovation and clean technologies also plays a key role. Imports of high-performance extruders are rising to meet evolving industry requirements.

Europe Twin Screw Extruders Market Trends

The twin screw extruders market in Europe maintains a mature but stable market presence, with a strong emphasis on sustainability and technological innovation. The region's established plastics and chemical industries contribute significantly to demand. Manufacturers are focusing on eco-friendly and recyclable material processing. Increasing regulatory compliance continues to shape machinery design and application.

The Germany twin screw extruders market accounted for the largest market revenue share in Europe in 2024, driven by its advanced engineering and strong presence in plastics and chemical manufacturing. The country's focus on precision machinery and automation supports consistent demand. Growth is further supported by innovations in sustainable materials and recycling technologies. Strong export capabilities also contribute to the expansion of its extrusion equipment sector.

The twin screw extruders market in the UK is experiencing growth, due to rising demand in the food processing, pharmaceutical, and packaging industries. Investments in modernizing production facilities and adopting energy-efficient technologies are boosting equipment upgrades. Government regulations promoting sustainable manufacturing also support market expansion. In addition, R&D in biodegradable plastics and specialty pharmaceuticals drives further adoption.

Asia Pacific Twin Screw Extruders Market Trends

Asia Pacific dominated the twin screw extruders market with the largest revenue share of 40.8% in 2024, driven by rapid industrialization and expanding manufacturing sectors in countries like China, India, and Japan. The region benefits from strong demand in plastic processing, automotive, and pharmaceutical industries. Government initiatives supporting infrastructure and localized production are further boosting equipment adoption. Availability of low-cost labor and raw materials enhances market competitiveness.

The twin screw extruders market in China is witnessing significant growth, due to its large-scale plastic and polymer production. The country’s expanding automotive, construction, and packaging sectors are driving demand for high-capacity extrusion equipment. Government initiatives promoting industrial automation and advanced manufacturing technologies further support market expansion. In addition, the presence of numerous domestic manufacturers boosts production and innovation in extruder systems.

The India twin screw extruders market is growing rapidly, fueled by increasing demand in the food processing, pharmaceutical, and plastic industries. The government's “Make in India” initiative and infrastructure development are encouraging local manufacturing. Rising consumption of packaged goods and healthcare products also supports equipment adoption. Moreover, cost-effective labor and a growing industrial base attract global extruder manufacturers to invest in the country.

Middle East & Africa Twin Screw Extruders Market Trends

The twin screw extruders market in the Middle East and Africa is experiencing growing demand due to rising industrial activity and infrastructure development. Countries like the UAE and South Africa are investing in plastics and construction-related manufacturing. Increasing focus on non-oil sectors is boosting the need for modern processing equipment. Market growth is supported by imports and expanding industrial capabilities.

The UAE twin screw extruders market is witnessing growth, due to its strong push toward industrial diversification and localized manufacturing. The country’s strategic location as a regional logistics hub boosts demand for plastic and packaging production. Rising construction activity and infrastructure development are increasing the need for extruded materials such as pipes and profiles. In addition, growing adoption of automated and energy-efficient machinery supports the uptake of advanced extrusion systems.

Latin America Twin Screw Extruders Market Trends

The twin screw extruders market in Latin America is witnessing gradual growth, driven by industrial development in Brazil and Argentina. The region is expanding its presence in the food processing and packaging sectors. Demand for cost-effective and versatile machinery is increasing among local manufacturers. Investment in infrastructure and trade also supports market expansion.

The Brazil twin screw extruders market is experiencing steady growth, due to rising demand from the plastics, chemical, and packaging industries. Increased industrial output and infrastructure development are fueling the need for efficient material processing equipment. The country’s growing food and pharmaceutical sectors are also adopting twin screw extruders for their precision and versatility. Ongoing investments in manufacturing and modernization are further supporting market expansion.

Key Twin Screw Extruders Company Insights

Some of the key players operating in the market include Coperion GmbH, KraussMaffei Group, and Leistritz Extrusionstechnik GmbH.

-

Coperion GmbH specializes in manufacturing high-performance twin screw extruders used across plastics, chemicals, food, and pharmaceutical industries. Their ZSK series co-rotating twin screw extruders are known for superior mixing, compounding, and devolatilization capabilities. The company also offers material handling systems, feeders, bulk solids handling equipment, and complete extrusion lines. Coperion supports custom system integration and advanced control solutions for continuous manufacturing processes. Their technologies are tailored for both standard and highly specialized processing requirements.

-

KraussMaffei Group provides a comprehensive range of twin screw extruders, particularly for applications in PVC, polyolefins, and engineering plastics. Their ZE BluePower series focuses on high-performance compounding with energy-efficient designs and precise temperature control. In addition to extrusion systems, the company delivers injection molding and reaction process machinery. They also offer complete downstream solutions, automation systems, and digital service platforms. KraussMaffei caters to diverse sectors including automotive, construction, medical, and electronics.

Key Twin Screw Extruders Companies:

The following are the leading companies in the twin screw extruders market. These companies collectively hold the largest market share and dictate industry trends.

- Coperion GmbH

- KraussMaffei Group

- Leistritz Extrusionstechnik GmbH

- Japan Steel Works Ltd

- Bühler Group

- Milacron

- Baker Perkins

- Battenfeld-Cincinnati

- CPM Extrusion Group

- Nanjing Jieya Extrusion Equipment Co., Ltd.

- ICMA San Giorgio

- Bausano S.p.A

- Thermo Fisher Scientific Inc.

- WENGER MANUFACTURING

- Xtrutech Ltd.

Recent Developments

-

In July 2025, Coperion introduced its digital platform C‑BEYOND at colorplasticchemie to enable real-time monitoring of ZSK extruders. The system tracks performance, energy use, and emissions to improve planning and maintenance. It also helps reduce downtime and optimize production. Coperion will present it at K 2025 in Düsseldorf.

-

In January 2025, Useon partnered with the National Fund for Innovation to boost its machinery development. The deal includes issuing new shares to support advanced extruder and pelletizer production. This move aims to strengthen Useon’s industrial capabilities. It marks a key step in scaling up innovation and growth.

Twin Screw Extruders Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 3,136.2 million

Revenue forecast in 2033

USD 4,755.8 million

Growth rate

CAGR of 5.3% from 2025 to 2033

Base year for estimation

2024

Historical data

2021 - 2023

Forecast period

2025 - 2033

Quantitative units

Revenue in USD million/billion, and CAGR from 2025 to 2033

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Product, end-use, region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Spain; Italy; China; Japan; India; Australia; South Korea; Brazil; Argentina; Saudi Arabia; South Africa; UAE

Key companies profiled

Coperion GmbH; KraussMaffei Group; Leistritz Extrusionstechnik GmbH; Japan Steel Works Ltd.; Bühler Group; Milacron; Baker Perkins; Battenfeld-Cincinnati; CPM Extrusion Group; Nanjing Jieya Extrusion Equipment Co., Ltd.; ICMA San Giorgio; Bausano S.p.A; Thermo Fisher Scientific Inc.; WENGER MANUFACTURING.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Twin Screw Extruders Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2033. For this study, Grand View Research has segmented the global twin screw extruders market report based on product, end-use, and region.

-

Product Outlook (Revenue, USD Million, 2021 - 2033)

-

Co-rotating Twin Screw Extruders

-

Counter-rotating Twin Screw Extruders

-

-

End-use Outlook (Revenue, USD Million, 2021 - 2033)

-

Plastic & Polymer Processing

-

Food Processing

-

Pharmaceutical

-

Chemical

-

Rubber

-

Other

-

-

Regional Outlook (Revenue, USD Million, 2021 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

France

-

Italy

-

Spain

-

UK

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East and Africa

-

Saudi Arabia

-

South Africa

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global twin screw extruders market size was estimated at USD 2,992.6 million in 2024 and is expected to be USD 3,136.2 million in 2025.

b. The global twin screw extruders market, in terms of revenue, is expected to grow at a compound annual growth rate of 5.3% from 2025 to 2033 to reach USD 4,755.8 million by 2033.

b. Co-rotating twin screw extruders segment led the market and accounted for 71.0% of the global twin screw extruders market revenue in 2024. Co-rotating twin screw extruders dominate the market due to their excellent mixing, self-cleaning, and degassing capabilities. They are widely used in plastic compounding, masterbatch production, and food processing.

b. Some of the key players operating in the global twin screw extruders market include Coperion GmbH, KraussMaffei Group, Leistritz Extrusionstechnik GmbH, Japan Steel Works Ltd., Bühler Group, Milacron, Baker Perkins, Battenfeld-Cincinnati, CPM Extrusion Group, Nanjing Jieya Extrusion Equipment Co., Ltd., ICMA San Giorgio, Bausano S.p.A, Thermo Fisher Scientific Inc., WENGER MANUFACTURING.

b. The global twin screw extruders market is driven by rising demand from the plastics, food, and pharmaceutical industries, where efficient and flexible material processing is essential. Growing emphasis on automation and energy-efficient designs is accelerating adoption, while the increasing focus on sustainable and recyclable materials further fuels market growth.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.